Getting started/Operating principles

- 9 -

4. Getting started / Operating principles

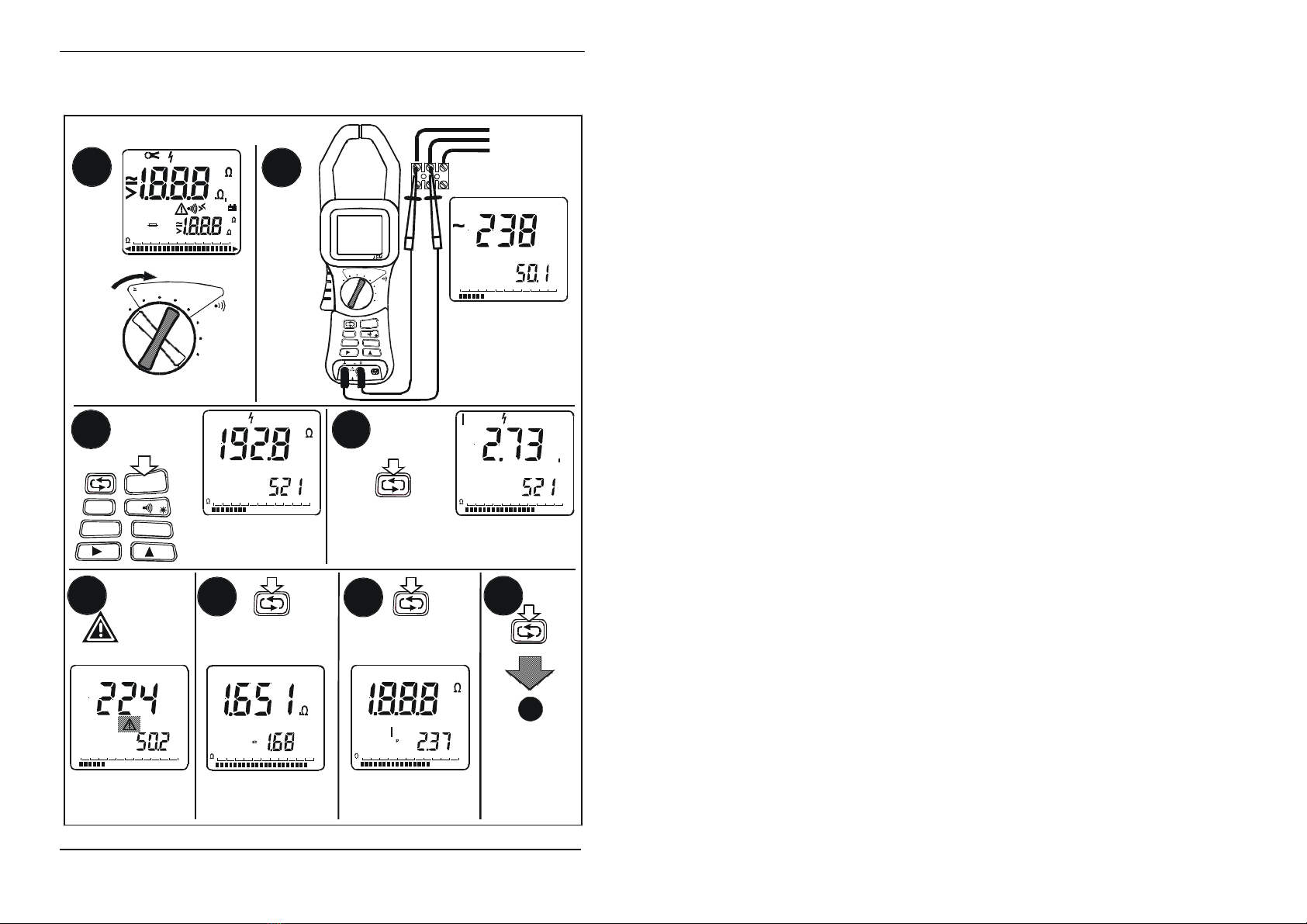

Examine the instrument carefully, familiarizing yourself with the layout of the input

terminals, rotary switch, pushbuttons and display. Notice the WARNING information

and summary of power-on options.

If you have used a multimeter and a current clamp before, simply examining your

meter will probably give you a good idea how to use it. The following procedure is an

overview of how to take basic measurements.

Two principal functions exist depending on the selected rotary switch position:

Continuous running measurement functions as volts, amps or standard

resistance/continuity tests and insulation tests, where the measurement has to be

started with the button. The test voltage depends on the rotary switch

position ranging from 100V up to 1000V. The functionality of the button

depends on the selected mode. Start can either start a measurement in the

insulation test or for the continuous mode functions (V, A, ,Ώ) it enables the

HOLD mode, where the actual displayed values in the LCD-display is frozen. In

insulation test after pressing more than 10 s instrument enters continuous

mode until is pressed again.

