—2—

1. PREFACE

1.1 SAFETY PRECAUTIONS ...............................2

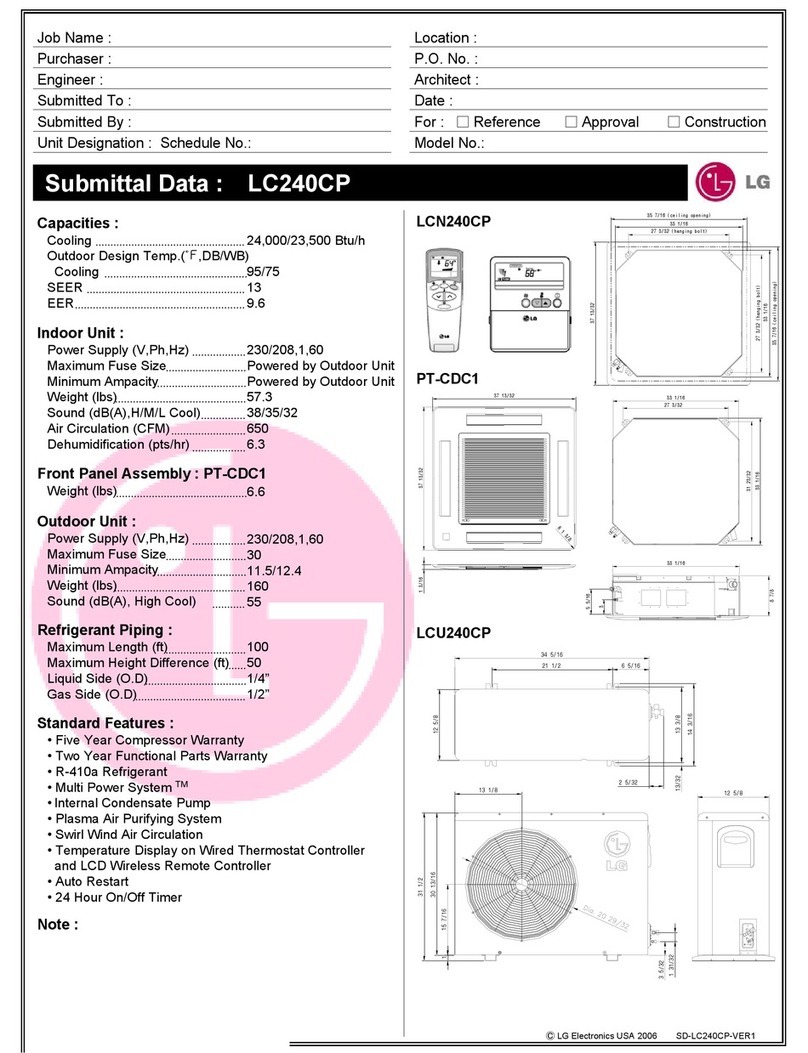

1.2 INSULATION RESISTANCE TEST.................2

1.3 SPECIFICATIONS ..........................................3

1.4 FEATURES.....................................................4

1.5 CONTROL LOCATIONS.................................4

2.

DISASSEMBLY INSTRUCTIONS

2.1 MECHANICAL PARTS....................................5

2.1.1 FRONT GRILLE.....................................5

2.1.2 CABINET................................................5

2.1.3 CONTROL BOX.....................................5

2.2 AIR HANDLING PARTS..................................6

2.2.1 COVER (AT THE TOP)..........................6

2.2.2 BLOWER................................................6

2.2.3 FAN........................................................6

2.2.4 SHROUD................................................7

2.3 ELECTRICAL PARTS.....................................7

2.3.1 MOTOR..................................................7

2.3.2 COMPRESSOR.....................................7

2.3.3 CAPACITOR..........................................8

2.3.4 POWER CORD......................................8

2.3.5 THERMOSTAT ......................................8

2.3.6 ROTARY SWITCH.................................9

2.3.7 SYNCHRONOUS MOTOR ....................9

2.4 REFRIGERATION CYCLE.................................10

2.4.1 CONDENSER......................................10

2.4.2 EVAPORATOR....................................10

2.4.3 CAPILLARY TUBE...............................10

3.

TROUBLESHOOTING GUIDE

3.1 OUTSIDE DIMENSIONS...............................13

3.2 PIPING SYSTEM ..........................................13

3.3 TROUBLESHOOTING GUIDE......................14

4. SCHEMATIC DIAGRAM

4.1 CIRCUIT DIAGRAM......................................19

5. EXPLODED VIEW..................................20

6. REPLACEMENT PARTS LIST.......21

1. PREFACE

This SERVICE MANUAL provides various service information, including the mechanical and electrical

parts etc. This room air conditioner was manufactured and assembled under a strict quality control system.

