3-Way or More Applications (Multi-Location)

Decora®Manual-ON Occupancy Sensor Remote

California Title 24 2005 Compliant

Cat. No. IPP0R

120VAC, 60Hz

No Minimum Load Required

Compatible with incandescent lamps, electronic and magnetic low-voltage ballasts, electronic and magnetic ballasts, and fans.

INSTALLATION INSTRUCTIONS

DI-000-IPP0R-02A

WARNINGS AND CAUTIONS:

• To be installed and/or used in accordance with appropriate electrical codes and regulations.

• If you are unsure about any part of these instructions, consult a qualified electrician.

• Controlling a load in excess of the specified ratings will damage the unit and pose risk of fire, electric

shock, personal injury or death. Check your load ratings to determine suitability for your application.

• Do not install this unit to control a receptacle.

WARNINGS AND CAUTIONS:

• The Manual-On Occupancy Sensor Remote is intended to replace a standard light switch.

• Do not touch the surface of the lens. Clean outer surface with a damp cloth only.

• Disconnect power at circuit breaker or fuse when servicing, installing or removing fixture.

• Use this device only with copper or copper clad wire. With aluminum wire use only devices marked CO/ALR or CU/AL.

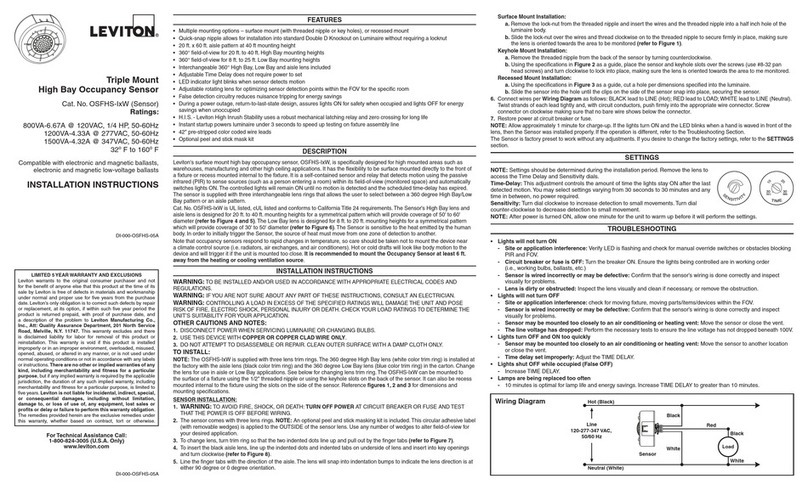

WIRING CONTROL (wall box with Load connection):

Connect wires per WIRING DIAGRAM as follows:

• Green or bare copper wire in wall box to Green terminal screw on control.

• Load wall box wire identified (tagged) when removing old switch to terminal screw

marked "RD" on control.

• First Traveler Line Hot to terminal screw marked "BK" on control.

• Remove Red insulating label from terminal screw marked "YL/RD" on control.

• Second Traveler wall box wire (note color as above) to terminal screw marked

"YL/RD" on control. This traveler from the control must go to the terminal screw on

the sensor remote marked "YL/RD".

• Line neutral wall box wire to terminal screw marked "WH" on control.

IPP0R Remote

(3-Way Wall box from Step 2)

VZ0SR Remote

(4-Way Box from Step 2)

Control

(3-Way Wall Box from Step 2)

Terminal

Screw marked

White (WH)

Terminal

Screw marked

White (WH)

Terminal

Screw marked

Red (RD)

BK WH

YL/RD

RD

3

2

1

4

5

Terminal

Screw marked

Yellow/Red

(YL/RD)

Terminal

Screw marked

Black (BK)

Terminal

Screw marked

White (WH)

BK WH

YL/RD

RD

4

3

5

1

2

Terminal

Screw marked

Yellow/Red

(YL/RD)

Terminal

Screw marked

Black (BK)

Additional

Neutral Wire

Additional

Neutral Wire

BK

YL/RD

WH

RD

4

3

5

6

2

1

Terminal

Screw marked

Yellow/Red

(YL/RD)

Terminal

Screw marked

Black (BK)

Hot (Black)

Neutral (White)

Control

IPP0R Remote VZ0SR Remote

YL/RD

YL/RD RD

WHWH BK

YL/RD

WH BK

BK

Line

120VAC, 60Hz

Black

White

Green

Ground

Green

Ground

LOAD

Green

Ground

4-Way Wiring with Sensor Remote for Controls with Neutral

Connection Application:

NOTE: IPP15 sensor is depicted as control device.

