Contents

1 Use of the Water Bath...........................................................................................................................................................7

Intended Use...................................................................................................................................................................................7

1.1

Improper Use..................................................................................................................................................................................7

1.2

2 Warranty................................................................................................................................................................................7

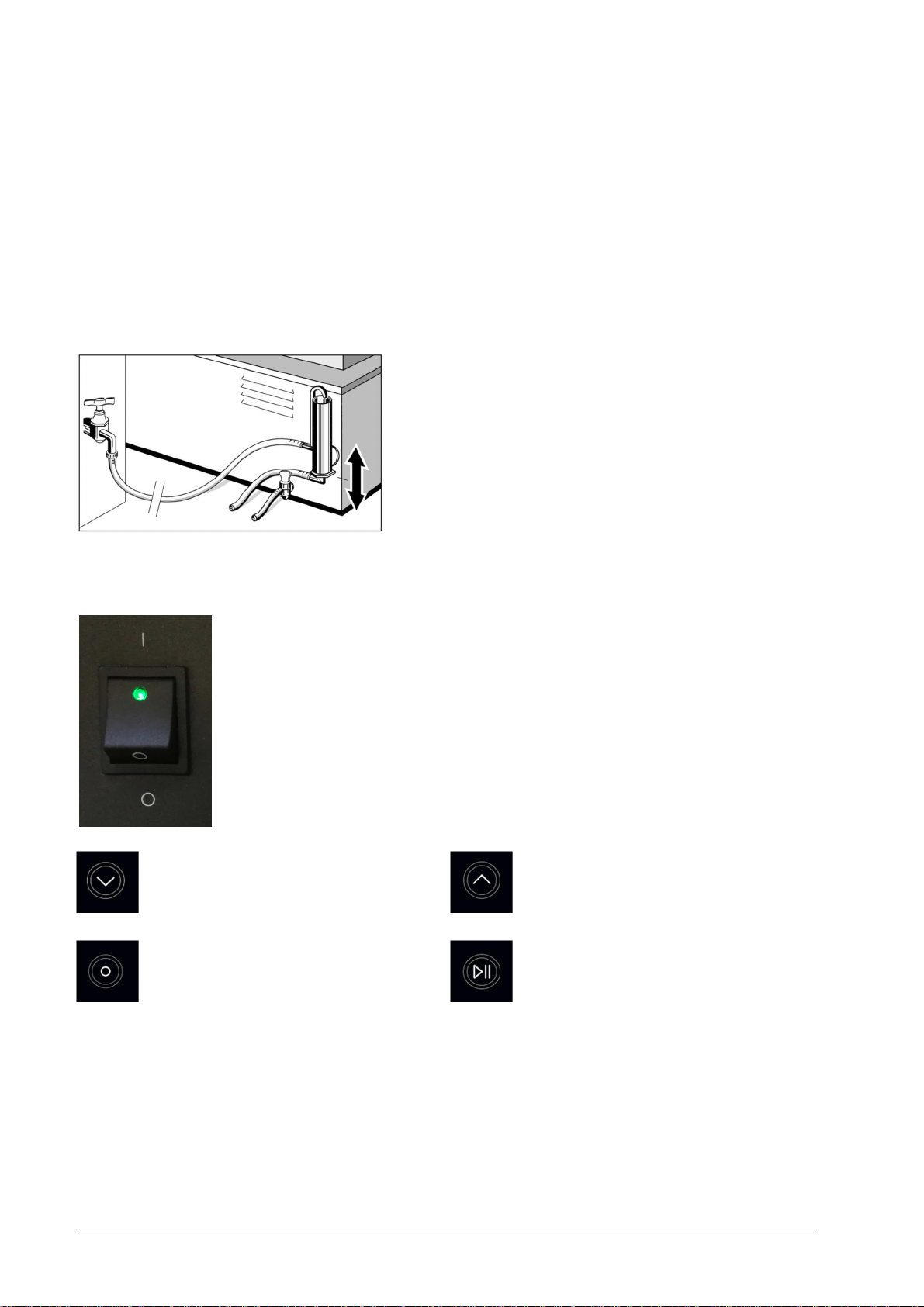

3 Before Installation / Initiation...............................................................................................................................................8

4 Transport,Setup and Location ofthe Water Baths...............................................................................................................8

5 Operating Voltage.................................................................................................................................................................9

6 Filling water into the Water Bath..........................................................................................................................................9

7 Adjustable Water Level Regulator (AccessoryOrder-No. A000024)............................................................................ 10

8 FunctionalDescriptionandInitiation.................................................................................................................................10

Main Menu....................................................................................................................................................................................11

8.1

8.1.1 Setting the required temperature....................................................................................................................................12

8.1.2 Setting the switch-on delay..............................................................................................................................................12

8.1.3 Setting the operation time of Water Bathheating........................................................................................................13

Switching to menu basic settings...............................................................................................................................................13

8.2

8.2.1 Limitation ofthe max. or min. possibletemperature set points in two separate input windows............................15

8.2.2 Setting the trigger points for over- and under-temperature alarms in two separate input windows...................15

8.2.3 Switching between temperature display °C and °F.......................................................................................................16

8.2.4 Start options of the process duration..............................................................................................................................17

8.2.5 Adjusting the actual temperature at a certain set point temperature........................................................................17

8.2.6 Switching back to the main menu....................................................................................................................................18

Display of current process data.................................................................................................................................................18

8.3

Function control with visual and acoustic alarms....................................................................................................................19

8.4

9 Water Circulation (onlyWater Baths models H 8A und Typ H16 A)............................................................................20

10 Maintenance and Support..................................................................................................................................................20

Exchangingthe internal unit fuses.............................................................................................................................................20

10.1

Low water cut-off.........................................................................................................................................................................21

10.2

Under-temperature alarm..........................................................................................................................................................21

10.3

Over-temperature alarm............................................................................................................................................................22

10.4

Temperature sensor is interrupted............................................................................................................................................22

10.5

Temperature sensor has short circuit........................................................................................................................................22

10.6

RemovingLime Deposits, Cleaning and Maintenance..........................................................................................................23

10.7

10.7.1 Descaling..............................................................................................................................................................................23

10.7.2 Cleaning and Maintenance................................................................................................................................................23

10.7.3 Decontamination.................................................................................................................................................................23