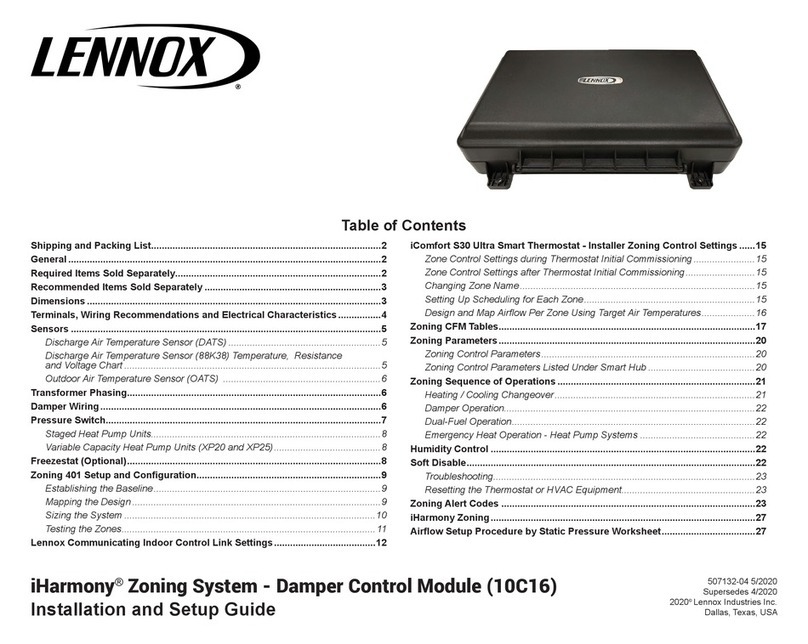

6

Air Temperature Sensor Connections

Refer to “Figure 1. Terminals and LEDs” on page 3 for various

terminal locations.

Table 4. Outdoor Air and Discharge Air Sensors

Label Function / Description

Outdoor Air

Sensor

Show ambient temperatures (optional if weather feed is acceptable or

outdoor unit is a communicating unit; use X2658 Outdoor Sensor - 2

terminals).

NOTE: Wiring distance between the EIM and the outdoor temperature

sensor can not exceed 150 feet (45 meters) when wired with

minimum 22AWG (Recommend) 18AWG dedicated two-

conductor thermostat cable.

Discharge Air

Sensor

Optional for diagnostics of indoor air; use 88K38 Discharge Air Sensor -

2 terminals.

Lennox Communicating Terminal Connections and Wiring

Recommendations

Table 5. Communicating Terminals

Label Function / Description Thermostat Wiring

R 24VAC communication power Input 18AWG unshielded

i+ Communication high – data line 18 - 22AWG shielded

(recommended)

i- Communication low – data line

C24VAC communication common

power Input 18AWG unshielded

IMPORTANT

Use 18AWG unshielded thermostat cable (eld-provided) for power

terminals (R and C) and all non-communicating terminals. Highly

recommend using 18 - 22AWG shielded thermostat cable for

communications terminals ( i+ and i-) which will help eliminate any noise

interference.

Dual-Fuel Terminal Connections

Table 6. Dual-Fuel Terminals

Label Description Function

DFTS

Pre-coil discharge

air temperature (2

terminals)

The pre-coil discharge air sensor should be

installed downstream of the gas heat exchanger

and before the in door coil when a heat pump is

used and defrost tempering is required.

It must be placed in free airow, where other

accessories (such as humidiers, UV lights, etc.)

will not interfere with its accuracy. Wiring distance

between the EIM and the discharge air sensor

should not exceed 10 feet when using 18AWG

thermostat wire.

W1-DEF Defrost signal input

This input is used in systems with non-

communicating heat pumps for defrost indication.

The input provides a nominal load of 50 mA, 24

VAC.

0

Heat Pump Reversing

Valve (Powered for

cooling)

In systems with communicating IFC, the EIM (HP)

O output is connected to a non-communicating

heat pump compatible with O signal for reversing

valve operation. A 24VAC signal is generated on

O for cooling operation, while the terminal is open

for heating operation.

B

Heat Pump Reserving

Valve

(Powered for

heating)

In systems with communicating IFC, the EIM (HP)

B output is connected to a non-communicating

heat pump compatible with B signal for reversing

valve operation. A 24VAC signal is generated on

B for heat pump operation, while the terminal is

open for cooling operation.

Conventional Terminal Connections and Wiring Requirement

Table 7. Conventional Terminals

Label Description Function

18AWG unshielded thermostat cable (eld-provided) for

all non-communicating connections

W1 1st - stage heat output (1st stage gas heat output when congured as IFC

and 1st stage electric heat output when congured as AHC.

W2 2nd - stage heat output (2nd stage gas heat output when congured as

IFC and 2nd stage electric heat output when congured as AHC.

W3 3rd - stage heat output (3nd stage electric heat output when congured as

AHC)