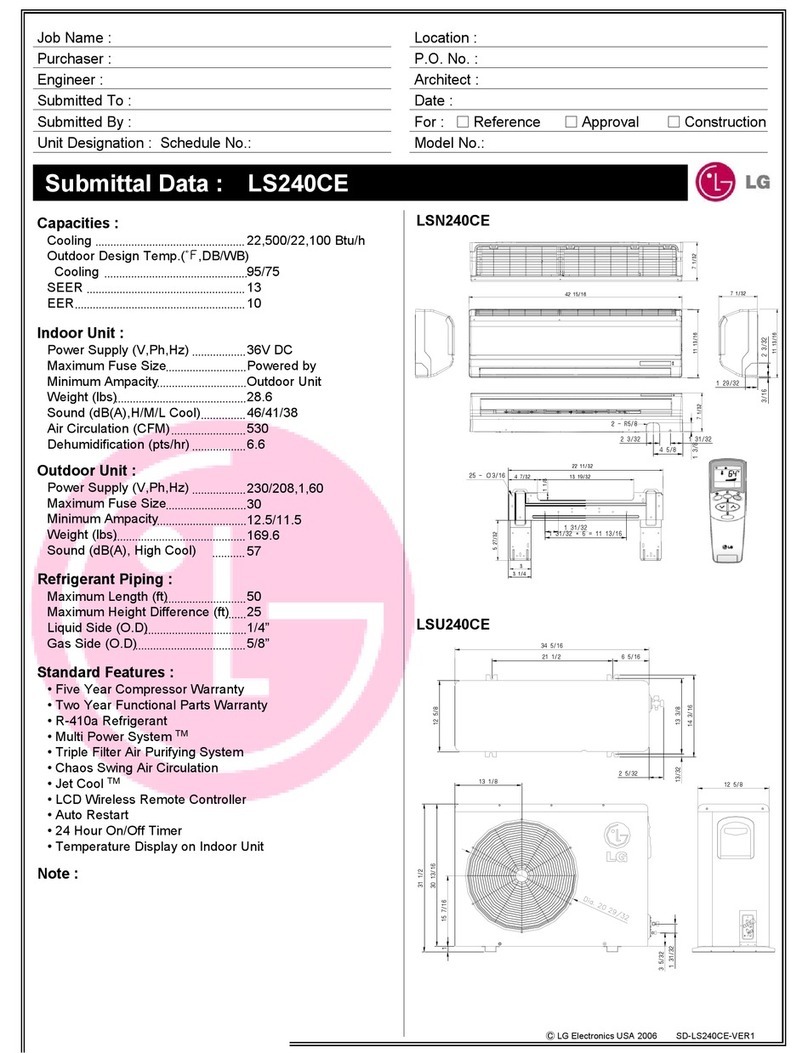

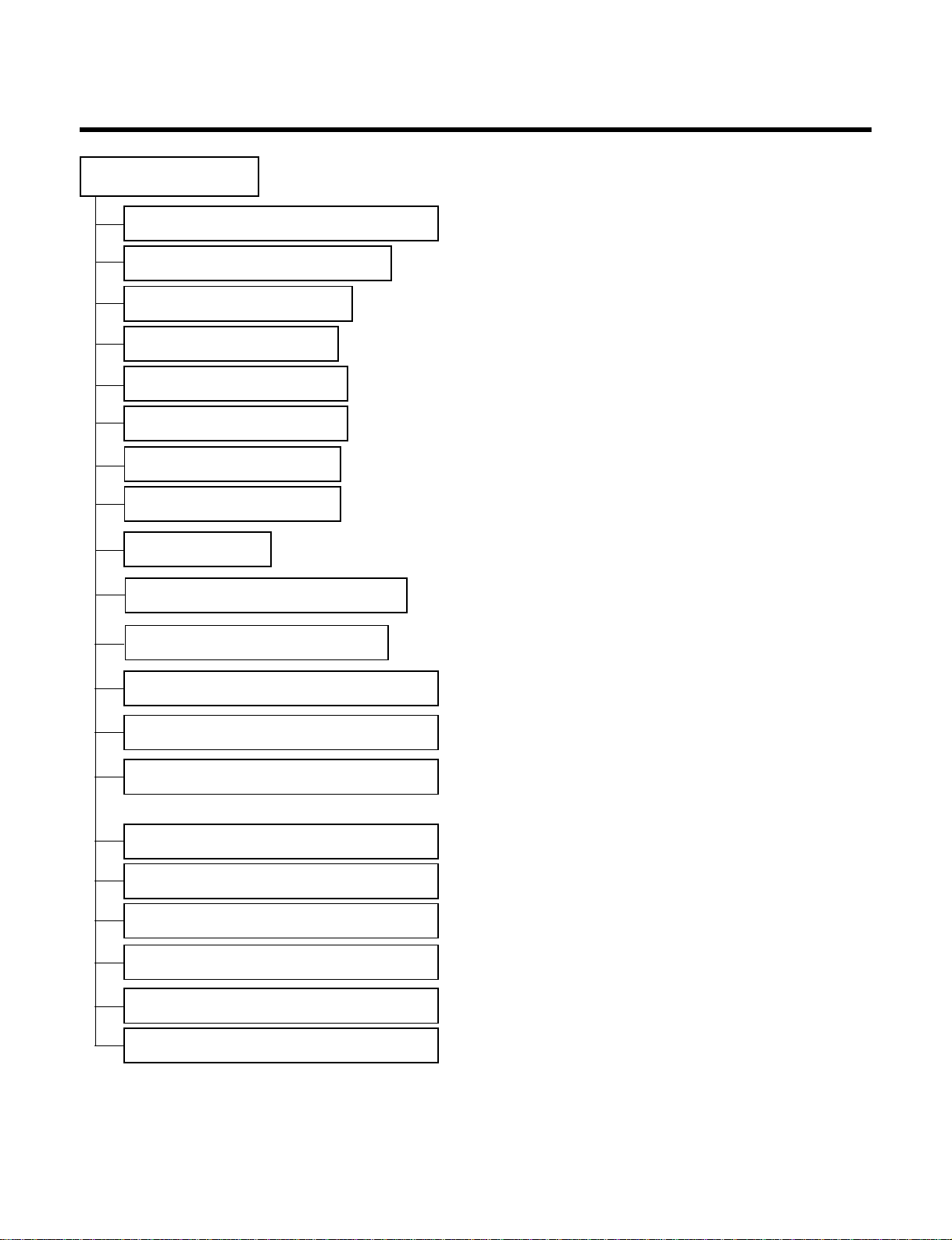

Model

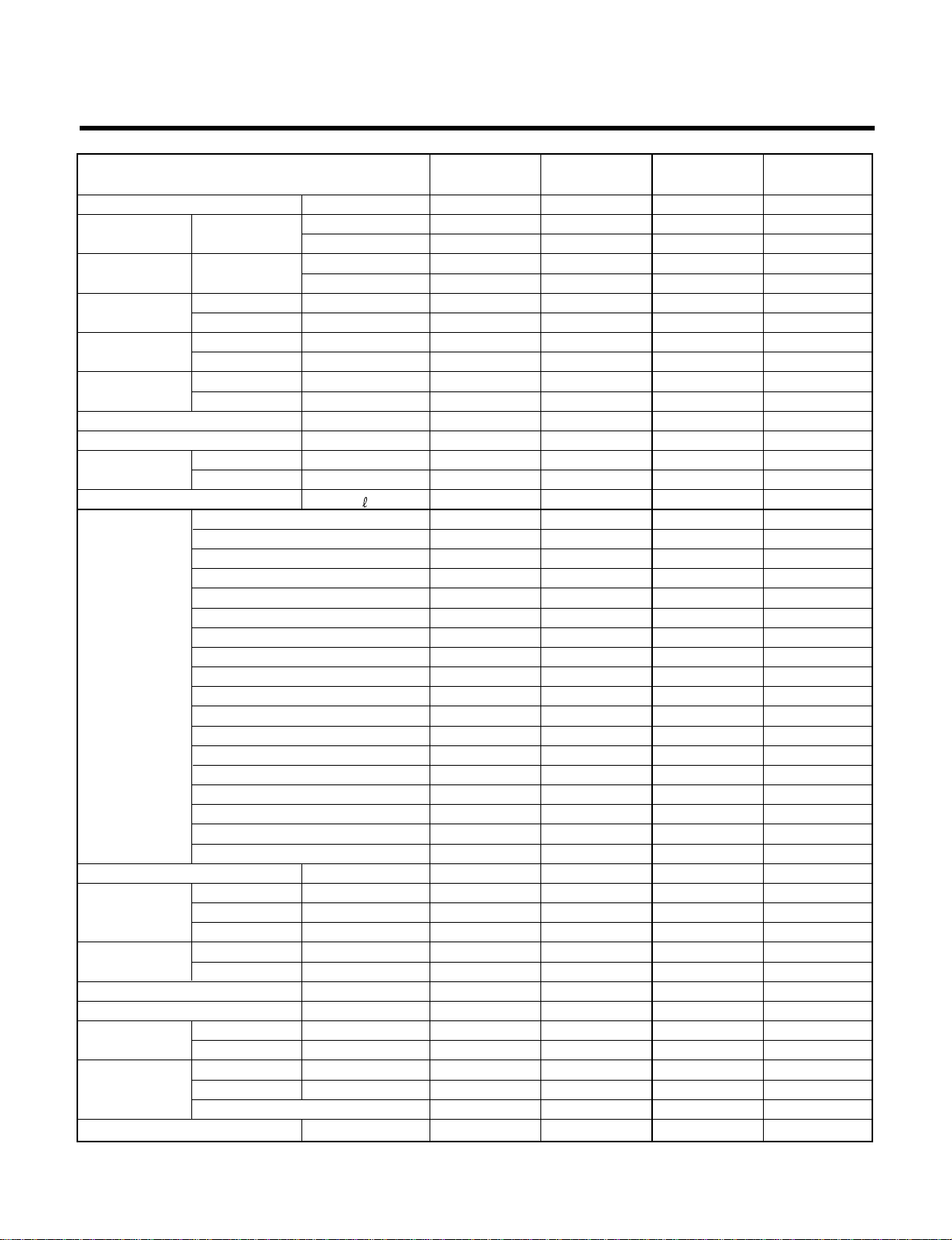

3, 380-415, 50 3, 380-415, 50 3, 380-415, 50 3, 380-415, 50

13,608(15,826) 13,608(15,826) 13,608(15,826) 13,608(15,826)

