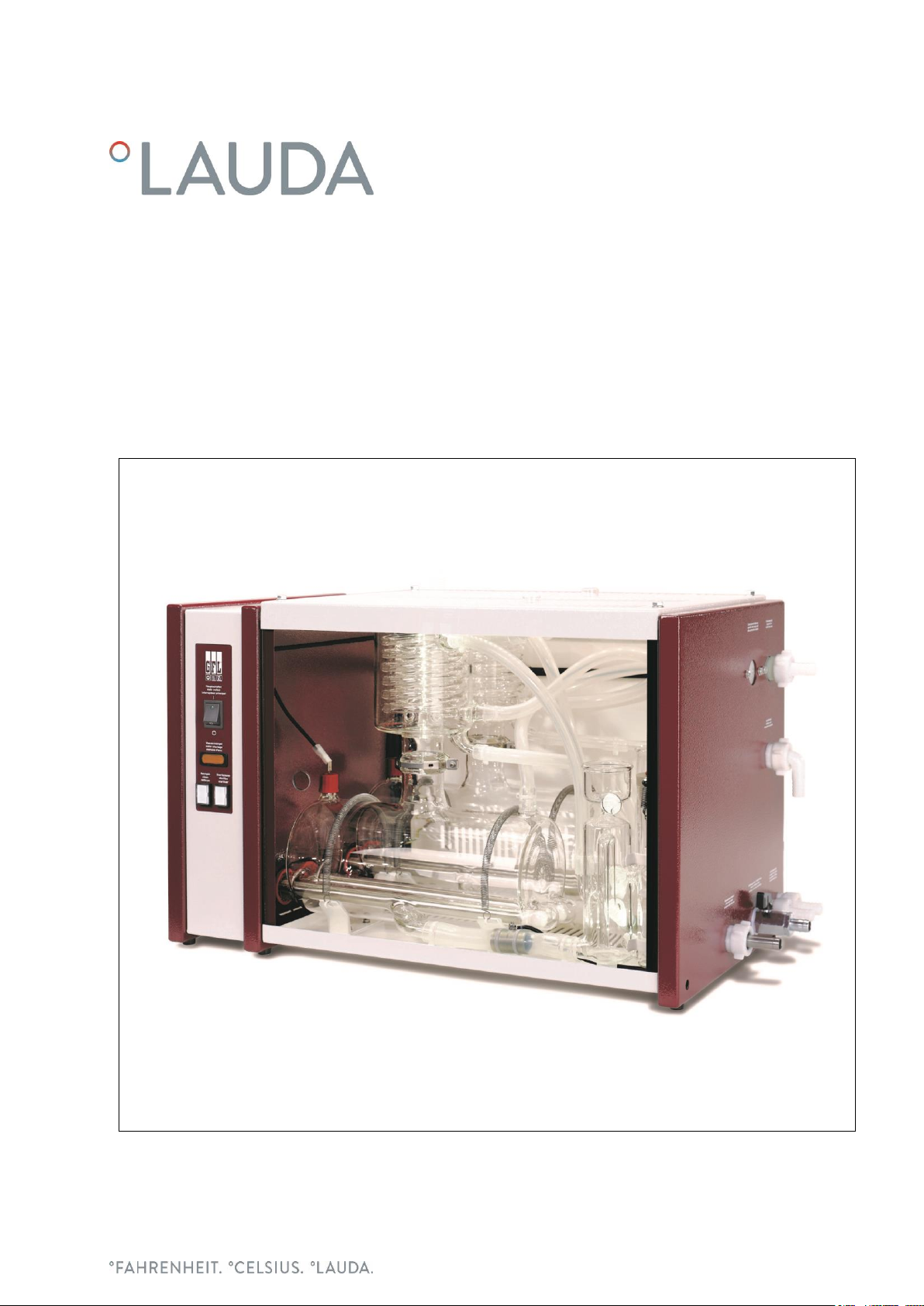

09/2020 Puridest Glass Distillation Apparatus 5 / 34

Content

Operating Instructions .....................................................................................................................................................................1

1Using of the Glass Distillation Apparatus..............................................................................................................................7

Intended Use....................................................................................................................................................................7

Improper Use ...................................................................................................................................................................7

2Warranty ...................................................................................................................................................................................8

3Before Initiation .......................................................................................................................................................................8

4Transport, Set-up and Location of the Distillation Apparatus.............................................................................................8

5Operating Voltage....................................................................................................................................................................9

6Water Connections ...............................................................................................................................................................10

Inlet separate water supply...........................................................................................................................................10

Tap water inlet ...............................................................................................................................................................10

Distillate outlet..............................................................................................................................................................10

Cooling water outlet.....................................................................................................................................................11

Drain Bi-stage boiler ....................................................................................................................................................11

Waste water drain .........................................................................................................................................................11

7Initiation.................................................................................................................................................................................11

8Functional Description .........................................................................................................................................................12

Puridest Glass Distillation Apparatus..........................................................................................................................12

Protection against over-heating in case of low water................................................................................................12

Glass Distillation Apparatus with separate water supply ...........................................................................................12

Glass Distillation Apparatus with level control switch for external storage tank .....................................................12

9Maintenance, Service and Trouble Shooting ......................................................................................................................13

Descaling .......................................................................................................................................................................13

Sterilising .......................................................................................................................................................................13

Water shortage in mono or bi stage ............................................................................................................................14

Pilot lamp "Clean" .........................................................................................................................................................14

10 Disposal of Old Units............................................................................................................................................................15

11 Technical Data .......................................................................................................................................................................16

Puridest Glass Distillation Apparatus models PD 2 G, PD 4 G and PD 8 G.........................................................16

Puridest Glass Bi Distillation Apparatus models PD 2 DG and PD 4 DG .............................................................18

12 Circuit diagram......................................................................................................................................................................19

PD 2 G for 230 V 50 / 60 Hz.................................................................................................................................20

PD 4 G for 230 V 50 / 60 Hz.................................................................................................................................20