www.lerdge.com

8

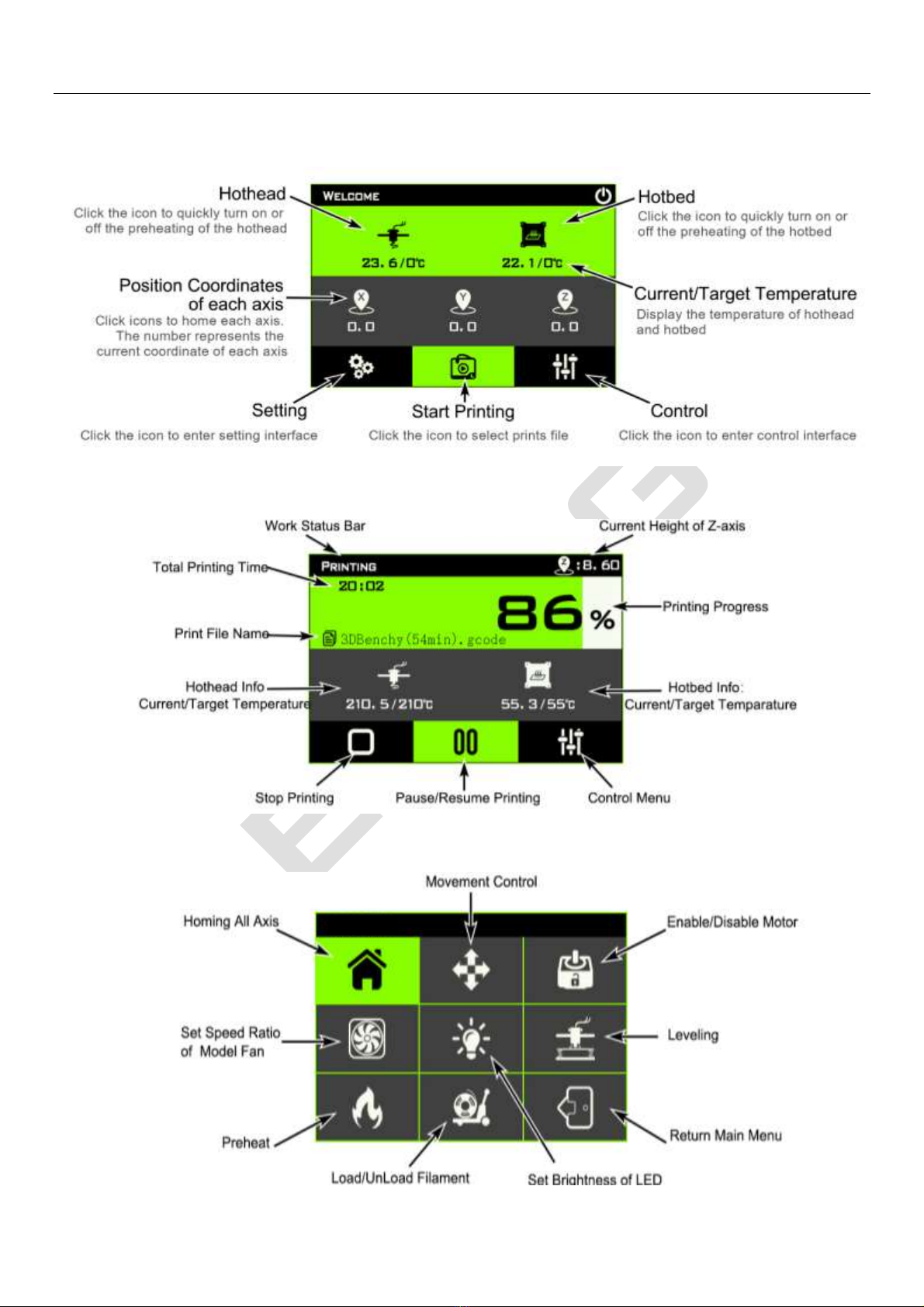

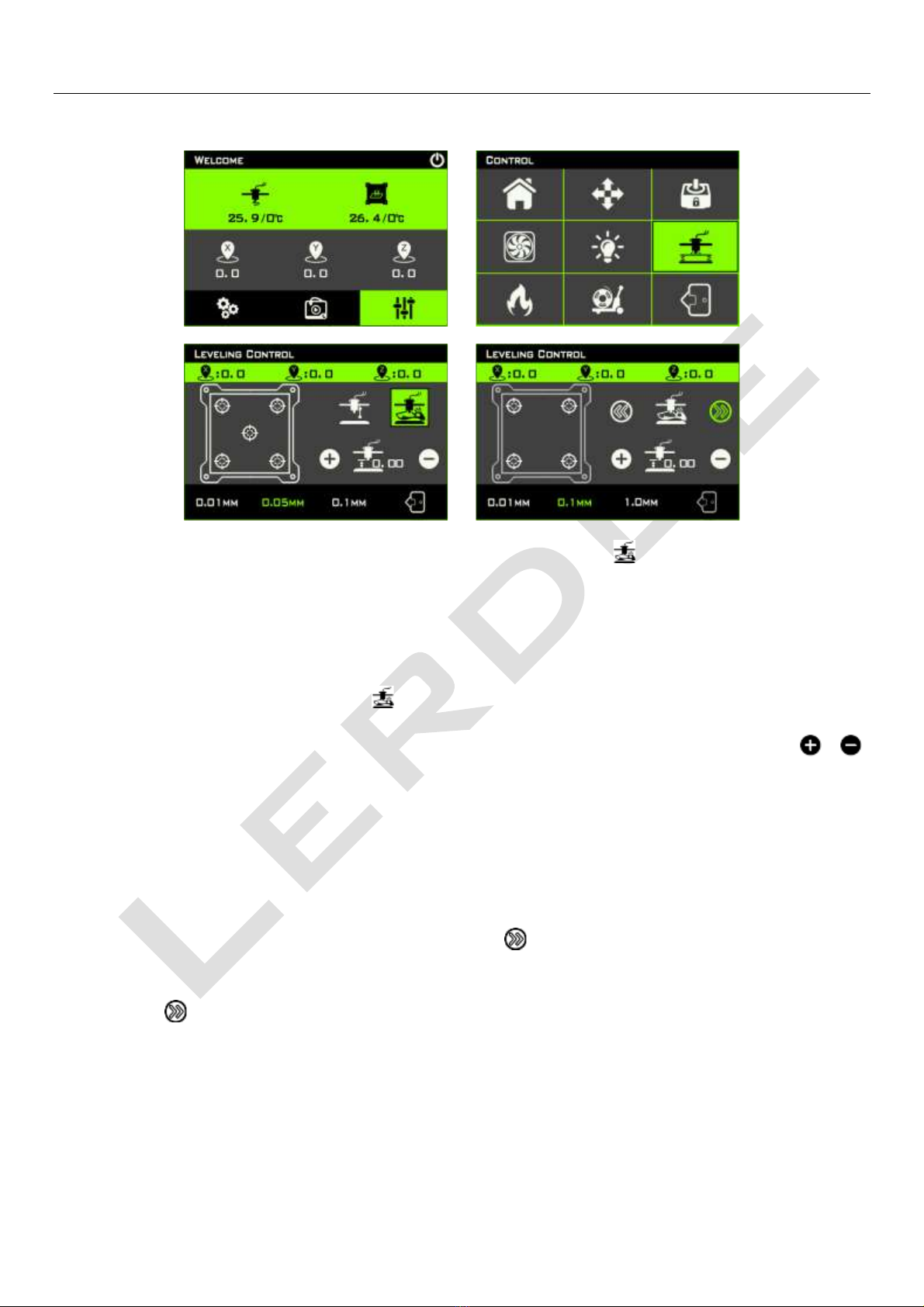

10.Check the leveling effect

In the leveling control interface, click the 5 “ ” icons in the hotbed frame on the left side of the

display, and the print head will move to the 5 positions corresponding to the actual hotbed in turn.

At this time, you can check the leveling effect of each position. The ideal effect should be that the

nozzle of the print head just touches the printing platform in five positions. In practice, it is normal if

there is a slight difference in a certain position. After all, it is a human judgment in the previous

leveling process.

In this case, you can adjust the Z-axis fine-tuning whose icon displays at the middle and lower

position on the right side of the display. Note: The adjustment at this time is overall adjustment of

the Z-axis, not a single point adjustment. The leveling needs to be re-executed if the difference

between the five points is large.

11.Preheating the hotend

Firstly, check the temperature measurement function of the hotend. In the main interface, the format

of the temperature value below the icons of the hotend is displayed as xxx/xxx°C, and the value in

front of “/” represents the current real-time temperature of the hotend.

Please check whether the real-time temperature of the hotend be close to the room temperature.

