8 300544652_002_C1 - 11/2016 - © Leybold

Technical Data

Measurement principle: Thermal conductivity according to a MEMS Pirani sensor

Measurement range (N2and Air): 5×10-5 to 1000 mbar

Accuracy(1) (N2): 5×10-4 to 1x10-3 mbar: ±10% of reading

1×10-3 to 100 mbar: ± 5% of reading

100 to 1000 mbar: ± 25% of reading

Repeatability(1) (N2): 1×10-3 to 100 mbar: ± 2% of reading

Supply Voltage: 9 –30 VDC

Power consumption: < 1.2 Watt

Fuse (thermal recoverable): 200 mA

Analog output (100 Ω impedance): 0.61 –10 VDC, Log. 1.286 VDC/decade

Analog output resolution: 16 bit

Analog output update rate: 16 Hz

Sensor fail, analog output: 0.5 V

Materials exposed to vacuum (2):

P/N: 230035V02 to 230043V02: 304 stainless steel, sealing material FPM

P/N: 230045V02, 230047V02: 304 stainless steel, sealing material FPM, Parylene-HT®

Setpoint relay(s):

P/N: 230035V02 to 230038V02: 0

P/N: 230040V02 to 230047V02: 2

Setpoint relay range: 2×10-4 to 1000 mbar

Setpoint relay contact rating: 1A / 30 VDC/AC (resistive load)

Setpoint relay response time: < 100 ms

Setpoint relay contact resistance: 100 mΩ (max)

Setpoint relay contact endurance: 100,000 cycles (min) (30 VDC/1 A load)

Setpoint relay contact endurance: 2,000,000 cycles (min) (30 VDC/0.2 A load)

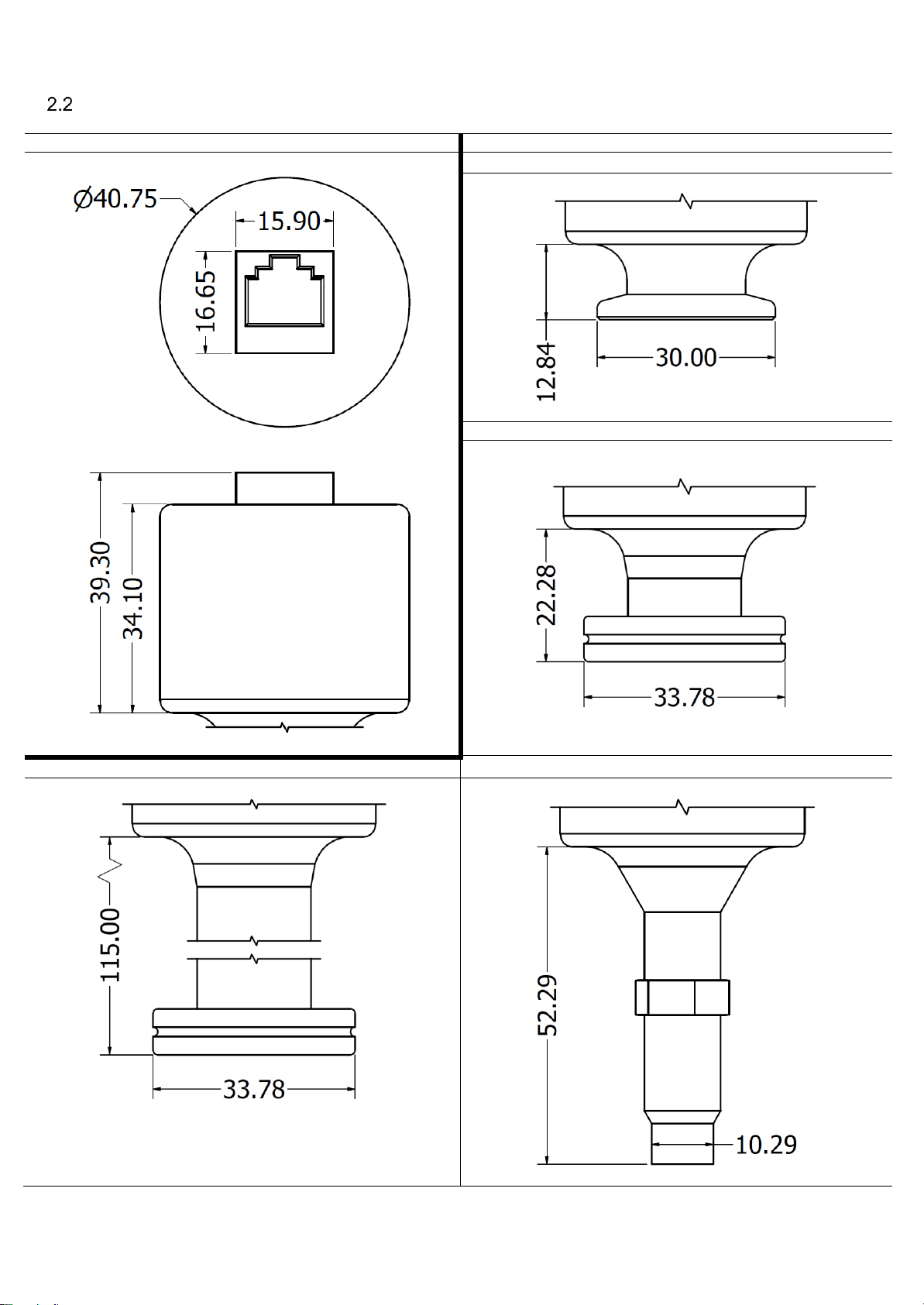

Internal volume:

P/N: 230035V02, 230040V02, 230045V02: KF16 2.80 cm3

P/N: 230036V02: CF 16 3.71 cm3

P/N: 230038V02, 230043V02: NPT 1/8” 3.04 cm3

P/N: 230037V02, 230047V02: CF 16 (bakeable) 23.14 cm3

Housing material: Stainless steel 304

Weight:

P/N: 230035V02, 230040V02, 230045V02: 168 g

P/N: 230036V02: 195 g

P/N: 230038V02, 230043V02: 183 g

P/N: 230037V02, 230047V02: 250 g

Maximum allowed pressure: 6 bar

Operating temperature: 0 to 40 °C (32 to 104 °F)

Bakeout temperature (Power off) (3): 85 °C (185 °F)

250 °C (482 °F) (only for P/N: 230037V02, 230047V02)(3)

Filament temperature: 35 °C above ambient temperature

Ingress Protection Rating: IP40

Leak rate < 5∙10-9 mbar∙l/s

(1) Accuracy and repeatability values are typical values measured in Nitrogen atmosphere at ambient temperature

after zero adjustment.

(2) For the full list of all materials exposed to process gases please contact Leybold.

(3) This bakeout temperature is only allowed at the end of the CF 16 flange. The temperature of the transmitter

must not exceed 85 °C (185 °F). Thus, it is not recommended to thermally insulate or directly heat the transmitter

and flange during bakeout.