2Room Air Conditioner

Air Conditioner Service Manual

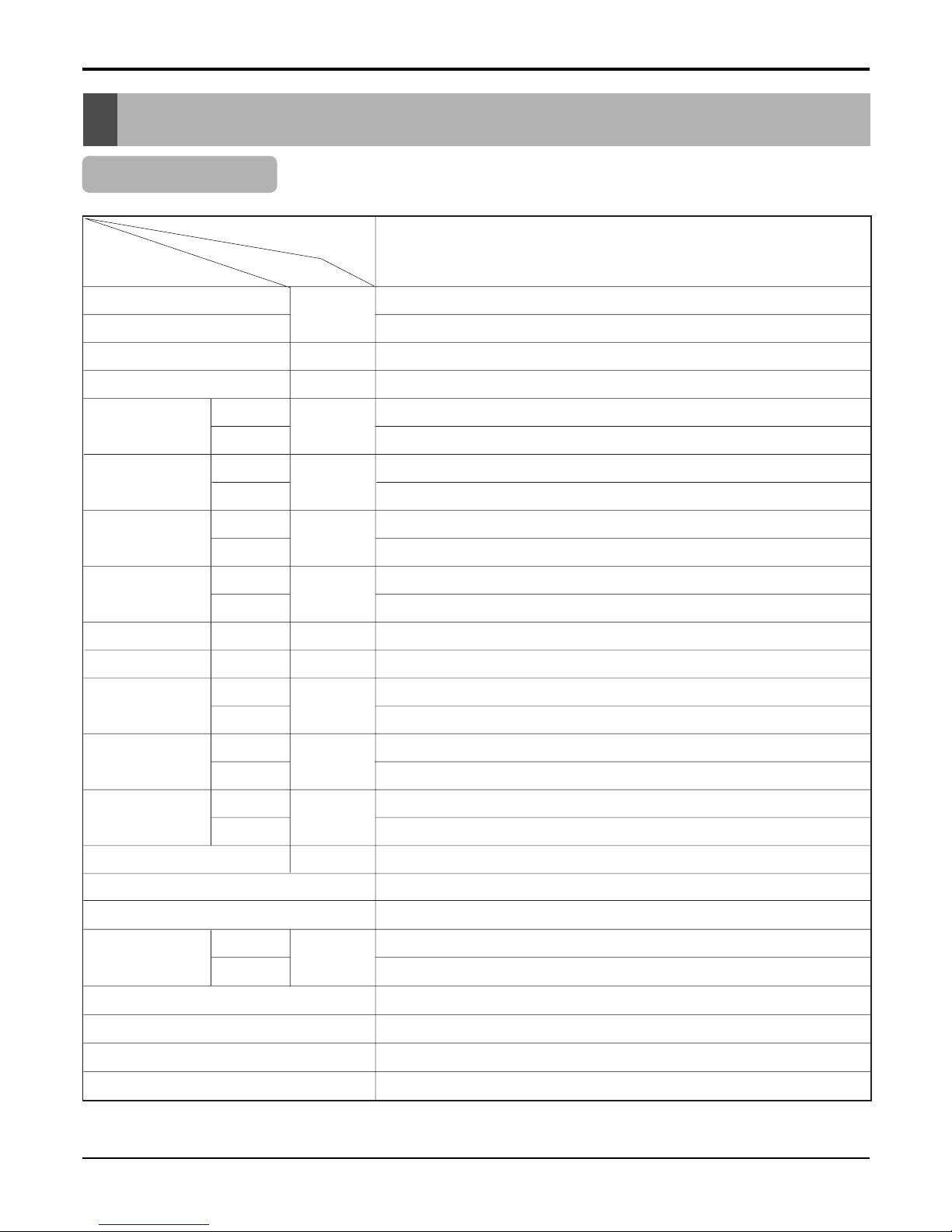

TABLE OF CONTENTS

LG Model Name ...............................................................................................................................................3

Safety Precautions..........................................................................................................................................4

