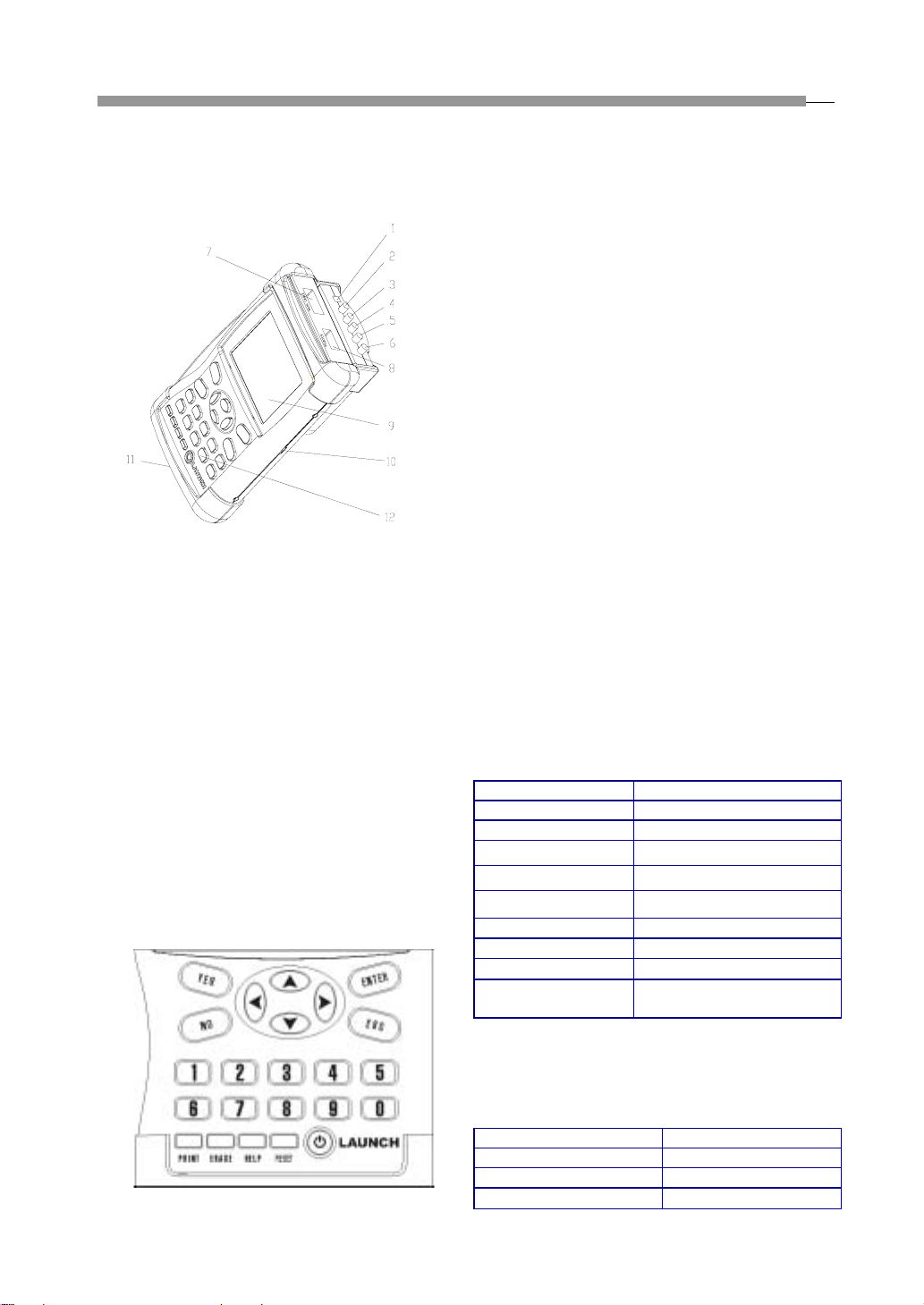

LAUNCH KES-200 4Channel Oscilloscope

B-1

GeneralInformation

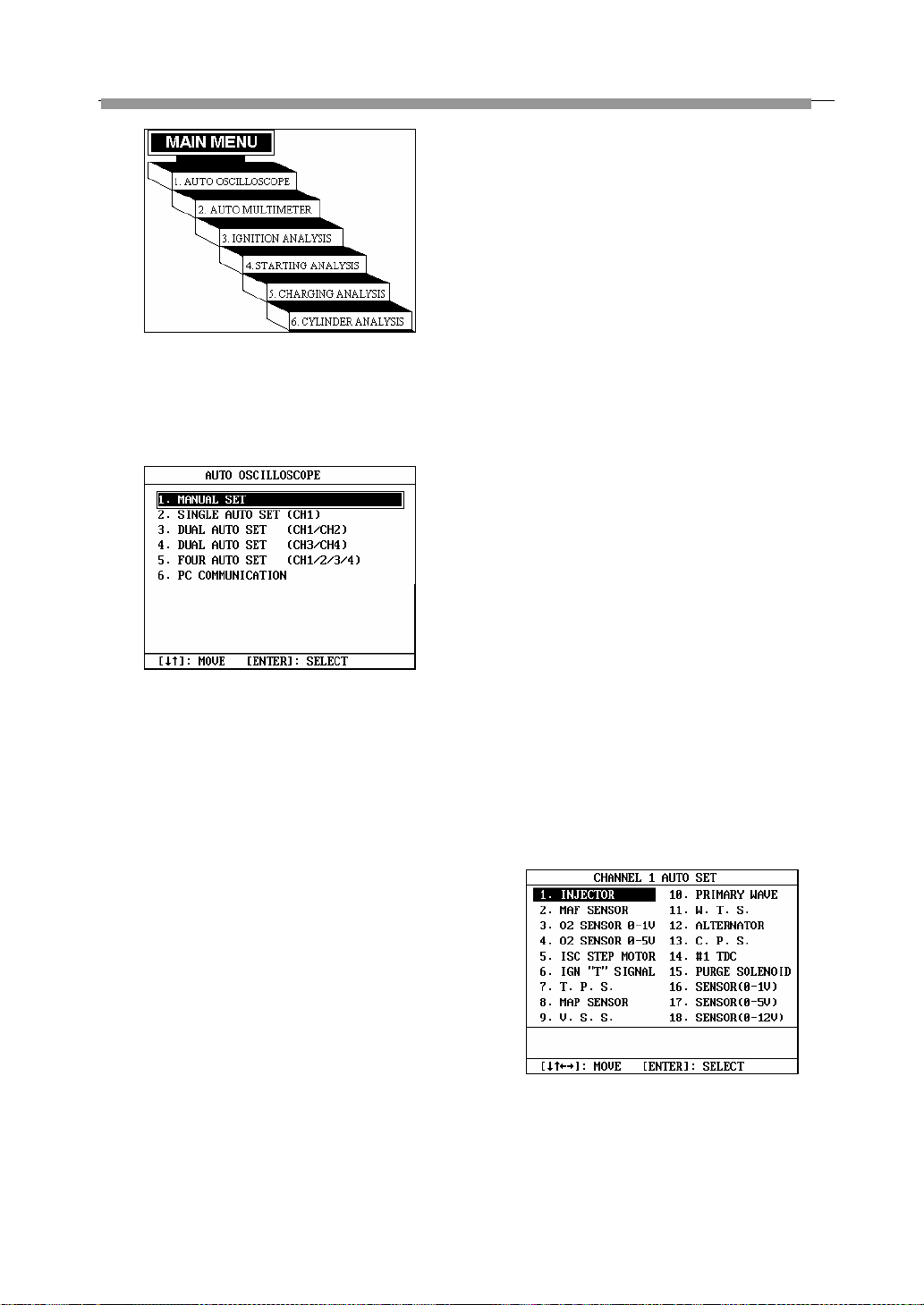

KES-200 is a tool specially designed for engine test and

analysis with the following functions: 4channel

oscilloscope, multimeter, ignition waveform test,

starting systemanalysis, charging systemanalysis,

cylinderanalysis,PClink,printandInternetupdate,

etc.

4channel oscilloscope function can be used to test

the output waveform of automobile sensors. KES-200

has a built-in dynamic memory for saving 50

waveforms, including rich information of standard

waveform of vehicle sensors and repairs.

You can make a comparison between a waveform

being tested and a standard waveform and analyze

sensor troubles. In addition, the test method and

troubleshooting help information have been given for x

types of commonly used sensors.

The oscilloscope has a complete display control mode

capable of displaying 4 tested waveforms at the same

time.

Multimeter function is used mainly for measuring

voltage, current, resistance, output frequency, duty

cycle, battery voltage, tachometer, and intake manifold

vacuum.

Ignition waveform test function can be used to test

the primary and secondary waveforms of gasoline

engine and display them in single cylinder waveform,

parade waveform, raster waveform or bar graph. It can

be used to test ignition systems with or without

distributor, and obtain ignition peak voltage, spark

voltage and spark duration (with distributor). The

system gives standard and faulty primary and

secondary waveforms to help the user to analyze

automotive engine troubles.

Starting system analysis function is mainly used to

test the starting voltage and current of engine system.

