Table of content

Page 3 of 31

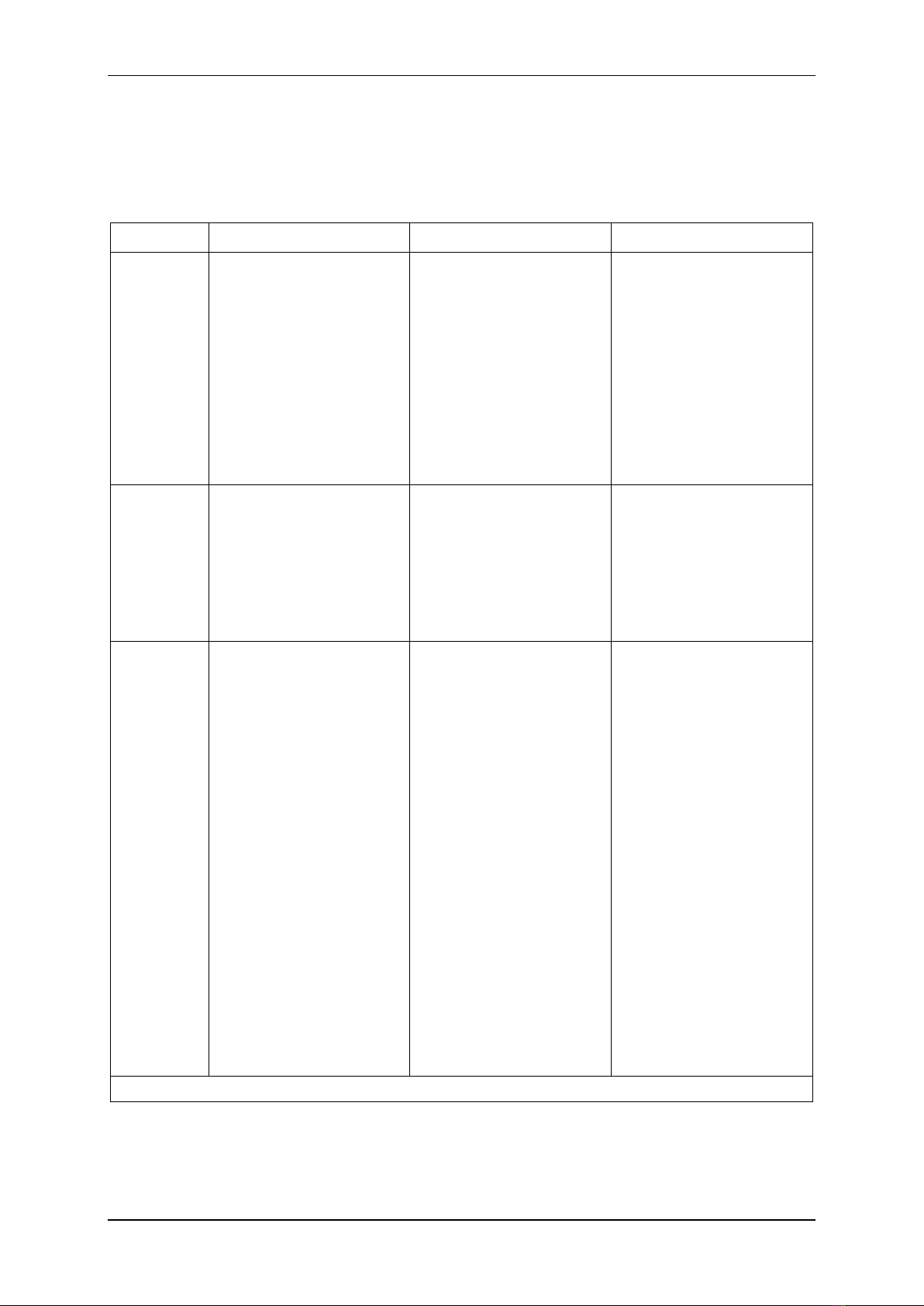

Table of content

1Introduction .............................................................................................................4

2Technical data ..........................................................................................................5

2.1 Overview ..........................................................................................................5

2.2 Font - Font height – Font width – Stroke distance – Speed ......................................6

3Features and applications ...........................................................................................7

3.1 Overview about features and applications ..............................................................7

3.2 Printing speed and the quality of printouts .............................................................8

3.3 Print samples ...................................................................................................11

3.3.1 Print samples RAPID Wire .........................................................................11

3.3.2 Print samples: RAPID Highspeed in comparison with RAPID Universal..............11

3.3.3 Print samples: RAPID Universal in comparison with JET3up – 2D codes ..........12

3.3.4 Print sample: RAPID Universal with 70000-00031 ink ...................................12

3.3.5 Print sample: RAPID Wire and Rapid Highspeed cabel printouts.......................13

4Available inks .........................................................................................................14

4.1 Different ink ranges for different printers .............................................................14

5RAPID Wire and Highspeed: The print head ventilation .................................................15

5.1 Basics about the functionality ............................................................................15

5.2 Technical details ..............................................................................................16

6Information about encoders ......................................................................................17

6.1 Basics.............................................................................................................17

6.2 The resolution and the output frequency of the encoder.........................................17

6.3 The specifications of the encoder input of the printer ............................................18

6.4 Recommendations regarding the encoder / Printer combination for high-speed

applications ...............................................................................................................19

6.5 Example for an encoder / printer combination .......................................................19

7Appendix ...............................................................................................................20

7.1 Hydraulic settings and printout parameters...........................................................20

7.1.1 Ink selection............................................................................................20

7.1.2 Print modes.............................................................................................22

7.1.2.1 Available print modes for the RAPID Universal ............................................22

7.1.2.2 Available print modes for the Rapid Highspeed............................................23

7.1.2.3 Available print modes for the Rapid Wire....................................................24

7.2 Print head adjustment: RAPID Wire and Highspeed ................................................25

7.2.1 Adjustment of the ink jet...........................................................................25

7.2.2 Adjustment of the drop production unit .......................................................28

7.2.3 Adjusting the distance between ink jet and ink drop voltage detector ..............31