Puridest Mono Distillation Apparatus

Contents

Operating Instructions...................................................................................................................................................................1

1 Use of the Distillation Apparatus..........................................................................................................................................7

Intended Use...................................................................................................................................................................................7

1.1

Improper Use..................................................................................................................................................................................7

1.2

2 Warranty................................................................................................................................................................................7

3 Before Initiation.....................................................................................................................................................................8

4 Set-up and Location of the Distillation Apparatus...............................................................................................................8

5 Operating Voltage.................................................................................................................................................................8

6 Water Connections................................................................................................................................................................9

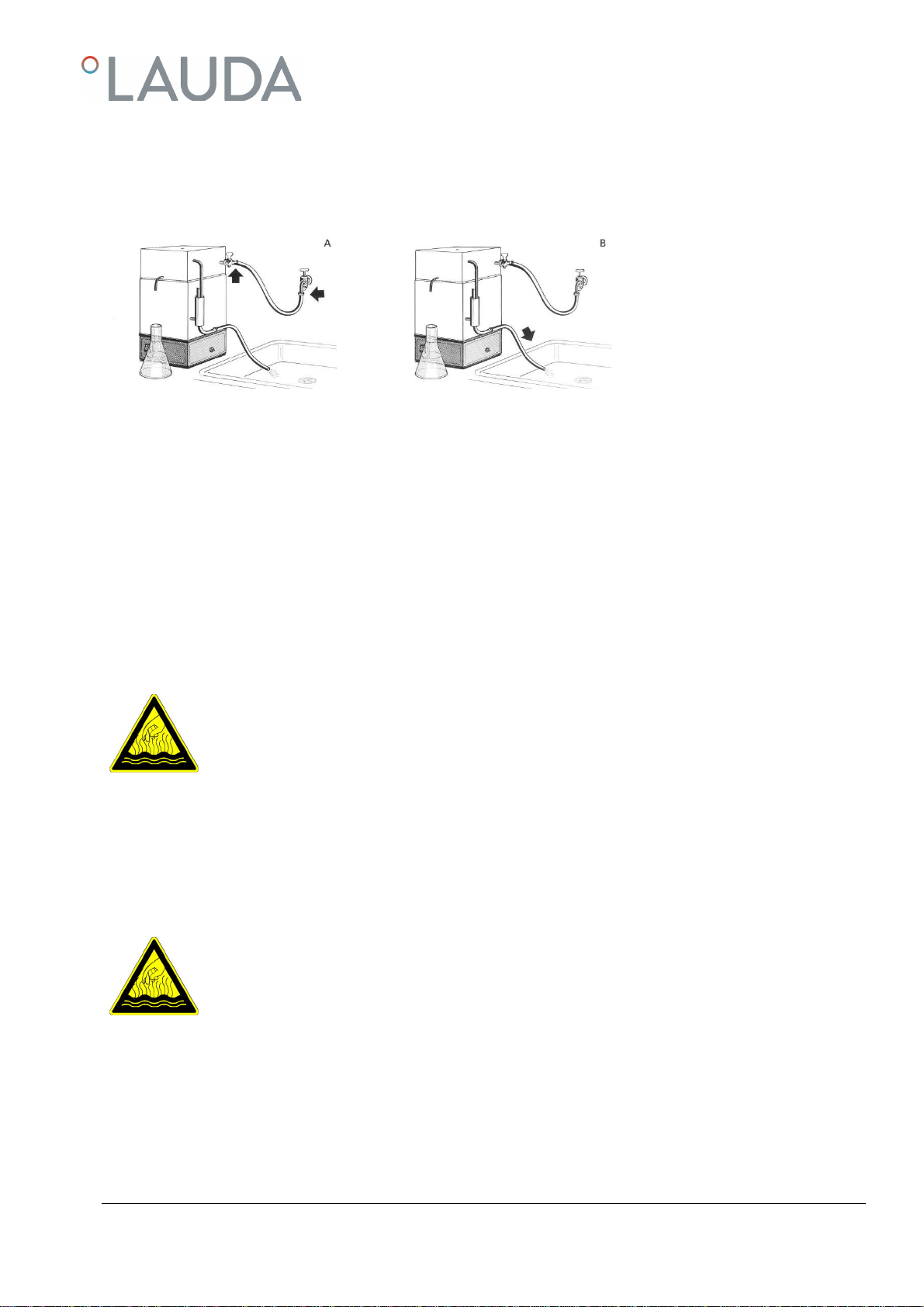

Tap water inlet (ill. A).....................................................................................................................................................................9

6.1

Cooling water outlet (ill. B)...........................................................................................................................................................9

6.2

Destillate Outlet.............................................................................................................................................................................9

6.3

7 Initiation and Setting of the CoolingWaterTemperature.................................................................................................10