54,000 54,000 54,000 54,000

13,608(15,826) 13,608(15,826) - -

54,000 54,000 - -

5,600 5,600 5,600 5,600

4,850 4,850 - -

9.5 9.5 9.5 9.5

8.4 8.4 - -

79 79 79 79

79 79 - -

2.43 2.43 2.43 2.43

3.26 3.26 - -

36 36 36 36

58 58 58 58

5.8 5.8 5.8 5.8

OO OO

OO XX

44 44

OO OO

OO OO

OO OO

OO OO

OO OO

44 44

OO OO

OO XX

OO OO

OO OO

OO OO

OO OO

Option Option Option Option

OO OO

OX OX

5,800 5,800 5,700 5,700

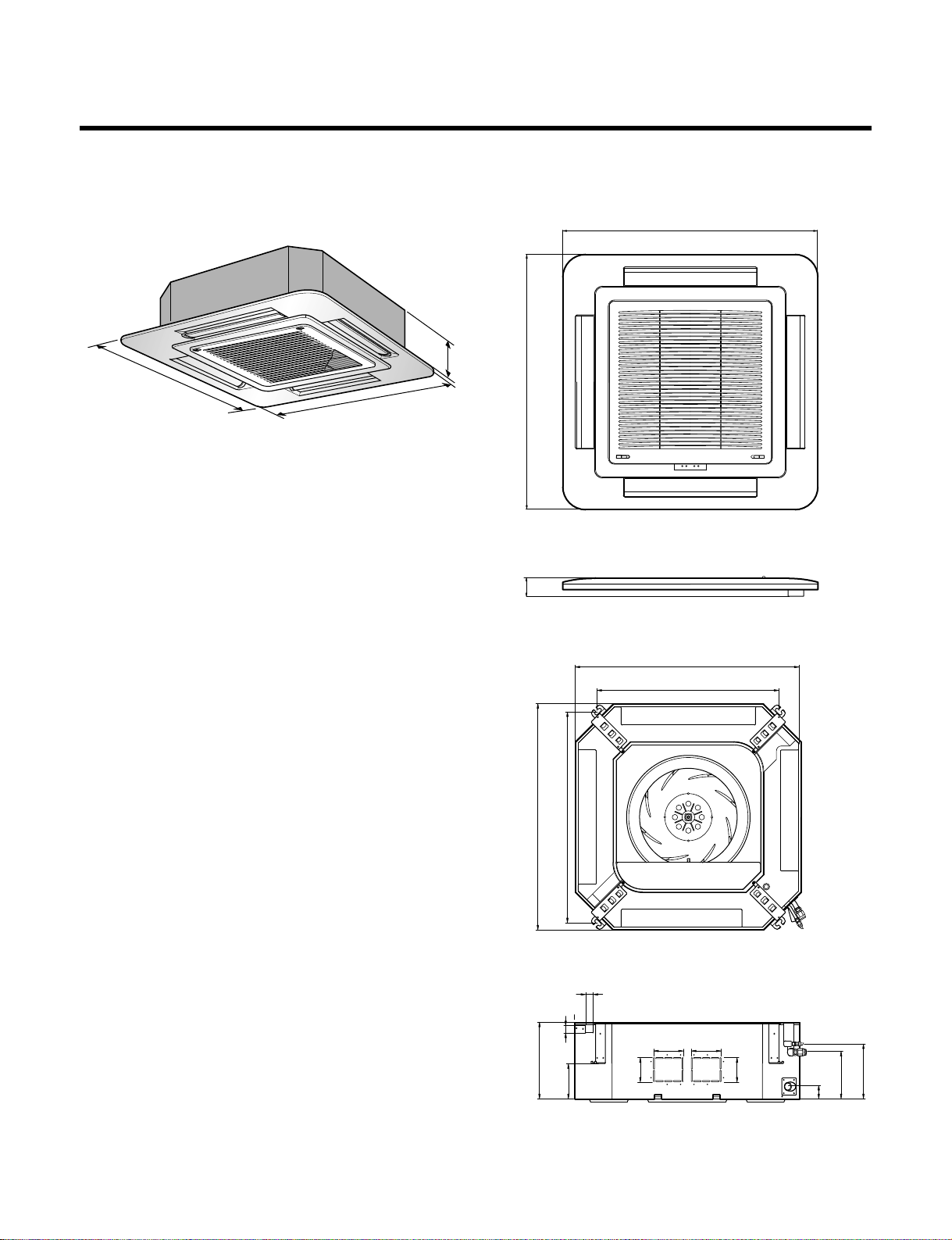

840*840*288 840*840*288 840*840*288 840*840*288

950*950*30 950*950*30 950*950*30 950*950*30

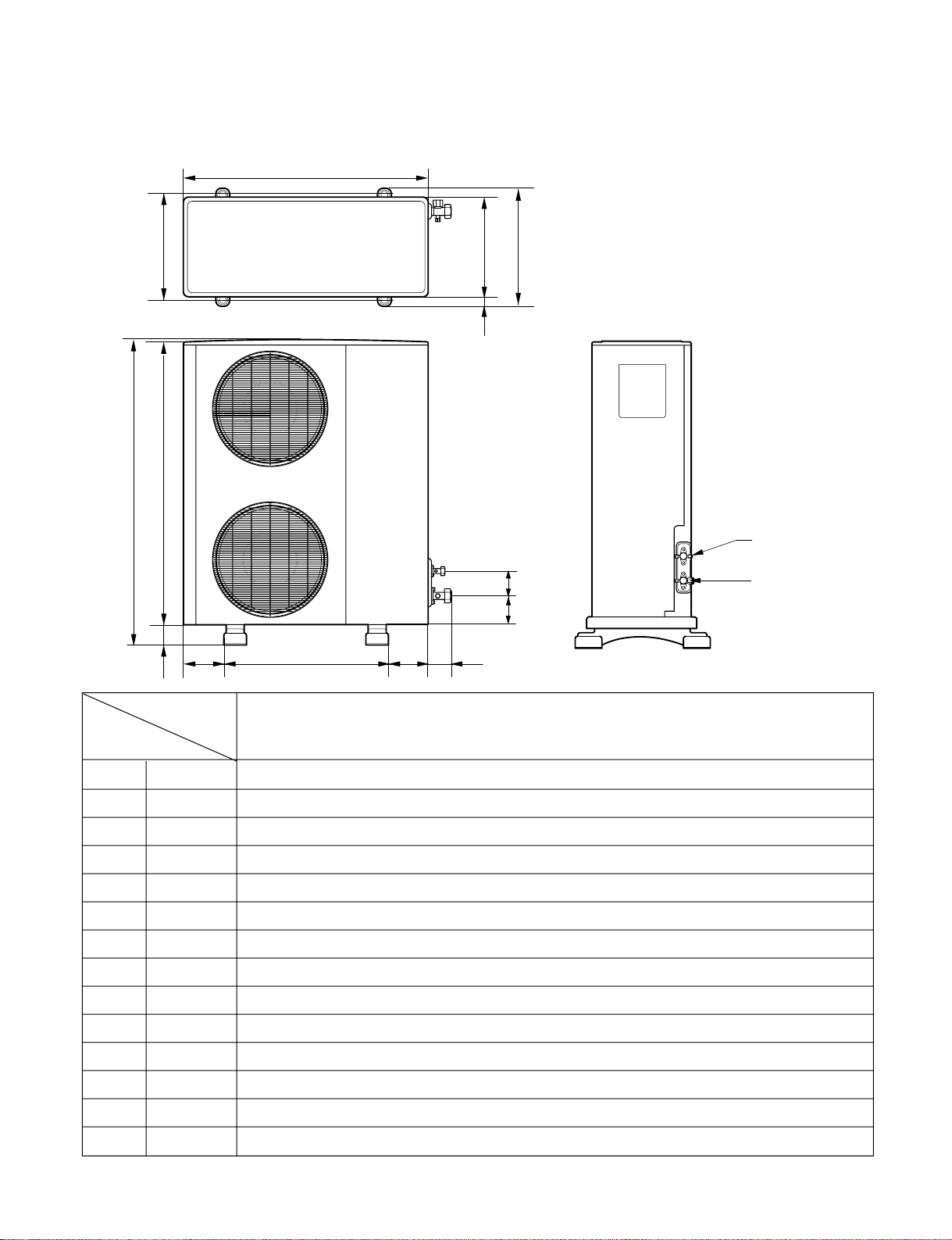

900*1,225*370 900*1,225*370 900*1,225*370 900*1,225*370

32 32 32 32

95 95 95 95

