Table of contents

Leuze electronic GmbH + Co. KG CMS 748i 3

Table of contents

1 About this document ............................................................................................5

2 Safety .....................................................................................................................6

2.1 Intended use ...........................................................................................................................6

2.2 Foreseeable misuse................................................................................................................7

2.3 Competent persons.................................................................................................................7

2.4 Disclaimer ...............................................................................................................................8

3 Device description ................................................................................................9

3.1 Device overview......................................................................................................................9

3.2 Evaluation unit ......................................................................................................................11

3.2.1 Connections.......................................................................................................................11

3.2.2 Indicators and operational controls....................................................................................12

4 Functions.............................................................................................................13

4.1 Operating principle................................................................................................................13

4.2 System resolution .................................................................................................................14

4.3 Object angle of rotation, object length and object width .......................................................15

4.4 Projections and deformations on the measurement object...................................................15

4.4.1 Function.............................................................................................................................15

4.4.2 Projection suppression ......................................................................................................18

4.4.3 Deformation detection .......................................................................................................20

4.5 Minimum distance between two measurement objects ........................................................21

4.6 Maximum conveyor speed ....................................................................................................21

5 Mounting..............................................................................................................23

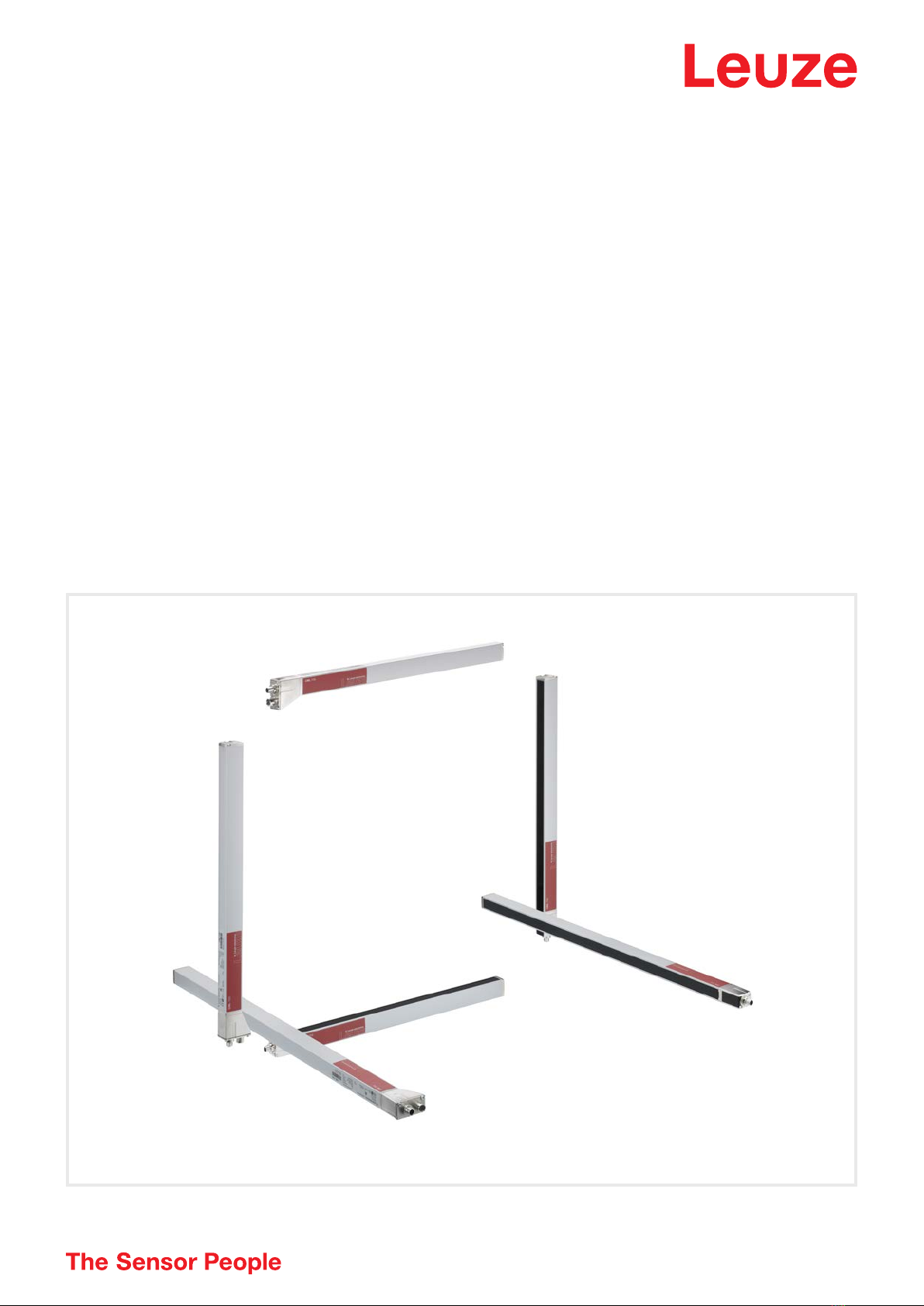

5.1 Installation with three light curtains .......................................................................................24

