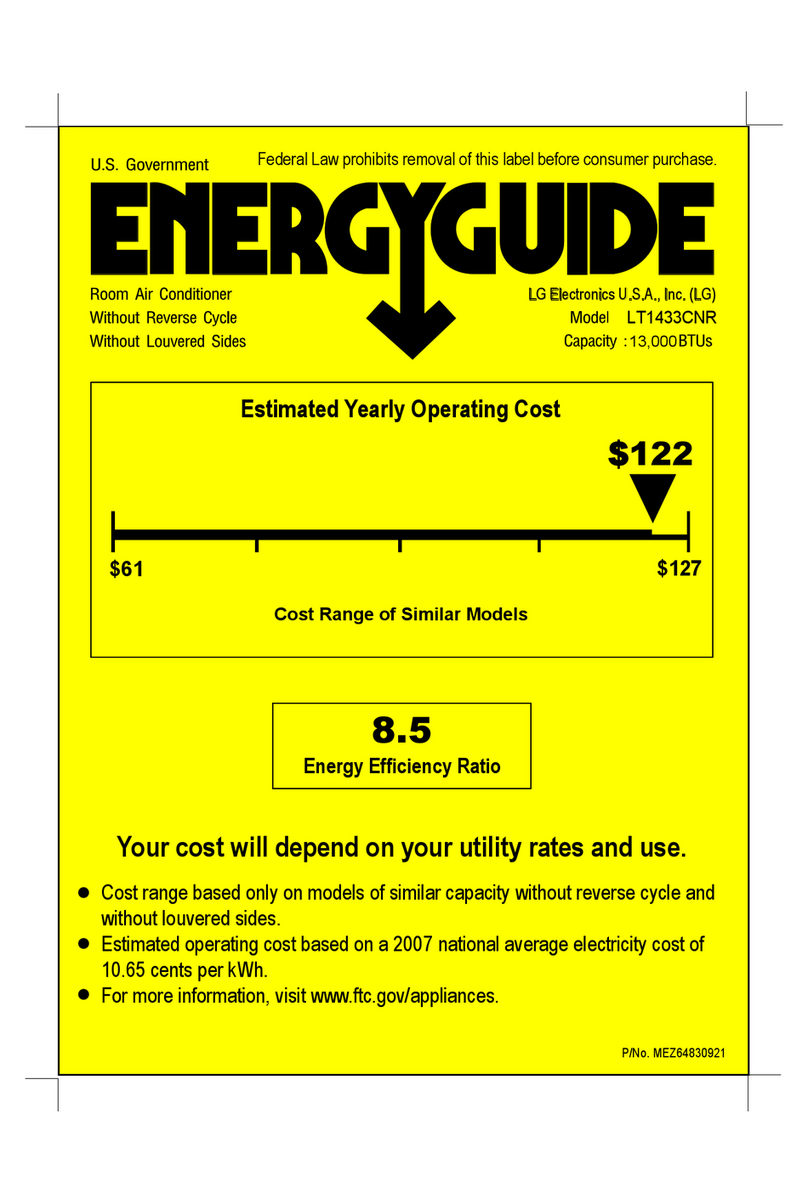

2Room Air Conditioner

Air Conditioner Service Manual

TABLE OF CONTENTS

LG Model Name ...............................................................................................................................................3

Safety Precautions..........................................................................................................................................5

