Table of contents

Leuze electronic MLC 520S 3

Table of contents

1 About this document ............................................................................................5

1.1 Used symbols and signal words ............................................................................................. 5

1.2 Checklists................................................................................................................................ 6

2 Safety .....................................................................................................................7

2.1 Intended use and foreseeable misuse.................................................................................... 7

2.1.1 Intended use........................................................................................................................7

2.1.2 Foreseeable misuse ............................................................................................................8

2.2 Necessary competencies........................................................................................................ 8

2.3 Responsibility for safety.......................................................................................................... 9

2.4 Disclaimer ............................................................................................................................... 9

3 Device description ..............................................................................................10

3.1 Device overview of the MLC family....................................................................................... 10

3.2 Connection technology ......................................................................................................... 10

3.3 Cascading ............................................................................................................................. 11

3.4 Display elements .................................................................................................................. 12

3.4.1 Operation indicators on the MLC520S transmitter/receiver .............................................12

4 Functions.............................................................................................................14

4.1 Start/restart interlock RES .................................................................................................... 14

4.2 EDM contactor monitoring .................................................................................................... 15

5 Applications ........................................................................................................16

5.1 Point of operation guarding................................................................................................... 16

6 Mounting..............................................................................................................17

6.1 Arrangement of transmitter and receiver .............................................................................. 17

6.1.1 Calculation of safety distanceS ........................................................................................17

6.1.2

Calculation of safety distance if protective fields act orthogonally to the approach direction.. 18

6.1.3 Minimum distance to reflective surfaces ...........................................................................21

6.1.4 Preventing mutual interference between adjacent devices ............................................... 22

6.2 Mounting the safety sensor................................................................................................... 23

6.2.1 Suitable mounting locations ..............................................................................................23

6.2.2 Mounting with O-shaped mounting brackets ..................................................................... 24

6.2.3 Mounting with C-shaped mounting brackets .....................................................................25

6.2.4 Mounting with L-shaped mounting brackets...................................................................... 27

6.2.5 Mounting with L- and C-shaped mounting brackets .......................................................... 29

6.3 Mounting accessories ........................................................................................................... 30

6.3.1 Deflecting mirror for multiple-side guarding.......................................................................30

6.3.2 Mounting cascading ..........................................................................................................30

