Page 8

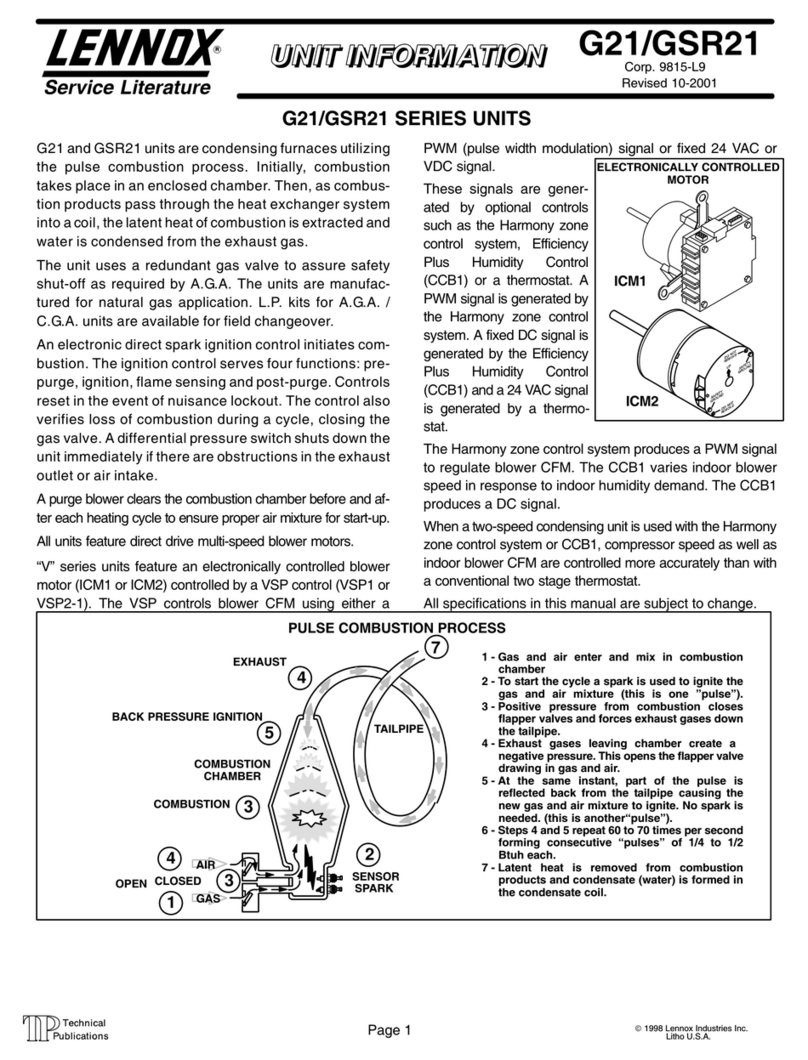

Scroll Compressor Operations

The B1 scroll compressor design is simple, efficient and

requires few moving parts. A cutaway diagram of the scroll

compressor is illustrated in Figure 7. The scrolls are

located in the top of the compressor can and the motor is

located just below. The oil level is immediately below the

motor.

SCROLL FORM

Figure 6. Scroll Form

DISCHARGE

SUCTION

Figure 7. Scroll Compressor

WARNING

This product and/or the indoor unit it is matched with may contain

fiberglass wool.

Disturbing the insulation during installation, maintenance, or repair will

expose you to fiberglass wool dust. Breathing this may cause lung

cancer. (Fiberglass wool is known to the State of California to cause

cancer.)

Fiberglass wool may also cause respiratory, skin, and eye irritation.

To reduce exposure to this substance or for further information, consult

material safety data sheets available from address shown below, or

contact your supervisor.

Lennox Industries Inc.

P.O. Box 799900

Dallas, TX 75379−9900

General Information

These instructions are intended as a general guide and do

not supersede local codes in any way. Consult authorities

who have jurisdiction before installation.

Operating Gauge Set and Service Valves

These instructions are intended as a general guide and do

not supersede local codes in any way. Consult authorities

who have jurisdiction before installation.

TORQUE REQUIREMENTS

When servicing or repairing heating, ventilating, and air

conditioning components, ensure the fasteners are

appropriately tightened. Table 1 lists torque values for

fasteners.

IMPORTANT

Only use Allen wrenches of sufficient hardness (50Rc − Rockwell

Harness Scale minimum). Fully insert the wrench into the valve stem

recess.

Service valve stems are factory−torqued (from 9 ft−lbs for small valves,

to 25 ft−lbs for large valves) to prevent refrigerant loss during shipping

and handling. Using an Allen wrench rated at less than 50Rc risks

roundingor breaking off the wrench, or stripping the valve stem recess.

See the Lennox Service and Application Notes #C−08−1 for further

details and information.

IMPORTANT

To prevent stripping of the various caps used, the appropriately sized

wrench should be used and fitted snugly over the cap before tightening.

When servicing or repairing HVAC components, ensure

the fasteners are appropriately tightened. Table 1 provides

torque values for fasteners.

Table 1. Torque Requirements

Parts Recommended Torque

Service valve cap 8 ft.− lb. 11 NM

Sheet metal screws 16 in.− lb. 2 NM

Machine screws #10 28 in.− lb. 3 NM

Compressor bolts 90 in.− lb. 10 NM

Gauge port seal cap 8 ft.− lb. 11 NM

USING MANIFOLD GAUGE SET

When checking the system charge, only use a manifold

gauge set that features low loss anti−blow back fittings.

Manifold gauge set used with HFC−410A refrigerant

systems must be capable of handling the higher system

operating pressures. The gauges should be rated for use

with pressures of 0 − 800 psig on the high side and a low

side of 30" vacuum to 250 psig with dampened speed to

500 psi. Gauge hoses must be rated for use at up to 800

psig of pressure with a 4000 psig burst rating.

OPERATING SERVICE VALVES

The liquid and vapor line service valves are used for

removing refrigerant, flushing, leak testing, evacuating,

checking charge and charging.

Each valve is equipped with a service port which has a

factory−installed valve stem. Figure 8 provides information

on how to access and operating both angle and ball service

valves.