Page 9

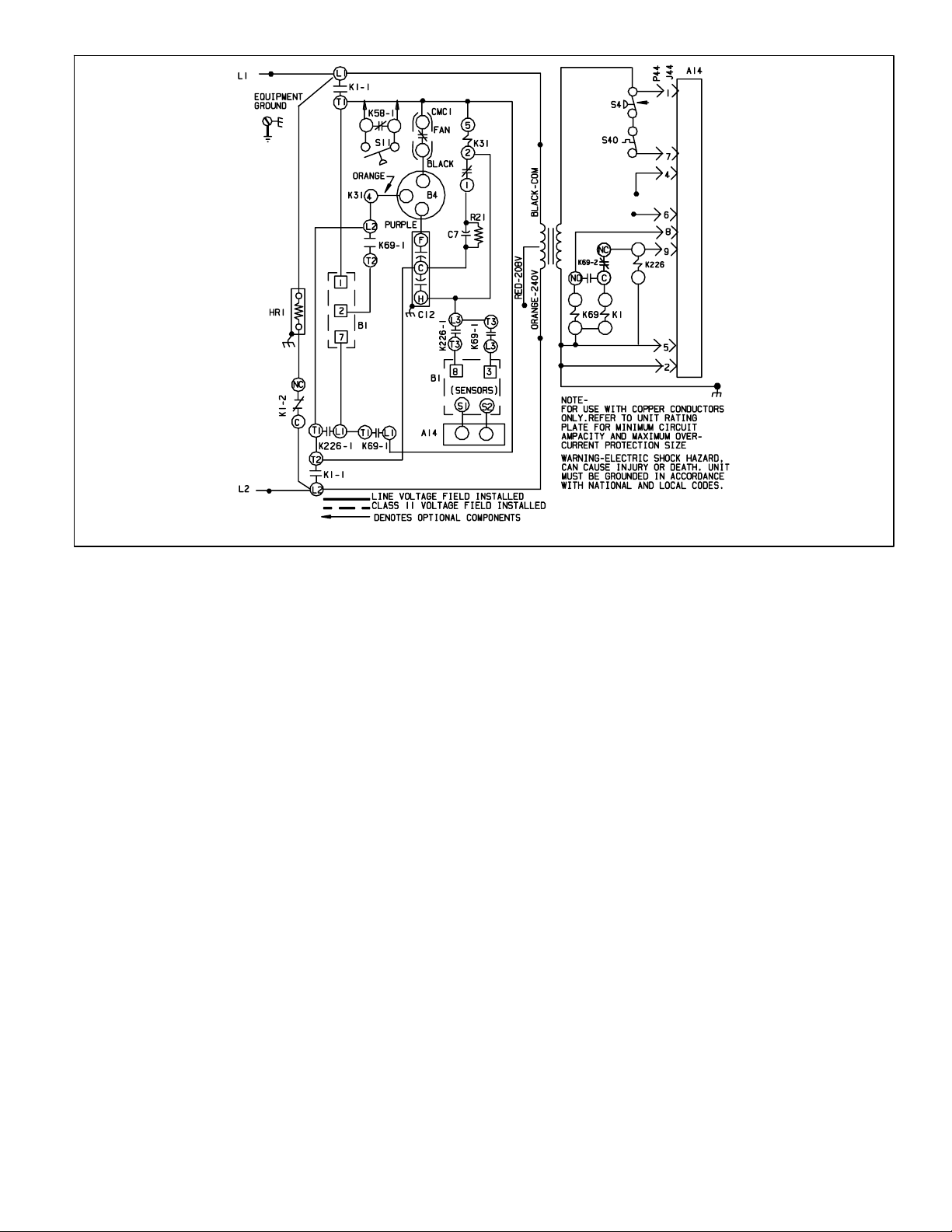

Single−Phase Compressor Operation

Checklist

LOW SPEED

1. First−Stage Demand: If all safety circuits check out,

TSC (A14) energizes JP44−9.

2. Contactor K1 and K226 are energized. K1−2 contacts

open to de−energize the crankcase heater. All other K1

contacts close to start outdoor fan and to begin

compressor low speed operation. K226−1 contacts

close to begin compressor low speed operation.

3. Compressor (B1) terminal 1 and the outdoor fan circuit

are energized by K1 contacts L1−T1. Compressor

terminal 7 is energized by contacts K1 terminals L2−T2

and K226 terminals T1−L1. Compressor terminal 8

(low speed start winding) is energized through

contactor K1 terminals L2−T2, through the run and

start capacitors, and to contactor K226−1 terminals

L3−T3.

4. As the compressor nears proper speed, potential relay

K31 energizes and K31 terminals 1–2 open.

HIGH SPEED

1. Second Stage Demand: If all safety circuits check out,

TSC (A14) energizes JP44−8.

