10

1

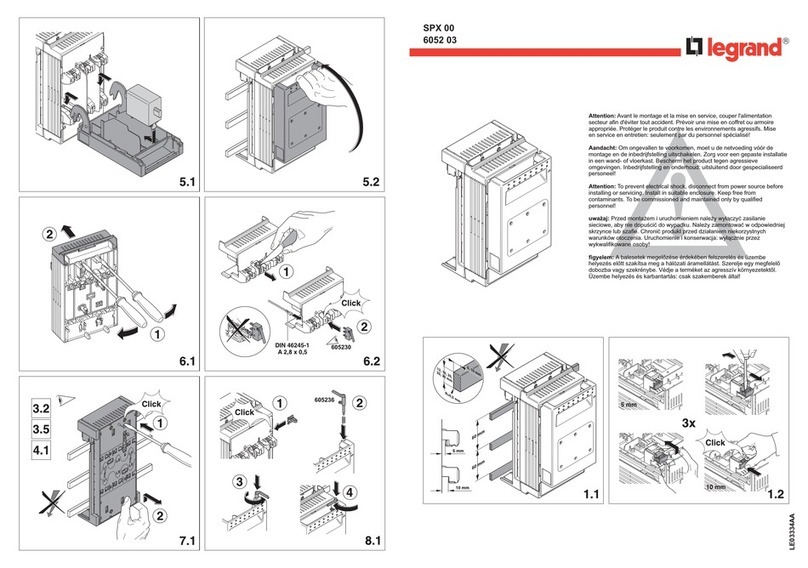

Sujeta cables (OFRWC)

1. Coloque todos los cables en la canaleta para cables.

Introduzca el borde serrado del sujeta cables en la ranura

interior de la base.

2. Gire el borde ondulado del sujetador en su lugar debajo

de la ranura exterior de la base.

2

Canales exteriores

1

1. Coloque todos los cables en la canaleta para cables.

Introduzca el borde serrado del sujeta cables contra la

pared interior del canal.

2. Gire el borde ondulado del sujetador contra la pared

externa del canal y presione por completo.

2

Canales internos

Codo plano (OFR11)

1. Introduzca las pestañas de conexión del codo plano en los

canales exteriores de la base de la canaleta para cables

montada al piso. Ajuste los (2) tornillos n.° 8-32 para fijarlos.

2. Utilizando los sujetadores n.º 8 en los dos orificios de montaje

suministrados, instale la base del codo directamente en la

parte superior de la cubierta del piso existente. El tipo de

tornillo debe ser adecuado para el tipo de piso en el cual se

está instalando la canaleta para cables.

3. Introduzca la próxima sección de la base de la canaleta para

cables en el otro par de pestañas de conexión y fíjela

utilizando los (2) tornillos de montaje n.º 8-32.

4. Sujete las cubiertas de la canaleta para cables a ambas

secciones de la base de la canaleta. Sujete la cubierta del

codo usando 4 tornillos de cabeza redonda n.º 8-32.