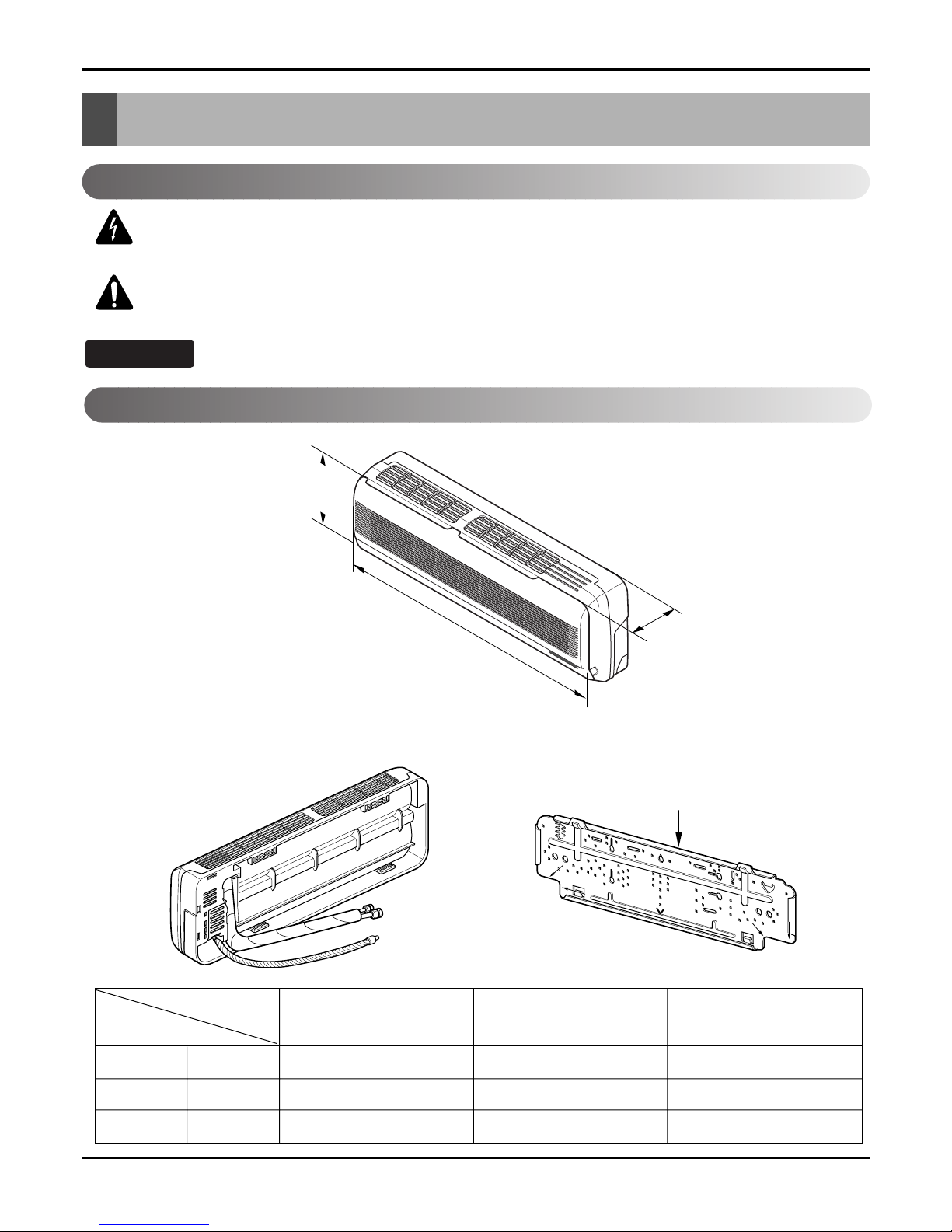

Dimensions....................................................................................................................................................10

Symbols Used in this Manual...................................................................................................................10

Indoor Unit................................................................................................................................................10

Outdoor Unit.............................................................................................................................................11