2. Contactor K69 energizes and K69−2 auxiliary contacts

close to energize contactor K1 coils and de−energize

K226 contactor coil. K1−2 contacts open to

de−energize the crankcase heater. K1 contacts L1−T1,

L2−T2 and L3−T3 close, while K226 contacts L1−T1

and L3−T3 open.

3. Compressor (B1) terminal 3 (high speed start winding)

is energized by contactor K1 terminal L2−T2, through

the run and start capacitors and through contactor K69

terminals L3−T3. Compressor terminal 2 is energized

by contactor K1 terminal L2−T2. Compressor terminal

7 is energized by K1 contactor terminals L1−T1

through contactor K69 terminals L1−T1.

4. As the compressor nears proper speed, potential relay

K31 energizes and K31 terminals 1–2 open.

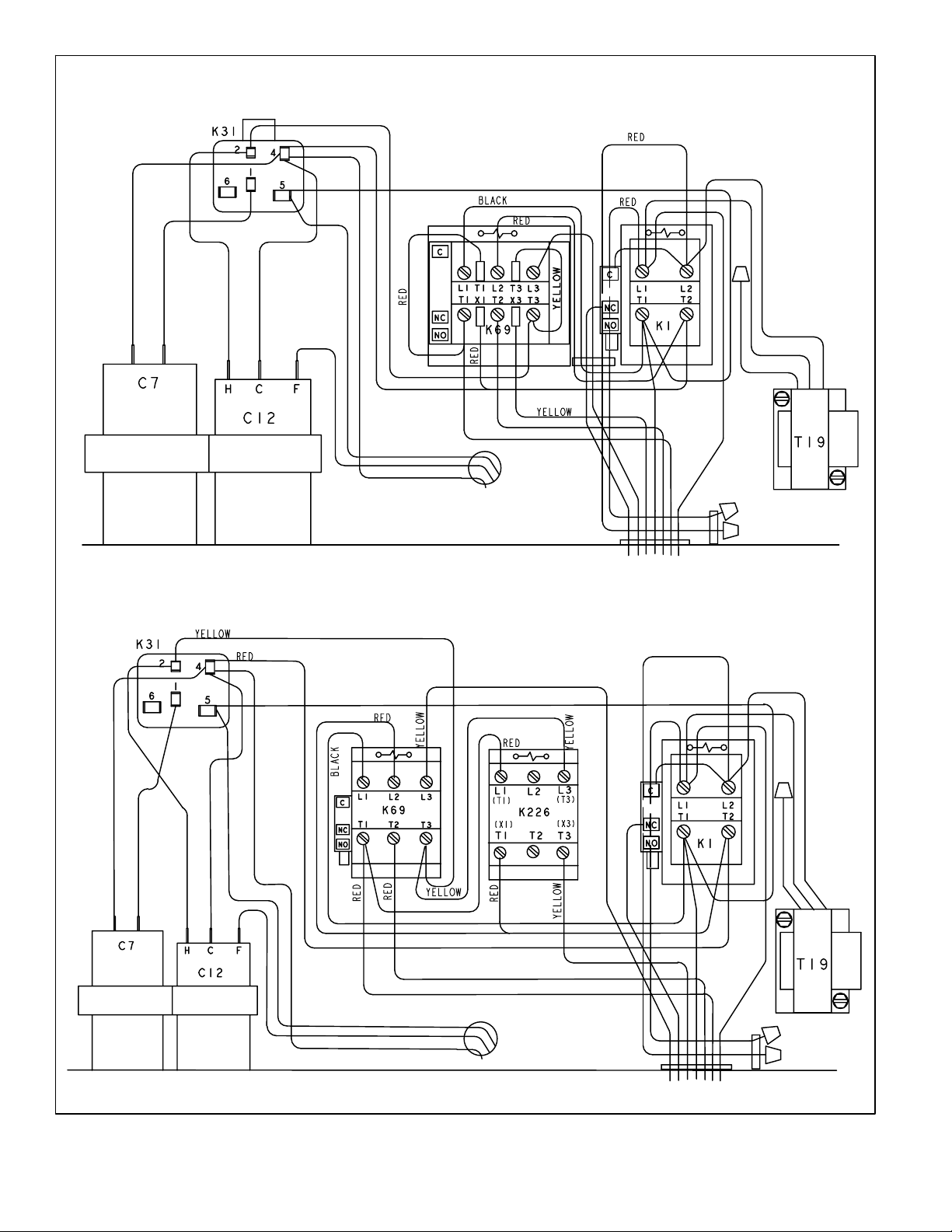

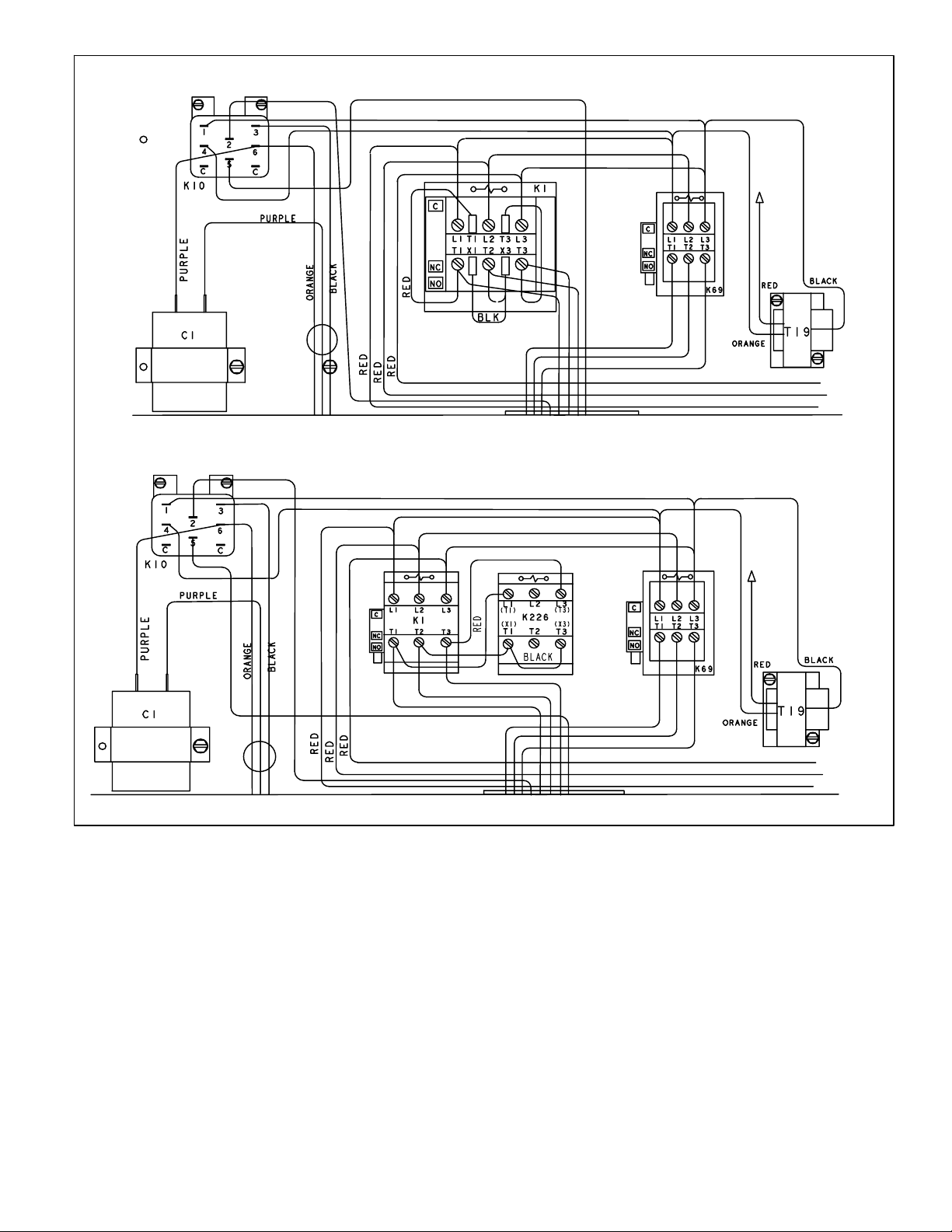

Three−Phase Compressor Operation

Checklist

LOW SPEED

1. First Stage Demand: Low speed (Y1) room thermostat

demand energizes outdoor fan relay and JP44−6.

K10−1 switches to energize the outdoor fan and

de−energize the compressor crankcase heater.

Outdoor fan begins operating immediately.

2. If all safety circuits check out, TSC (A14) energizes

JP44−9. Contactor K1 coil is energized through K69−2

NC end switch contacts.

3. After appropriate time delay, K1 contacts close to

cycle compressor onto low speed. K226 contacts

remain open to disconnect the high speed wiring

circuitry.

4. Compressor (B1) terminal 1 is energized by K1

terminal L1−T1. Compressor terminal 2 is energized by

K1 terminals L2−T2. Compressor terminal 3 is

energized through K1 terminal L3−T3.

HIGH SPEED

1. Second Stage Demand: High speed (Y2) room

thermostat demand energizes JP44−4.

2. If all safety circuits check out, TSC (A14) energizes

JP44−8.

3. Contactors K69 and K226 energize through K1−2 end

switch contacts. K69 and K226 contactor coils close

for compressor high speed operation. Compressor

terminal 4 is energized by contactor K69 terminals

L1−T1. Compressor terminal 6 is energized by

contactor K69 terminals L2−T2. Compressor terminal

5 is energized by K69 contactor terminals L3−T3.

Compressor terminals 1, 2 and 3 are connected

through K226 contacts L1−T1 and L3−T3.