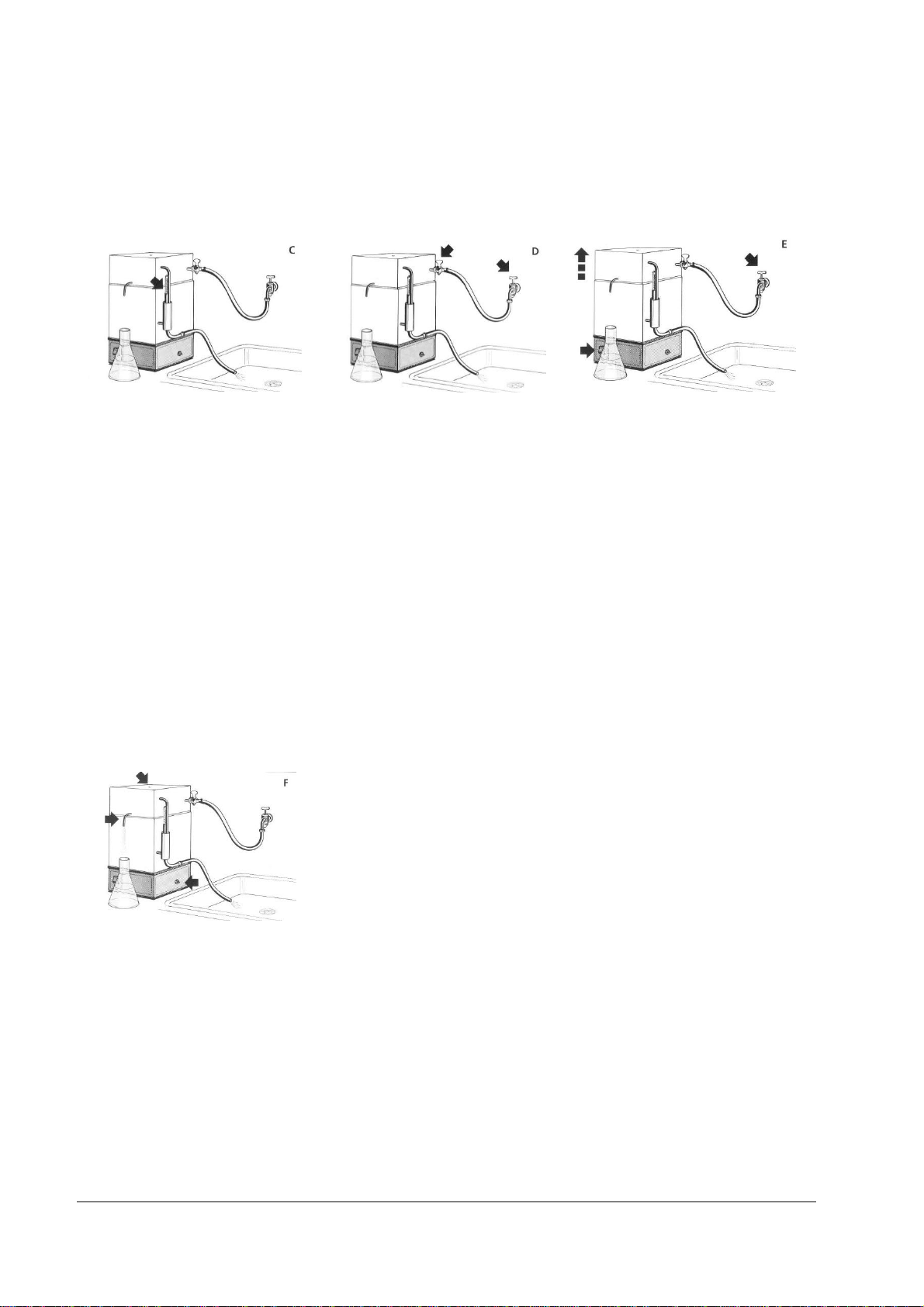

Control Thermometer (ill.C).....................................................................................................................................................10

7.1

Water inlet andSetting the Cooling Water Temperature (ill. D and E).............................................................................10

7.2

Degassing and Distillate Withdrawal (ill. F).............................................................................................................................10

7.3

8 FunctionalDescription.......................................................................................................................................................11

9 Maintenance,Service and Removal of Malfunctions.........................................................................................................11

Descaling........................................................................................................................................................................................11

9.1

Cleaning.........................................................................................................................................................................................12

9.2

Re-Initiation after Low Water....................................................................................................................................................12

9.3

10 Disposal of Old Units..........................................................................................................................................................12

11 TechnicalData....................................................................................................................................................................13

12 Circuit diagram...................................................................................................................................................................14

Circuit diagram PD 2..................................................................................................................................................................14

12.1

Circuit diagram PD 4..................................................................................................................................................................14

12.2

13 Connectionto the mains supply.........................................................................................................................................15

Electrical fuses..............................................................................................................................................................................15

13.1

Examples for connection to the mainssupply.........................................................................................................................16

13.2

14 List of spare parts................................................................................................................................................................ 17

15 Accessories..........................................................................................................................................................................18