The value behind the “/” is the heating target temperature of the hotend. When it is displayed as 0,

it means that the hotend stop heating.

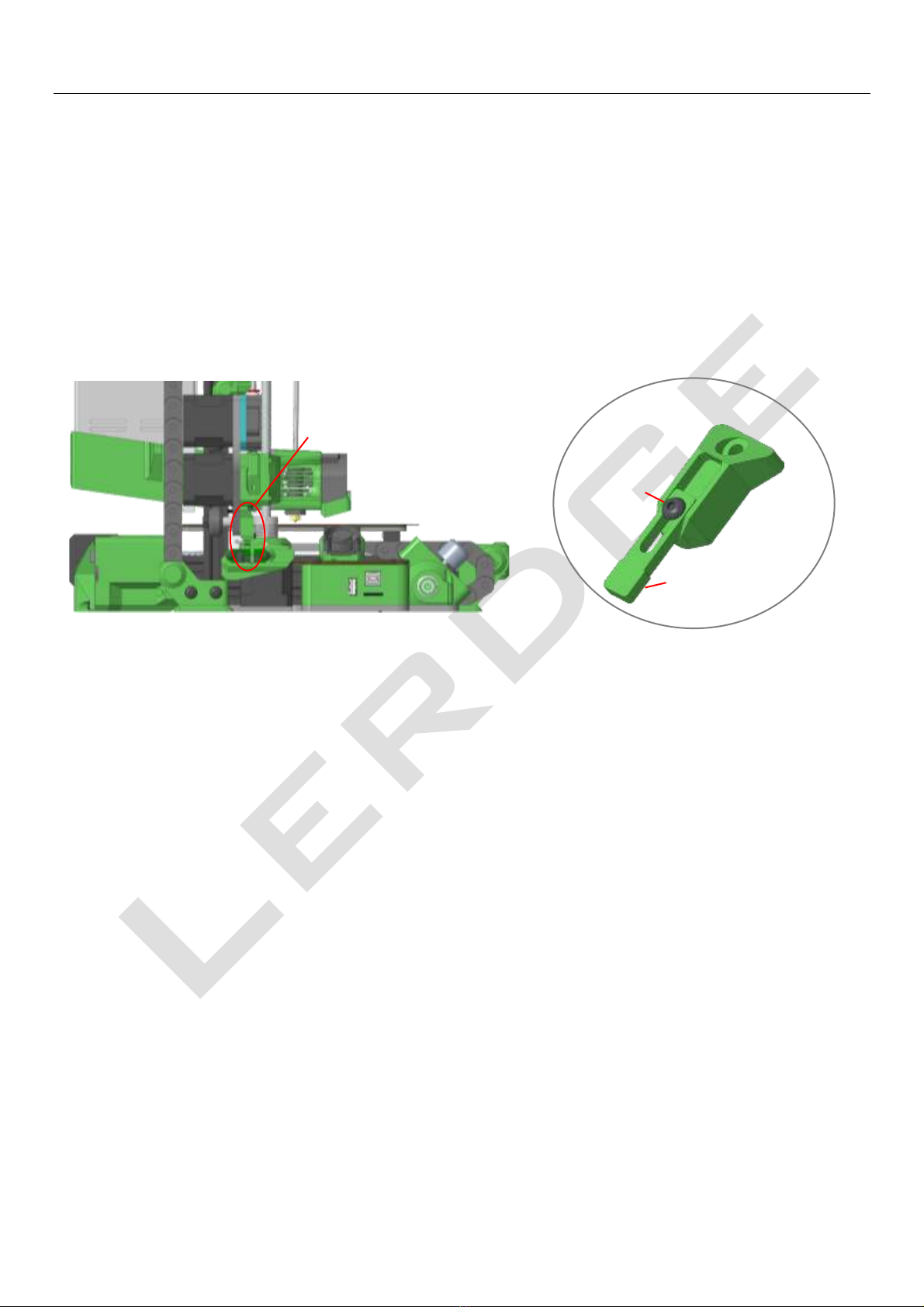

Secondly, lift the X-axis cantilever, at least ensure that the nozzle is at a distance of more than 5mm

from the printing platform, so that it is easy to observe the extrusion of the filament from the nozzle

or clean the nozzle. Then go back to the main interface, click the icon of the hothead and the hotbed,

and the target temperature under the icon of the hothead and the hotbed will be set. Then observe

whether the real-time temperature of the hotend starts to rise.