NOTE: The control must be installed in a wall box that has a Load connection. The

sensor remote must be installed in a wall box with a Line Hot connection and a Neutral

connection. A Neutral wire to the sensor remote needs to be added as shown.

If you are unsure about any part of these instructions, consult a qualified electrician.

NOTE: Maximum wire length from control to all installed remotes cannot exceed

300 ft (90 m).

WIRING SENSOR REMOTE (4-Way wall box with Line Hot connection):

Connect wires per WIRING DIAGRAM as follows:

• Green or bare copper wire in wall box to Green terminal screw on sensor remote.

• First Traveler and Third Traveler wall box wire to remote terminal screw marked "BK"

in 4-way box, and to terminal screw marked "BK" of the remaining remote in 3-way

box.

• Second Traveler (tagged) and Fourth Traveler (tagged) wall box wire from control

in 3-way box to sensor remote terminal screw marked "YL/RD" in 4-way box and to

terminal screw marked "YL/RD" of the remaining remote in 3-way box (note wire

colors). This traveler from the remotes must go to the terminal screw marked

"YL/RD" on the control.

• Line Neutral wall box wire to remote terminal screw marked "WH".

WIRING SENSOR REMOTE (3-Way wall box with Line Hot connection):

Connect wires per WIRING DIAGRAM as follows:

• Green or bare copper wire in wall box to Green terminal screw.

• Line Hot (common) wall box wire identified (tagged) when removing old switch and

First Traveler wall box wire to control terminal screw marked "BK".

• Second Traveler wall box wire from control to remote terminal screw marked "YL/RD"

(note wire color as above). This traveler from the remote must go to the terminal

screw marked "YL/RD" on the control.

• Line Neutral wall box wire to remote terminal screw marked "WH".

Step 4a cont’d

Step 4b

WIRING CONTROL (3-Way wall box with Load connection):

Connect wires per WIRING DIAGRAM as follows:

• Green or bare copper wire in wall box to Green terminal screw on control.

• Load wall box wire identified (tagged) when removing old switch to terminal

screw marked "RD" on control.

• First Traveler Line Hot to terminal screw marked "BK" on control.

• Remove Red insulating label from terminal screw marked "YL/RD" on control.

• Second Traveler wall box wire (note color as above) to terminal screw marked

"YL/RD" on control. This traveler from the control must go to the terminal screw

on the remote marked "YL/RD".

• Line Neutral wall box wire to terminal screw marked "WH" on control.

NOTE: The control must be installed in a wall box that has a Load connection.

The sensor remote must be installed in a wall box with a Line Hot connection and

a Neutral connection. A Neutral wire to the sensor remote needs to be added as

shown.

If you are unsure about any part of these instructions, consult a qualified

electrician.

NOTE: Maximum wire length from control to all installed remotes cannot

exceed 300 ft.

WIRING SENSOR REMOTE (wall box with Line Hot connection):

Connect wires per WIRING DIAGRAM as follows:

• Green or bare copper wire in wall box to Green terminal screw on sensor remote.

• Line Hot (common) wall box wire identified (tagged) when removing old switch

and First Traveler to terminal screw marked “BK” on control.

• Second Traveler wall box wire from control to sensor remote terminal screw

marked “YL/RD” (note wire color). This traveler from the remote must go to the

terminal screw on the control marked “YL/RD”.

• Line Neutral wall box to sensor remote terminal screw marked “WH”.

WIRING CONTROL (wall box with Load connection):

Connect wires per WIRING DIAGRAM as follows:

• Green or bare copper wire in wall box to Green terminal screw on control.

• Load wall box wire identified (tagged) when removing old switch to terminal

screw marked “RD” on control.

• First Traveler Line Hot to terminal screw marked “BK” on control.

• Remove Red insulating label from terminal screw marked “YL/RD” on control.

• Second Traveler wall box wire (note color as above) to terminal screw marked

“YL/RD” on control. This traveler from the control must go to the terminal screw

on the sensor remote marked “YL/RD”.

BK

YL/RDRD

4

3

2

1

5

Control

Terminal

Screw marked

White (WH)

BK WH

YL/RD

RD

4

3

5

1

2

IPP0R Remote

Terminal

Screw marked

Yellow/Red

(YL/RD)

Terminal

Screw marked

Black (BK)

Terminal

Screw marked

Yellow/Red

(YL/RD)

Terminal

Screw marked

Black (BK)

Additional

Neutral Wire

Terminal

Screw marked

Red (RD)

Hot (Black)

Neutral (White)

LOAD

Control

IPP0R Remote

YL/RD YL/RD

RD

WH BK BK

Black

White

Line

120VAC, 60Hz

Green

Ground

Green

Ground

Step 4b cont’d

3-Way Wiring with Sensor Remote Application:

NOTE: IPP15 sensor is depicted as control device.