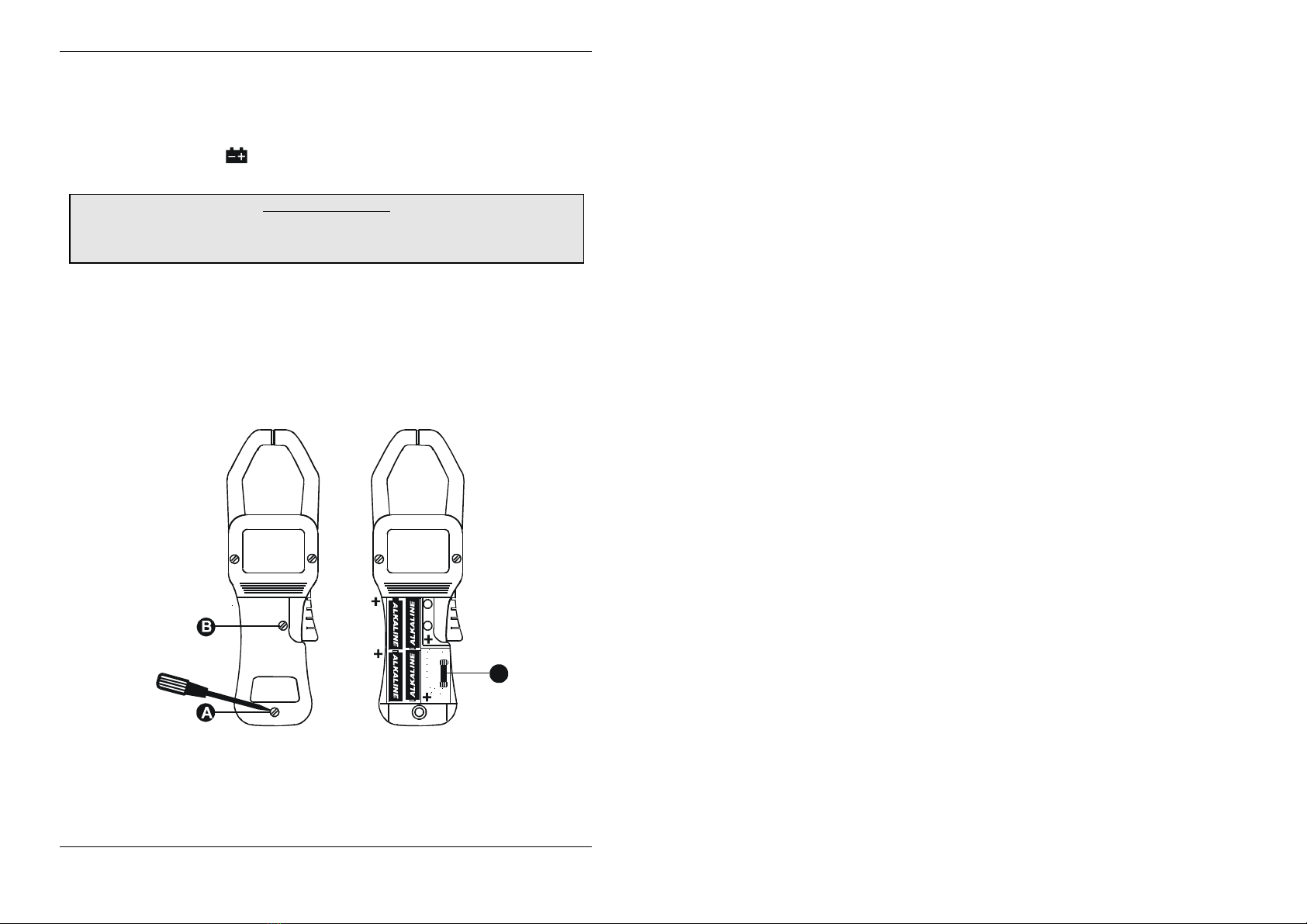

1. Insert the test leads in the appropriate input terminals COM and V Ώ

2. To turn the instrument on and select a function, turn the rotary switch from OFF to

the appropriate switch position. All segments on the liquid-crystal display (LCD)

will turn on for 3 seconds, then the meter is ready for normal operation.

The button switches between different screens displaying more data about

the measurement being made. For example, switching between limit or

frequency display and the different AC signal parts like RMS, TRMS.

3. To select an additional operation, press the appropriate pushbuttons underneath

the rotary switch as described in the items below.

• In the resistance measurement function the button enables the continuity

function. That means the continuity symbol in the LCD-display is activated and

the buzzer is also activated if the continuity limit is exceeded. The limit value

(trigger) can be set between 0.2Ωand 50Ωand defaults to 2Ω.

• For more advanced functions see section 6 of this manual

4. To take a measurement, use the test lead probes to make the proper contacts.

Remember, insert the instrument in the circuit in parallel for insulation, voltage

and resistance and use the clamp for current measurements. Read the

measurement on the display. If you did not manually fix the highest range (by

using the button while power on), the range that provides the best resolution

is automatically selected.