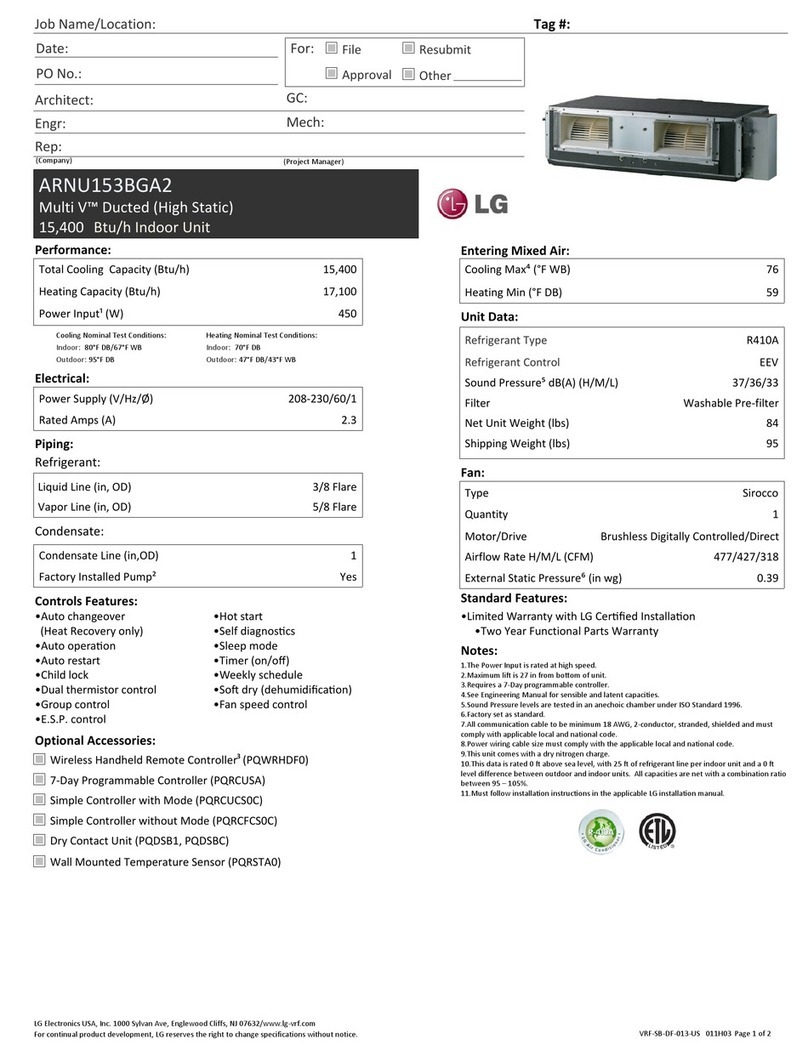

Product Specifications .................................................................................................................................14

Installation .....................................................................................................................................................16

Selection of the Best Location..................................................................................................................16

Piping Length and Elevation.....................................................................................................................16

How to Fix Installation Plate .....................................................................................................................17

Drill a Hole in the Wall ..............................................................................................................................17

Drain hose junction...................................................................................................................................17

Flaring work and connection of piping .......................................................................................................18

Flaring work..............................................................................................................................................18

Connection of Piping Indoor.....................................................................................................................18

Connection of the Pipes-Outdoor.............................................................................................................22

Connecting the cable between indoor unit and outdoor unit ...................................................................23

Connect the Cable to the Indoor Unit.......................................................................................................23

Connect the Cable to the Outdoor Unit ....................................................................................................24

Checking the drainage and forming the pipings........................................................................................25

Checking the Drainage.............................................................................................................................25

Form the Piping........................................................................................................................................25

AIR PURGING ................................................................................................................................................26

Air purging................................................................................................................................................26

Air purging with vacuum pump .................................................................................................................26

Test Running .................................................................................................................................................28

Operation .......................................................................................................................................................29

Function of Controls .................................................................................................................................29

Display Function ......................................................................................................................................33

Self-diagnosis Function............................................................................................................................33

Remote Control Operations......................................................................................................................34

Disassembly ..................................................................................................................................................35

Indoor Unit................................................................................................................................................35

Schematic Diagram.......................................................................................................................................38

Electric Control Device .............................................................................................................................38

Wiring Diagram.........................................................................................................................................39

Components Location ..............................................................................................................................40

Troubleshooting Guide .................................................................................................................................42

Refrigeration Cycle Diagram ....................................................................................................................42

2-way, 3-way Valve .................................................................................................................................43

Cycle Parts...............................................................................................................................................49

Electronic Parts ........................................................................................................................................50

Exploded View...............................................................................................................................................57

Replacement Parts List ................................................................................................................................62