3 INSTALLATION INSTRUCTIONS

5

Assembly Length

Prior to ordering, use a metered pull tape in the conduit system to ensure that assemblies are

the correct length. Once the length of the conduit is determined, add 1% for measurement error,

plus the additional length needed to reach appropriate rack(s) and create desired service loops.

For example, if the metered tape result shows 500 ft.:

Example Length Calculation

Tape Results 500 ft.

1% for measurement error +5 ft.

Extension past conduit +10 ft.

Service Loops +15 ft.

Total assembly length 530 ft.

3.1 Cable Installation

3.1.1 Ensure that the conduit system size is large enough to accommodate

the cable.

a. OneReach Cable Assemblies follow the same fill-ratio standards as all other

low-voltage cable installations, as defined by NFPA 70, the National Electrical

Code (NEC).

b. The NEC defines the maximum amount of space that the installed cables should

occupy in a given size conduit. A single cable is allowed to occupy up to 53% of the

cross-sectional area (CSA) inside of a conduit. Two cables can occupy 31%. A 40%

maximum fill ratio is mandated for three or more cables.

c. If you do not have ready access to a fill-ratio calculator, the CSA can be manually

calculated by squaring the outside diameter of the cable (inside diameter of the conduit

for conduit CSA), and then multiplying the total by 0.7854.

NOTE: The number 0.7854 is arrived at by dividing πby four (3.1416 ÷ 4 = 0.7854).

d. Add the total of the cable CSA’s together.

e. Divide the total cable CSA by the conduit CSA.

NOTE: The cable’s pulling eye will need to fit into the conduit. Please see the OCA’s

product spec drawing for the pulling eye outer diameter (OD). For example, if the pulling

eye has a 0.8 inch OD, then a Trade Size 1 in. conduit will be needed.

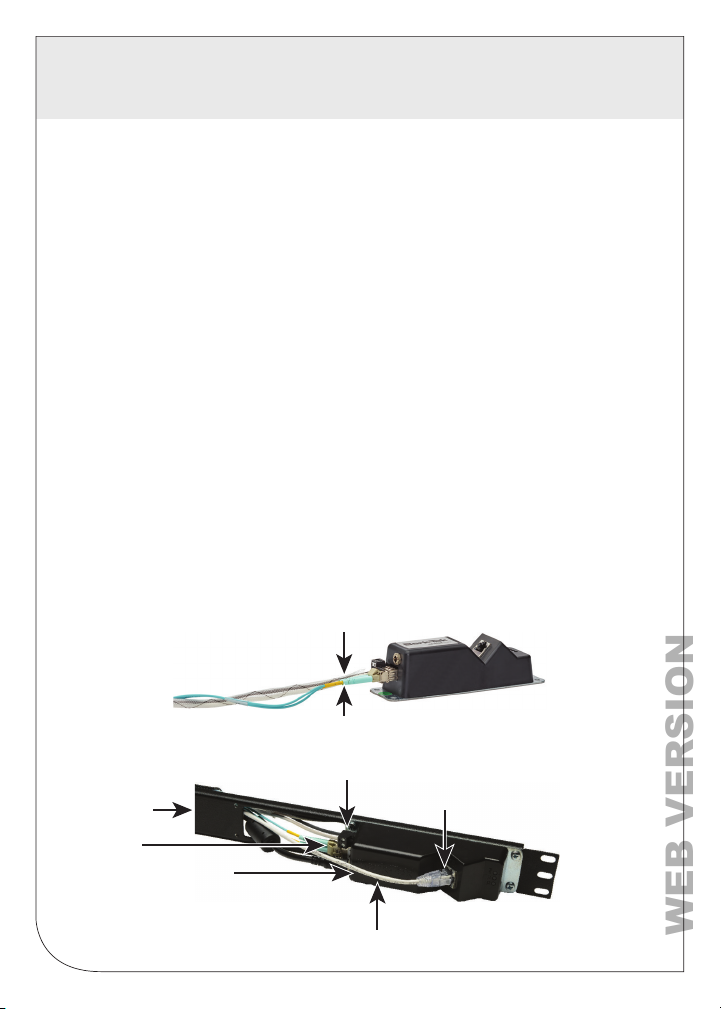

3.1.2 Stage pre-terminated cable at the remote location.

a. The pulling eye will be attached to the top end of the reel.

b. The cable must be placed on an axle that will allow the cable to easily unwind during

the pulling operation.

c. The cable should pull off the top of the reel.