12 : 4*3.5 12 : 4*3.5 12 : 4*3.5 12 : 4*3.5

16 : 5*1.25 16 : 5*1.25 16 : 5*1.25 16 : 5*1.25

1/2(12.7) 1/2(12.7) 1/2(12.7) 1/2(12.7)

3/4(19.05) 3/4(19.05) 3/4(19.05) 3/4(19.05)

50 50 50 50

30 30 30 30

FoamPE/5mm FoamPE/5mm FoamPE/5mm FoamPE/5mm

Ø25 / 32 Ø25 / 32 Ø25 / 32 Ø25 / 32

LT-D5480HA LT-D5480HL LT-D5480CA LT-D5480CL

Power Supply ø, V, Hz

Capacity Cooling kcal/h(W)

Btu/h

Heating kcal/h(W)

Btu/h

Input Cooling W

Heating W

Running Current Cooling A

Heating A

Starting Current Cooling A

Heating A

E.E.R kcal/h(W)

C.O.P W/W

Air Circulation Indoor m3/min

Outdoor m3/min

Moisture Removal / h

Air-Flow Direction Control

Heating Operation Mode

Fan Speeds (steps)

Auto Operation (Changeover)

Forced Operation

Jet Cool

Soft Dry Operation

Timer Delay Safety Function

Feature Air Deflection (Way)

Self Diagnosis

Hot start

Auto Restart

Air refresh (Hole)

High Ceiling

Group Control (Optional wiring)

Central Control

Wired remote controller (with weekly Program)

Plasma A/Cleaner

Refrigerant(R-22) Charge g

Dimensions Indoor mm

(W x D x H) Panel mm

Outdoor mm

Net Weight Indoor kg

Outdoor kg

Main Power Cord AWG#:P*mm2

Connection Cable AWG#:P*mm2

Service Valve Liquid Inch (mm)

Gas Inch (mm)

Installation Pipe Length (m)

Elevation (m)

Insulation(material/thickness)

Drain Hose(I.D/O.D) mm

Product Specifications (Cooling & Heating)

–5–