Step 4c

Side Wire Connection

Side wire terminals accept

#14 AWG solid copper wire only.

Back Wire (either hole may be used)

Back wire openings use #14-12 AWG

solid copper wire only.

• Make sure that the ends of the wires from the wall box are straight (cut if necessary).

• Remove insulation from each wire in the wall box as shown.

Strip Gage (measure bare

wire here or use gage on

back of the sensor remote)

5/8”

(1.6 cm)

5/8”

(1.6 cm)

Step 3 cont’d

Strip Gage (measure bare

wire here or use gage on

back of the sensor remote)

Terminal

Screw marked

White (WH)

Terminal

Screw marked

White (WH)

Terminal

Screw marked

Red (RD)

BK WH

YL/RD

RD

BK WH

YL/RD

RD

4

3

5

1

2

3

2

1

4

5

ControlIPP0R Remote

Terminal

Screw marked

Yellow/Red

(YL/RD)

Terminal

Screw marked

Black (BK)

Terminal

Screw marked

Yellow/Red

(YL/RD)

Terminal

Screw marked

Black (BK)

Additional

Neutral Wire

Hot (Black)

Neutral (White)

ControlIPP0R Remote

YL/RD RD

WH BK

YL/RD

WH BK

Black

White

Line

120VAC, 60Hz

Green

Ground

Green

Ground

LOAD

NOTE: The control must be installed in a wall box that has a Load connection. The

sensor remote must be installed in a wall box with a Line Hot connection and a Neutral

connection. A Neutral wire to the sensor remote needs to be added as shown.

If you are unsure about any part of these instructions, consult a qualified electrician.

NOTE: Maximum wire length from control to all installed remotes cannot exceed

300 ft (90 m).

WIRING SENSOR REMOTE (wall box with Line Hot connection):

Connect wires per WIRING DIAGRAM as follows:

• Green or bare copper wire in wall box to Green terminal screw on sensor remote.

• Line Hot (common) wall box wire identified (tagged) when removing old switch and

First Traveler to terminal screw marked "BK" on control.

• Second Traveler wall box wire from control to sensor remote terminal screw marked

"YL/RD" (note wire color). This traveler from the sensor remote must go to terminal

screw marked "YL/RD" on the control.

• Line Neutral wall box to sensor remote terminal screw marked "WH".

3-Way Wiring with Sensor Remote for Controls with Neutral

Connection Application:

NOTE: IPP15 sensor is depicted as control device.

Step 4a

Tools needed to install your Remote:

Slotted/Phillips Screwdriver Electrical Tape

Pliers Pencil

Cutters Ruler

INSTALLING YOUR REMOTE

NOTE: Use check boxes when Steps are completed.

Step 2

Step 1

Step 3

/./&&

/./&&

/./&&

/./&&

/./&&

/./&&

/./&&/./&&

/./&&

/./&&

/./&&

/./&&

4-Way

1. First Traveler – note color

2. Second Traveler – tagged

3. Neutral

4. Ground

5. Third Traveler – note color

6. Fourth Traveler – tagged

NOTE: For matching remote

w/LEDs installation, the First

Traveler becomes Line Hot.

3-Way

1. Line or Load (See important

instruction below)

2. Neutral

3. Ground

4. First Traveler – note color

5. Second Traveler – note color

NOTE: For matching remote

w/LEDs installation, the First

Traveler becomes Line Hot.

Preparing and connecting wires:

This remote can be wired using side wire terminal screws or through

backwire openings. Choose appropriate wire stripping specifications

accordingly.

WARNING: TO AVOID FIRE, SHOCK, OR DEATH; TURN OFF

POWER at circuit breaker or fuse and test that power is off before wiring!

Identifying your wiring application (most common):

NOTE: If the wiring in the wall box does not resemble any of these

configurations, consult a qualified electrician.

IMPORTANT:

For 3-Way applications, note that one of the screw terminals from the old switch

being removed will usually be a different color (Black) or labeled Common. Tag that

wire with electrical tape and identify as the common (Line or Load) in both the sensor

wall box and remote wall box.

For 4-Way applications, note that the old switch being removed will have 4 screws

plus a ground screw. Tag the two same color insulated wires with electrical tape.