1

1

2

3

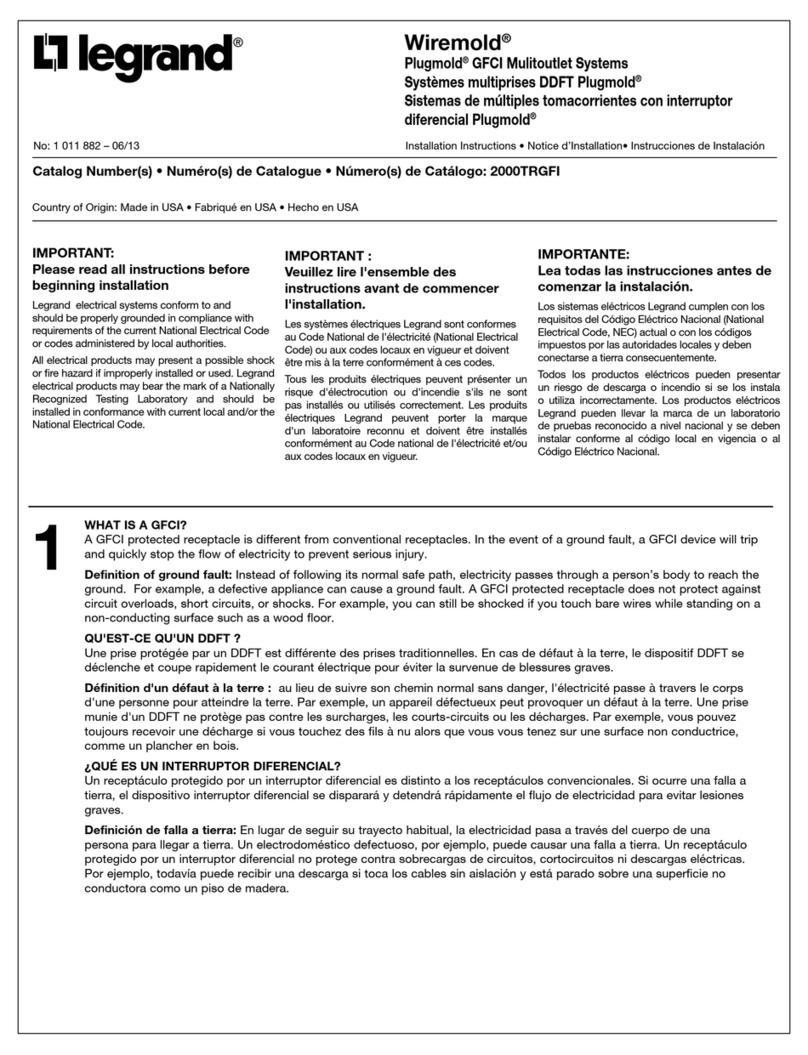

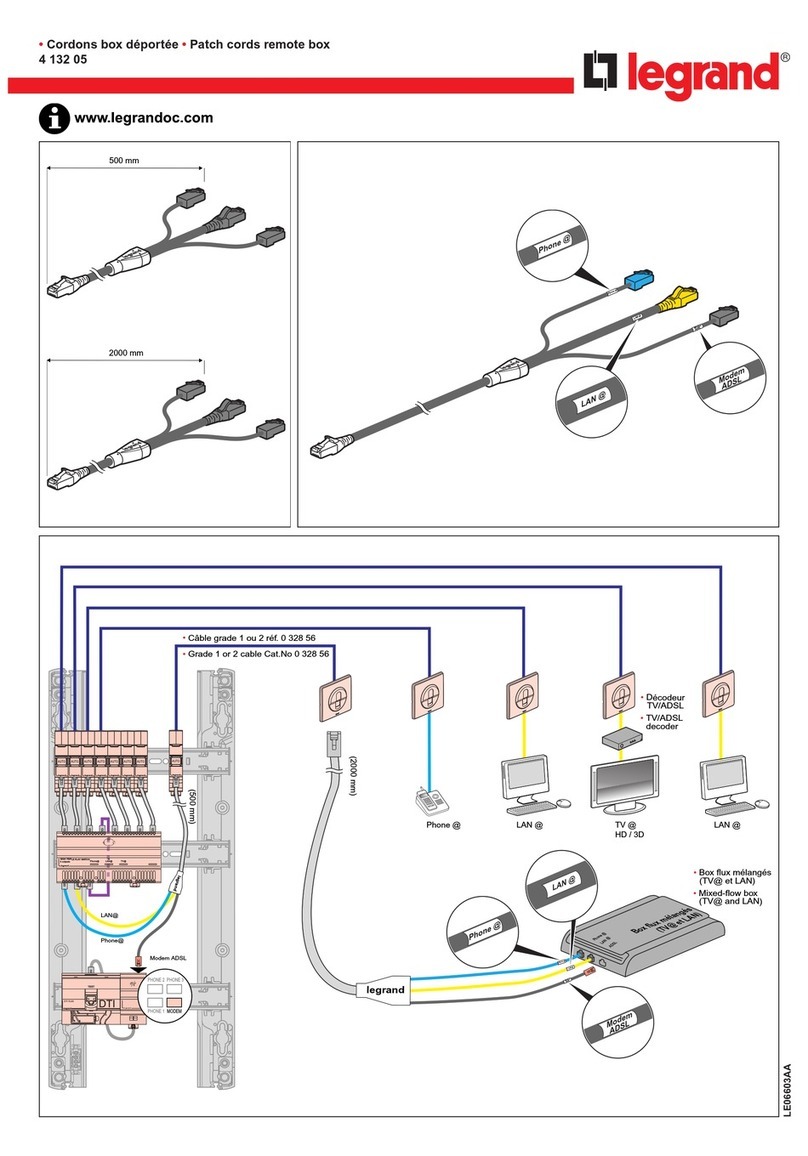

WIRE # OF WIRES PER # OF WIRES PER # OF WIRES PER # OF WIRES PER

WIRE SIZE O.D. CROSS-SECTIONAL OUTER CHANNEL OUTER CHANNEL OUTER CHANNEL INNER CHANNEL

THHN/THWN Inches [mm] AREA (40% FILL) w/OFR1 (40% FILL)** w/OFR9 (40% FILL) (40% FILL)

14 AWG 0.111 [2.8] 0.010 18 13 10 19

12 AWG 0.130 [3.3] 0.013 13 10 7 14

10 AWG 0.164 [4.2] 0.021 8329

8 AWG 0.216 [5.5] 0.037 4435

CABLE

WIRE

# OF CABLES PER # OF CABLES PER # OF CABLES PER # OF CABLES PER

O.D. (Approx Dia.)

CROSS-SECTIONAL OUTER CHANNEL OUTER CHANNEL OUTER CHANNEL INNER CHANNEL

TYPE CABLE/WIRE SIZE Inches [mm] AREA

(40% FILL) w/OFR1 (40% FILL)** w/OFR9 (40% FILL) (40% FILL)

UNSHIELDED

4-Pair, 24 AWG, Cat 3 0.190 [4.8] 0.028 6436

TWISTED PAIR

4-Pair, 24 AWG, Cat 5e 0.210 [5.3] 0.035 5325

4-Pair, 24 AWG, Cat 6 0.250 [6.4] 0.049 3223

4-Pair, 24 AWG, Cat 6a 0.354 [9.0] 0.098 1112

COAXIAL RG6/U 0.270 [6.9] 0.057 32 1 3

FIBER ZipCord 0.118 x 0.236 [3 x 6] 0.025 75 3 7

Round 4-Strand Fiber 0.187 [4.7] 0.027 64 3 6

Round 6-Strand Fiber 0.256 [6.5] 0.051 32 1 3

OFR Series Overfloor Raceway Wire Fill Capacities for Communications

OFR Series Overfloor Raceway Wire Fill Capacities for Power*

* For additional information refer to Technical Section of Wiremold Product Guide.

** Includes OFR11, OFR48-2, OFR48-4, OFR89-2400, ORF89-4000, OFR89-DS4000 and OFR89-VIS.