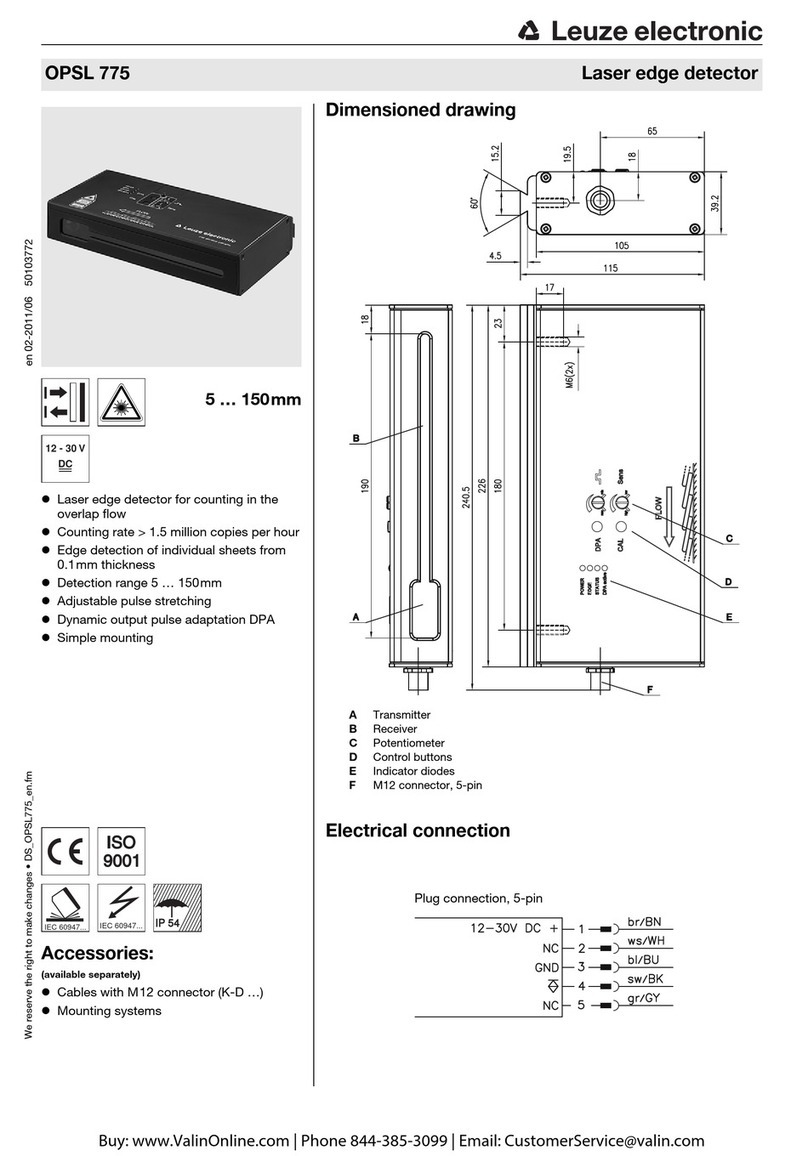

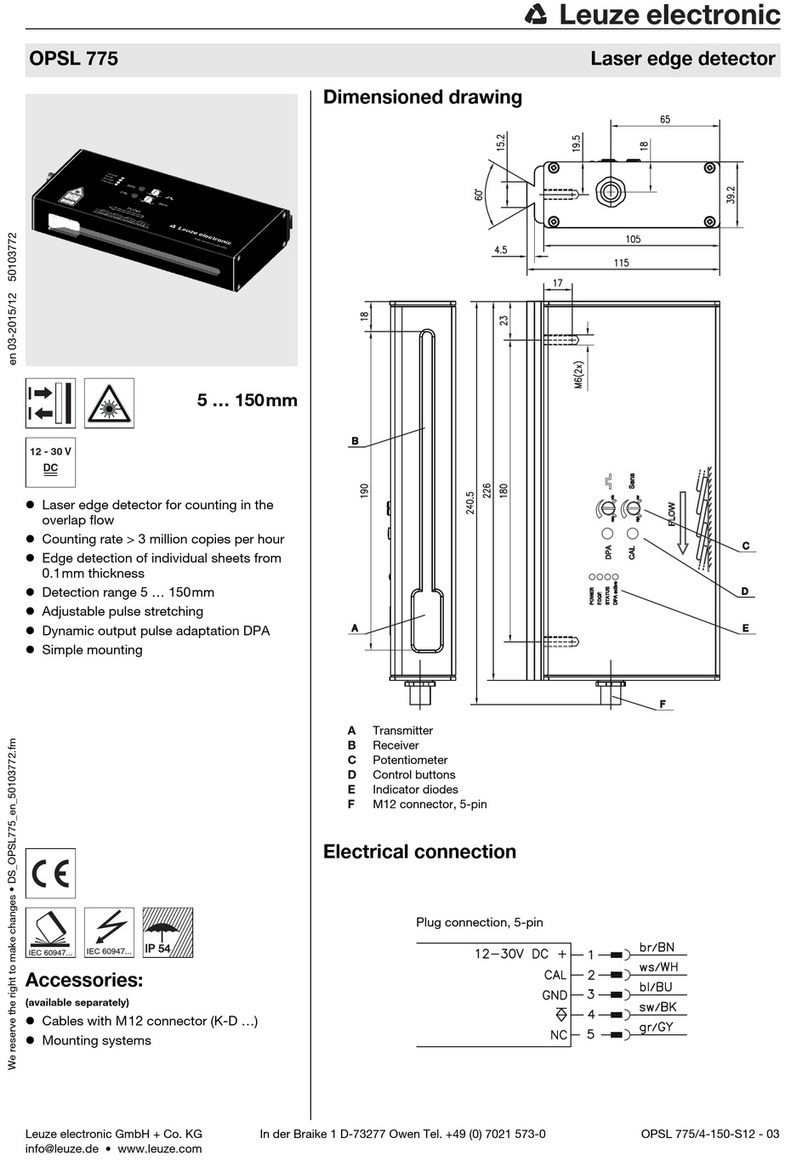

7 Electrical connection..........................................................................................33

7.1 Pin assignment transmitter and receiver .............................................................................. 33

7.1.1 MLC520S transmitter .......................................................................................................33

7.1.2 MLC520S receiver............................................................................................................34

8 Starting up the device ........................................................................................35

8.1 Switching on ......................................................................................................................... 35

8.2 Aligning the sensor ............................................................................................................... 35

8.3 Minimum distance for cascade system................................................................................. 37

8.4 Selection of RESTART mode and operation ........................................................................ 37

8.5 Unlocking start/restart interlock ............................................................................................ 39