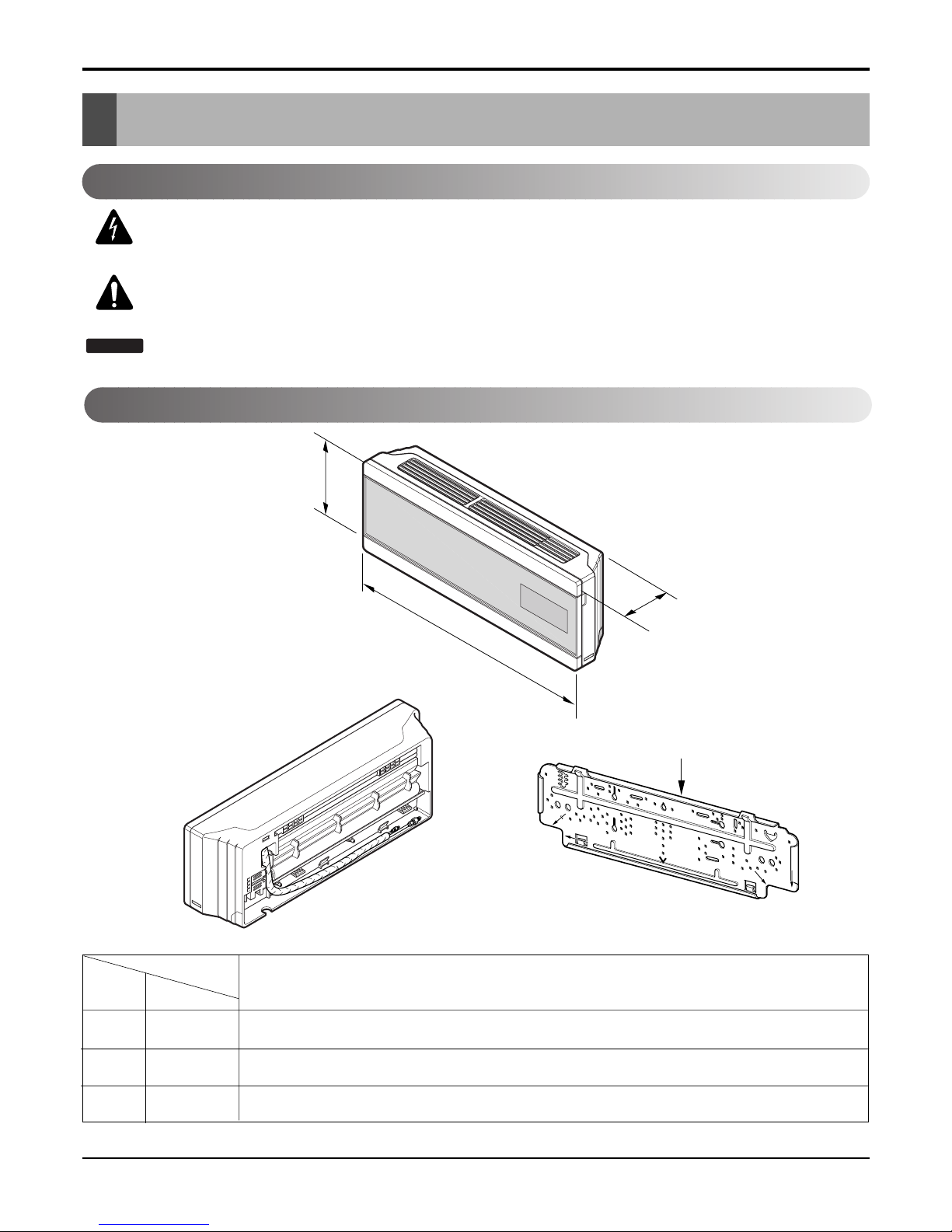

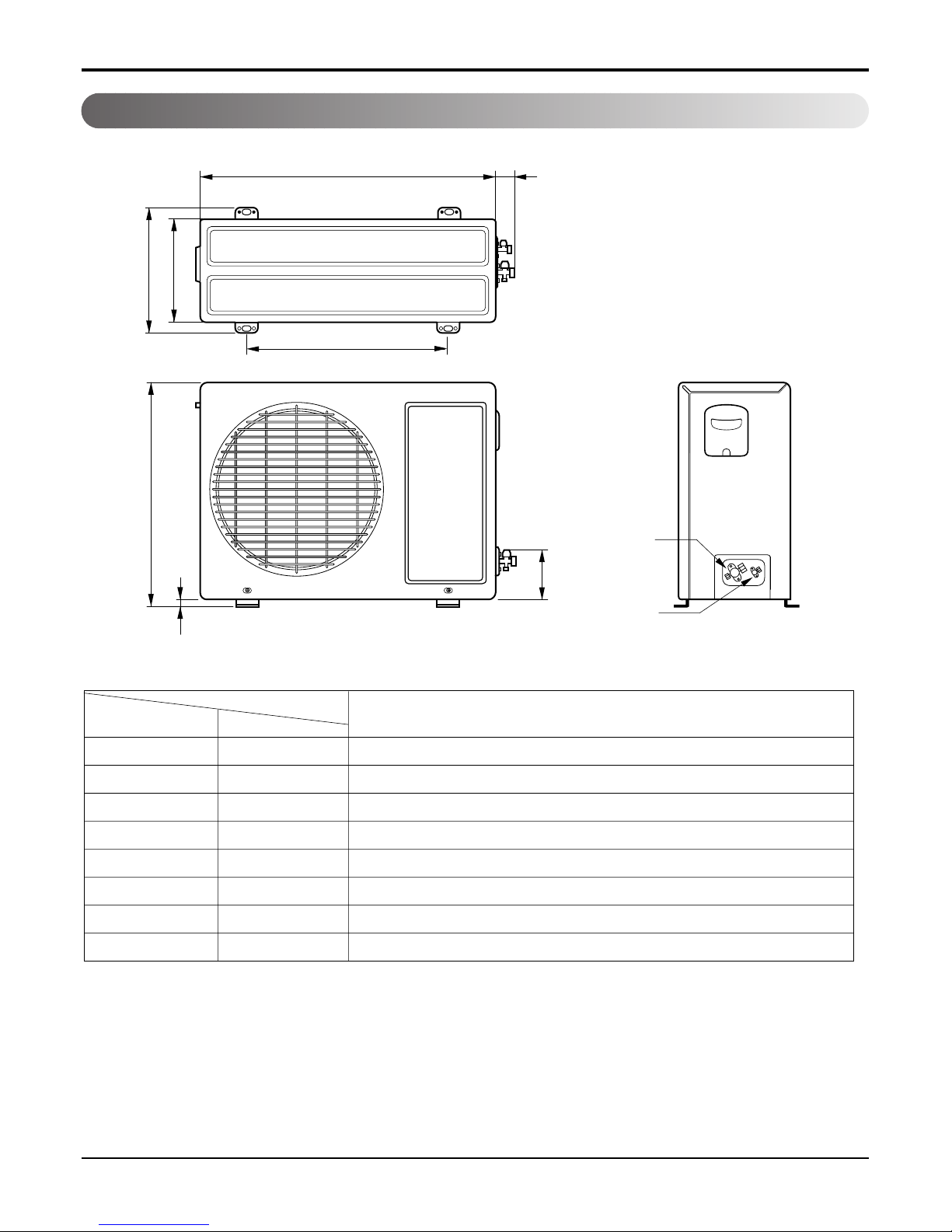

Dimensions .....................................................................................................................................................8

Symbols used in this Manual......................................................................................................................8

Indoor Unit..................................................................................................................................................9

Outdoor Unit...............................................................................................................................................9

Product Specifications ................................................................................................................................10

Installation .....................................................................................................................................................11

Select the Best Location .........................................................................................................................11

Piping Length and Elevation.....................................................................................................................11

Fixing Installation Plate ............................................................................................................................12

Drill a Hole in the wall...............................................................................................................................12

Flaring Work.............................................................................................................................................13

Connecting the Piping ..............................................................................................................................14

Connecting the Cables.............................................................................................................................19

Connection method of the connecting cable(Example)............................................................................20

Connect the cable to the indoor unit.........................................................................................................21

Checking the Drainage.............................................................................................................................22

Forming the Piping ...................................................................................................................................23

Air Purging ...............................................................................................................................................24

Test Running ............................................................................................................................................26

Operation ......................................................................................................................................................28

Function of Controls .................................................................................................................................28

Display Function.......................................................................................................................................34

Self-diagnosis Function............................................................................................................................34

Remote Control Operations......................................................................................................................35

Disassembly ..................................................................................................................................................36

Indoor Unit................................................................................................................................................36

Schematic Diagram.......................................................................................................................................39

Electric control Device..............................................................................................................................39

Wiring Diagram.........................................................................................................................................41

Components Location ..............................................................................................................................42

Troubleshooting Guide .................................................................................................................................46

Refrigeration Cycle Diagram ....................................................................................................................46

2-way, 3-way Valve ...................................................................................................................................47

Cycle Parts...............................................................................................................................................52

Electronic Parts ........................................................................................................................................53

Exploded View & Replacement Parts List .................................................................................................62

Indoor Unit...............................................................................................................................................63

Outdoor Unit............................................................................................................................................64