Table of contents

Leuze electronic GmbH + Co. KG BPS 307i 4

6 Mounting..............................................................................................................33

6.1 Mounting barcode tape ........................................................................................................ 33

6.1.1 Installation and application remarks ..................................................................................33

6.1.2 Cutting barcode tapes ......................................................................................................34

6.1.3 Mounting the BCB .............................................................................................................35

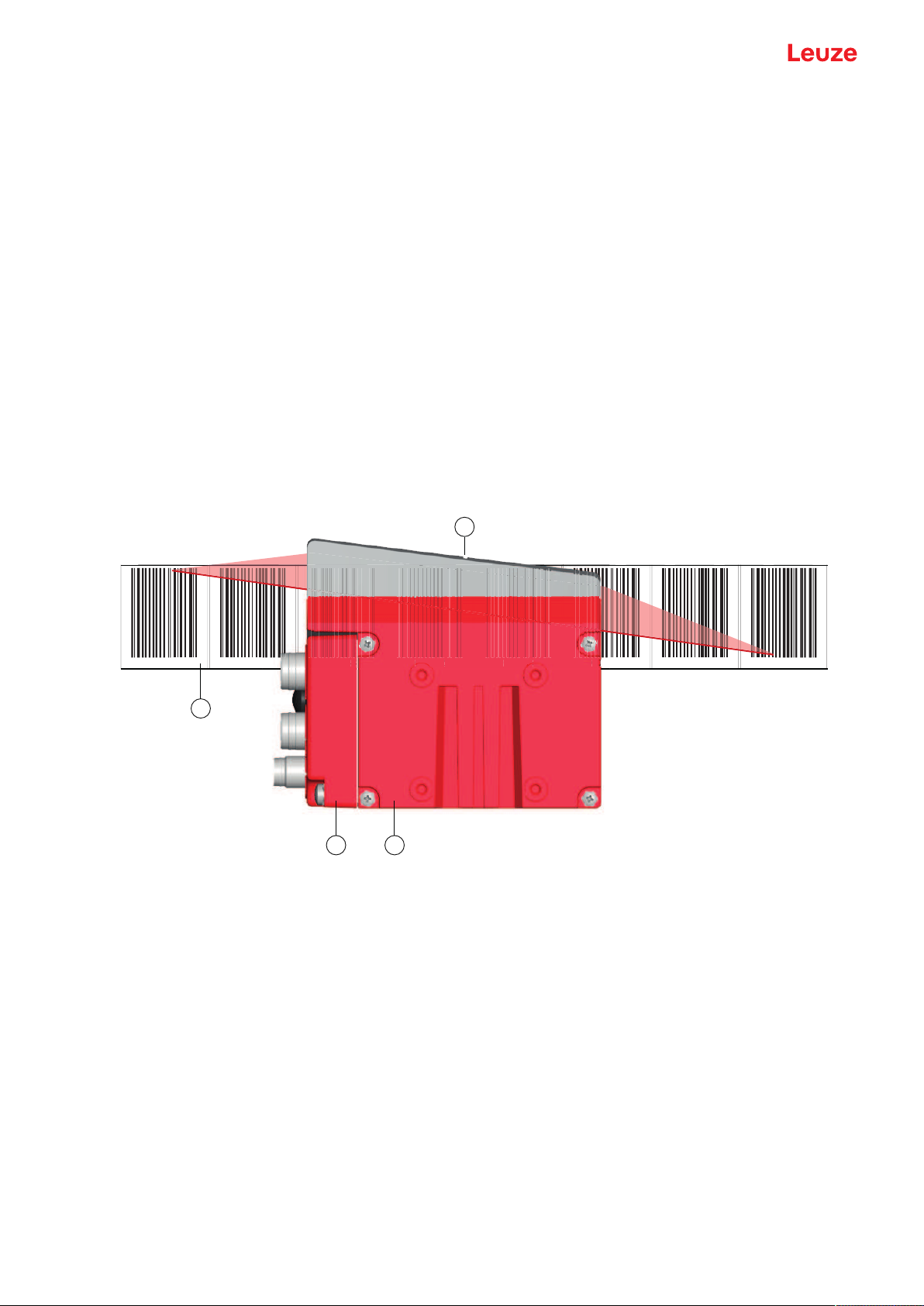

6.2 Mounting the barcode positioning system ........................................................................... 38

6.2.1 Mounting instructions ........................................................................................................39

6.2.2 Orientation of the BPS to the bar code tape......................................................................40

6.2.3 Mounting with the BTU 0300M-W mounting device ..........................................................40

6.2.4 Mounting with the BT300W mounting bracket.................................................................41

6.2.5 Mounting with BT56 mounting device ..............................................................................41

6.2.6 Mounting with BT300-1 mounting device .........................................................................42

6.2.7 Mounting with M4 fastening screws ..................................................................................42

7 Electrical connection..........................................................................................43

7.1 External parameter memory in the connection hood ............................................................ 43

7.2 MS307 connection hood with connectors ............................................................................ 44

7.3 MK307 connection hood with spring-cage terminals ........................................................... 44

7.4 KB307 connection hood with cable...................................................................................... 45

7.5 Pin assignment ..................................................................................................................... 46

7.5.1 PWR/SWIN/OUT (Power and switching input/output).................................................... 46

7.5.2 SSI (HOST/BUSIN) ........................................................................................................48

7.5.3 SSI connection cable.........................................................................................................49

7.5.4 Service USB ......................................................................................................................49

7.6 Cable lengths and shielding.................................................................................................. 50

8 Starting up the device – Basic configuration...................................................51

8.1 Configuring the SSI interface................................................................................................ 51

8.1.1 Principal functionality of the SSI interface .........................................................................51

8.1.2 Setting the configuration of the SSI interface ....................................................................53

8.2 Configuring the switching inputs/outputs .............................................................................. 53

8.3 Configuring the resolution for the position value................................................................... 53

8.4 Configuring speed monitoring with switching output............................................................. 53

8.5 Setting tape selection via the webConfig tool ....................................................................... 54

8.6 Configuration via the switches of the connection hood......................................................... 54

8.7 Setting configuration parameters to factory settings............................................................. 56

8.8 Key factory settings of the BPS ............................................................................................ 57

9 Starting up the device – webConfig tool ..........................................................58

9.1 Installing software ................................................................................................................. 58

9.1.1 System requirements ........................................................................................................58

9.1.2 Install USB driver...............................................................................................................58

9.2 Start webConfig tool ............................................................................................................. 59

9.3 Short description of the webConfigtool ................................................................................ 60

9.3.1 Overview ...........................................................................................................................60

9.3.2 PROCESS function ...........................................................................................................61

9.3.3 ALIGNMENT function........................................................................................................61

9.3.4 CONFIGURATION function...............................................................................................62

9.3.5 DIAGNOSIS function.........................................................................................................68

9.3.6 MAINTENANCE function...................................................................................................68