Contents

Operating Instructions...................................................................................................................................................................1

1 Use of the Distillation Apparatus..........................................................................................................................................7

Intended Use...................................................................................................................................................................................7

1.1

Improper Use..................................................................................................................................................................................7

1.2

2 Warranty................................................................................................................................................................................7

3 Before Initiation.....................................................................................................................................................................7

4 Transport,Set-up and Location of theShakingApparatus...................................................................................................8

5 Operating Voltage.................................................................................................................................................................8

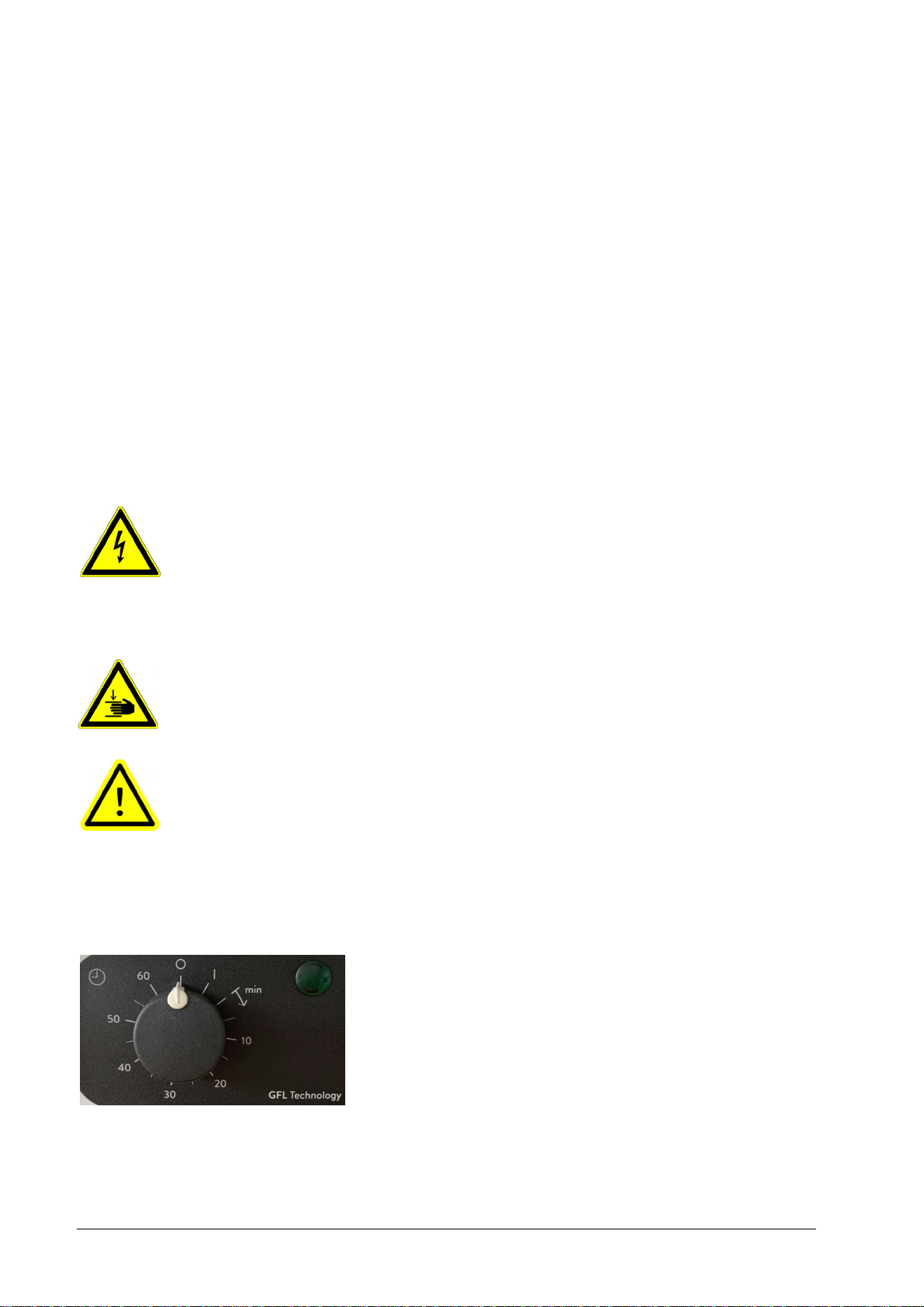

6 Initiation – analogcontrol VS 8 OE, VS 8 BE.....................................................................................................................8

Choosing the operation mode......................................................................................................................................................8

6.1

Choosing the shaking frequency.................................................................................................................................................9

6.2

7 Initiation – digital control VS 8O, VS 8 B,T, R, O, VS 30O ...........................................................................................9

Operation anddisplay elements on the control panel.............................................................................................................9

7.1

Setting shaking frequency and running time...........................................................................................................................10

7.2

Remote control via PC (optional RS 232- interface).........................................................................................................10

7.3

8 Functionaldescription........................................................................................................................................................11

9 Servicing, maintenance and clearingpossible defects........................................................................................................ 11

Exchangingthe fuses...................................................................................................................................................................11

9.1

Breakdown in case of overload and mains failure....................................................................................................................11

9.2

10 Disposal of Old Units.......................................................................................................................................................... 12

11 TechnicalData....................................................................................................................................................................13

Varioshake Shaking Apparatus VS 8 B, VS 8 BE...................................................................................................................13

11.1

Varioshake Shaking Apparatus VS 8 O, VS 8OE.................................................................................................................14

11.2

Varioshake Shaking Apparatus VS 15 O, VS 15B...............................................................................................................15

11.3

Varioshake Shaking Apparatus VS 15 T, VS 15R................................................................................................................16

11.4

Varioshake Shaking Apparatus VS 30 O.................................................................................................................................17

11.5

12 Circuit diagram...................................................................................................................................................................18

Varioshake Shaking Apparatus VS 8 OE, VS 8 BE...............................................................................................................18

12.1

Varioshake Shaking Apparatus VS 15 T, VS 15R, VS 30 O.............................................................................................19

12.2

Varioshake Shaking Apparatus VS 8 O, VS 8 B, VS 15 O, VS15 B...............................................................................19

12.3

13 Connectionto the mains supply......................................................................................................................................... 20

Electrical fuses..............................................................................................................................................................................20

13.1

Examples for connection to the mainssupply.........................................................................................................................21

13.2

14 Lists of spare parts ..............................................................................................................................................................22

Varioshake Shaking Apparatus VS 8 OE, VS 8 BE...............................................................................................................22

14.1

Varioshake Shaking Apparatus VS 8 O, VS 8 B....................................................................................................................23

14.2

Varioshake Shaking Apparatus VS 15 T...................................................................................................................................24

14.3

Varioshake Shaking Apparatus VS 15 R..................................................................................................................................25

14.4

Varioshake Shaking Apparatus VS 15 O, VS 15B...............................................................................................................26

14.5

Varioshake Shaking Apparatus VS 30 O.................................................................................................................................27

14.6

15 Accessories..........................................................................................................................................................................28