Starting voltage test is to test the storage voltage of the

battery while starting, it can display the initial and end

voltage value at same time; the current waveform and

its maximal and minimal value can be displayed while

perform starting current test.

Charging system test function is mainly used to test

the AC charging voltage of the alternator. It can also

test the charging current and engine speed.

Cylinder analysis function includes power balance

test, cylinder efficiency test, and relative cylinder

compression pressure test. Power balance test is

applicable to distributor engines with less than 6

cylinders. This function is used to analyze the uniformity

of each cylinder. Both auto and manual test modes are

provided. Cylinder efficiency test is to judge the power

performance of each cylinder by testing the primary

ignition interval of two cylinders adjacent with each

other. Relative cylinder compression pressure test is

applicable to engines with less than 6 cylinders. This

function is used to analyze the uniformity of

compression pressure of each cylinder.

PC link function can transmit the stored waveform

from KES-200 to PC for further analysis, processing,

print. This function can also used to perform software

update.

KES-200 is also equipped with printer interface, which

supports common printers with PCL language. The

printed result may be used to perform further analysis

and reserve.

KES-200 is easy to operate, for it provides help

information to guide the user how to operate.

KES-200 can be updated quickly and easily through

the Internet. The user may download the latest version

of the test software and update their KES-200 from the

LAUNCH website: http://www.cnlaunch.com, to obtain

the latest test technique of LAUNCH.