5300710168_002_C1 - 01/2018 - © Leybold

Unpacking

Before unpacking your transmitter, check all surfaces of the packing material for shipping damage. Inspect for visible

damage. If found, notify the carrier immediately. Retain all packing materials for inspection. Do not use the TTR 91

R if it is damaged. If the TTR 91 R is not to be used immediately, replace the protective covers. Store the TTR 91 R

in suitable conditions as described in Technical Data section.

Please be sure that your transmitter package contains these items:

1 pcs. TTR 91 R

1 pcs. German short form manual (P/N: 300710168_001_C0)

1 pcs. English short form manual (P/N: 300710168_002_C0)

If any items are missing, please contact Leybold.

Description

The TTR 91 R is a Pirani gauge which measures vacuum pressures in the range 5×10-4 mbar to 1000 mbar. It

operates using the principle of thermal conductivity in which the rate of heat loss from a heated filament is dependent

on the pressure of gas surrounding the filament.

The TTR 91 R THERMOVAC transmitters can be used in a variety of applications as standalone units or with Graphix

controllers (P/N: 230680V01, 230681V01, 230682V01) and the Display controllers (P/N: 230001, 230024, 230025).

All THERMOVAC transmitters are backward compatible with Graphix, Display and Center controllers.

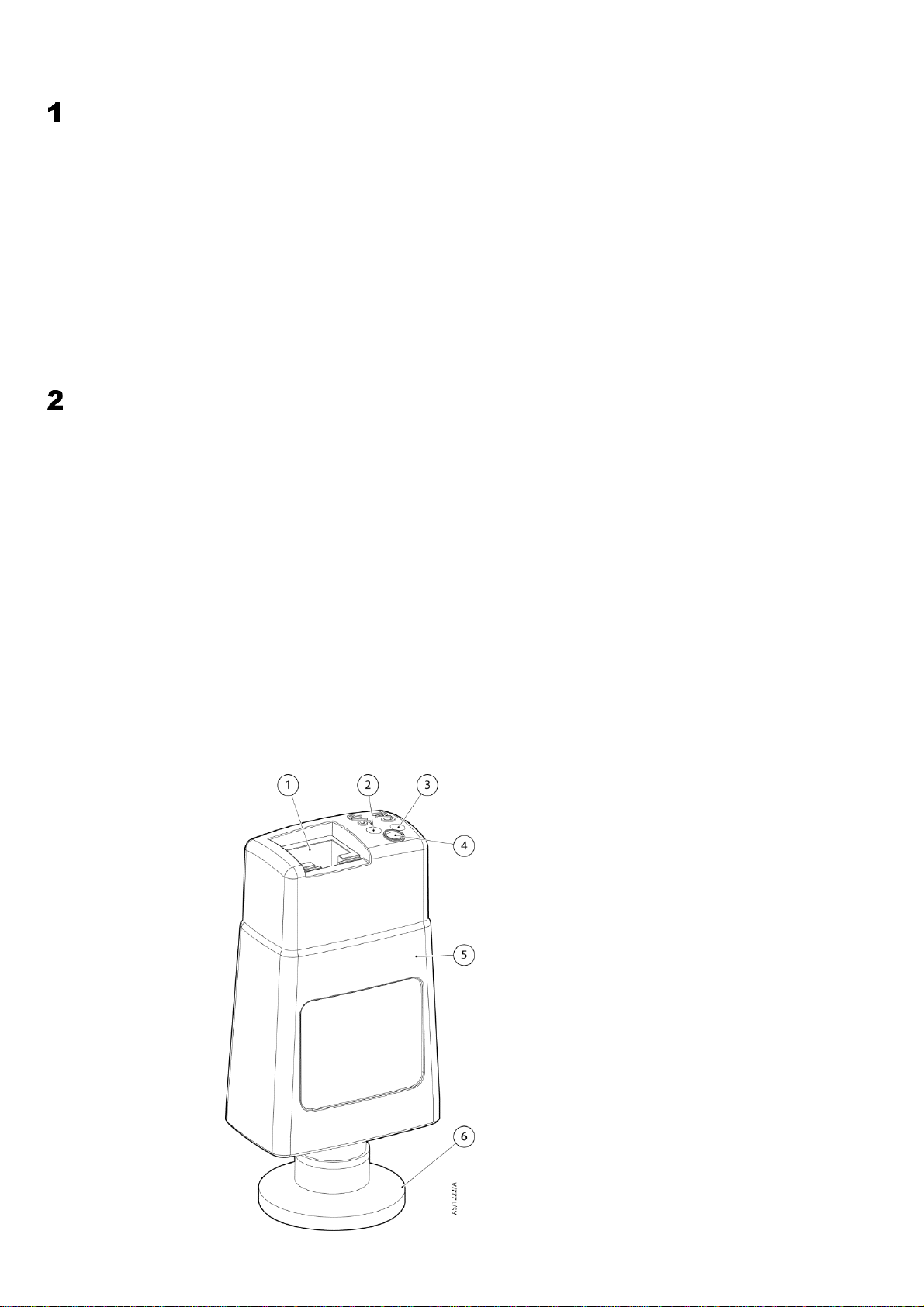

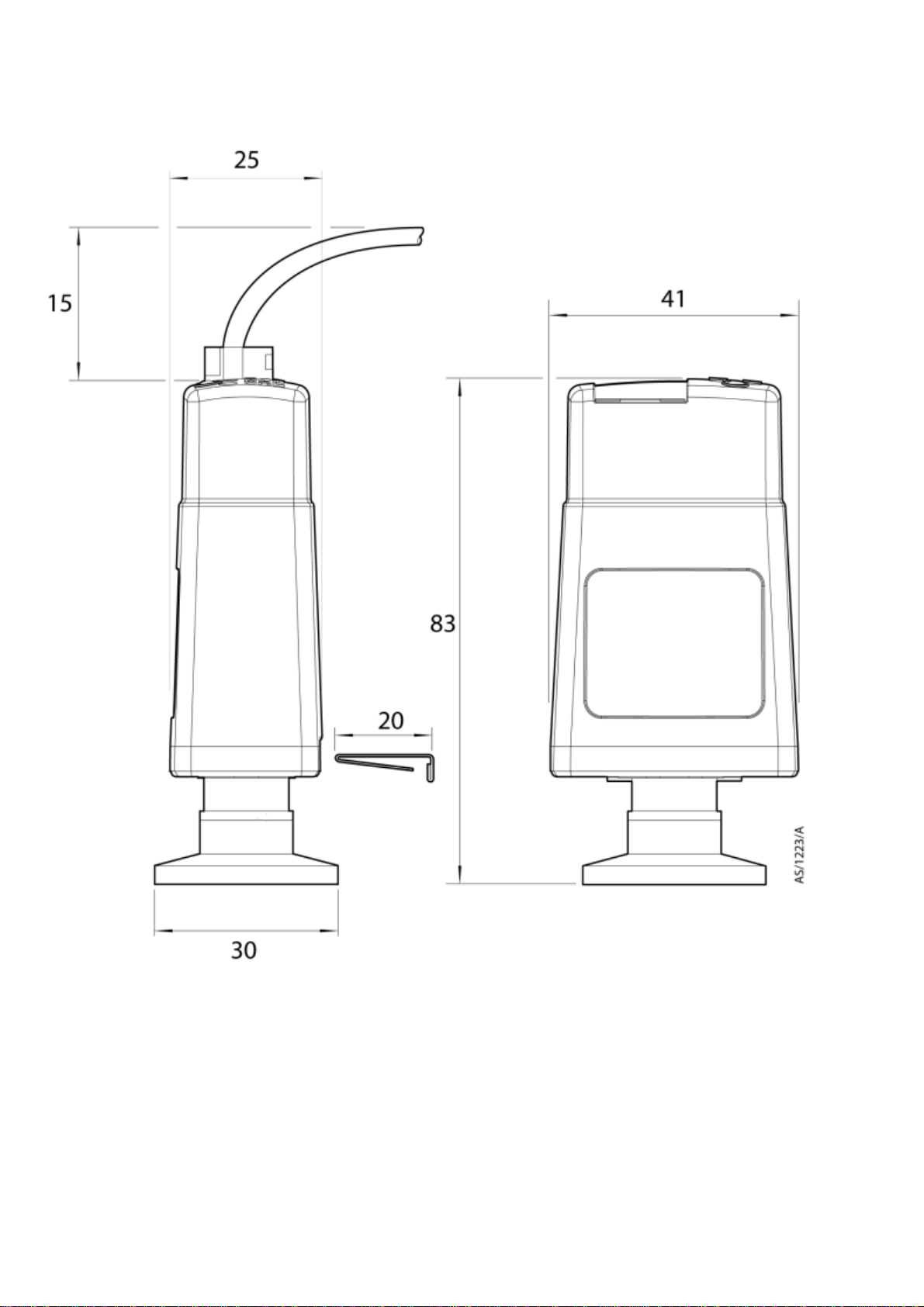

A general view of the gauge is shown below. The gauge features a detachable tube which allows a replacement to

be fitted in the event of contamination or failure of the filament. There are two push-button switches on the top of the

gauge. The switch labelled "CAL" is used for atmosphere and vacuum calibration and the switch labelled "S/P" is

used to adjust the set-point threshold.

The transmitters have one programmable set-point (transistor output) which can be used for process control, for

example interlocking valves or pumps. The analogue voltage output can be interfaced to external analogue

equipment for pressure readout or controlling.

General view of the TTR 91 R

1

Electrical connector

2

Set-point button

3

CAL button

4

Status LED

5

Electronics housing

6

Vacuum flange