5.1.1 Mounting instructions.........................................................................................................24

5.1.2 Positioning for height measurement..................................................................................25

5.1.3 Positioning for width measurement ...................................................................................26

5.1.4 Positioning for length measurement..................................................................................27

5.2 Mounting the light curtain......................................................................................................27

5.2.1 Definition of directions of movement .................................................................................29

5.2.2 Fastening via sliding blocks...............................................................................................29

5.2.3 Fastening via BT-2P40 mounting clamp............................................................................29

5.2.4 Fastening of the length light curtain using BT-2SB10 mounting clamps ...........................30

5.3 Air wipe unit ..........................................................................................................................31

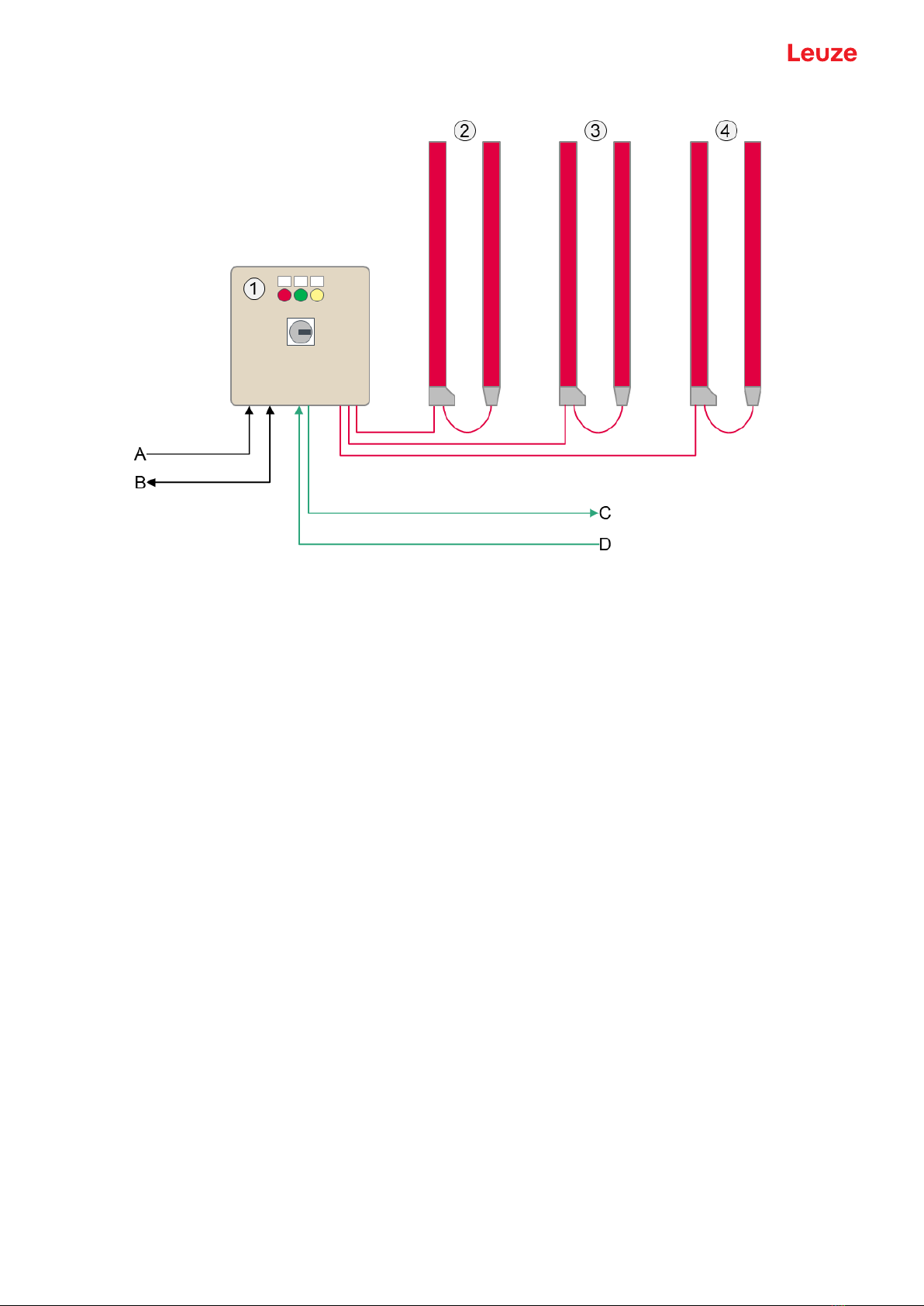

6 Electrical connection..........................................................................................32

6.1 Connection overview.............................................................................................................32

6.2 Connecting the power supply within the UL scope of application .........................................33

6.3 Connecting the power supply outside of the UL scope of application...................................33

6.4 Connecting light curtains.......................................................................................................35

6.5 Connecting the air wipe unit..................................................................................................37

6.6 Connecting PROFINET.........................................................................................................38

6.7 EMC-compliant installation ...................................................................................................39

6.7.1 Grounding the evaluation unit ...........................................................................................39

6.7.2 Grounding the light curtain housing...................................................................................40

6.7.3 Shielding and line lengths..................................................................................................41