The refrigerant is charged at the factory. Be sure to read the safety precautions prior to servicing the unit.

1.1 SAFETY PRECAUTIONS

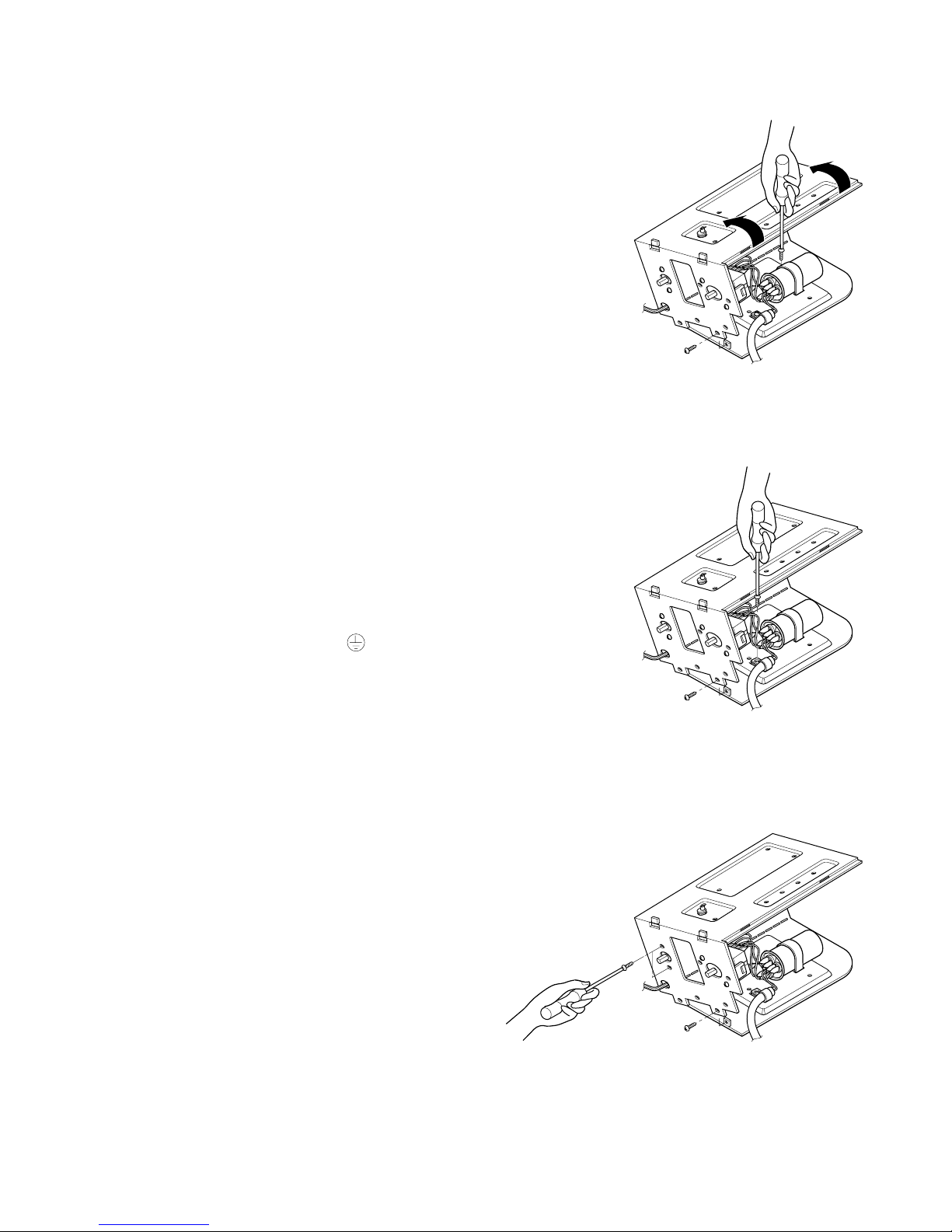

1. When servicing the unit, set the ROTARY SWITCH

or POWER SWITCH to OFF and unplug the power

cord.

2. Observe the original lead dress.

If a short circuit is found, replace all parts which

have been overheated or damaged by the short

circuit.

3. After servicing the unit, make an insulation

resistance test to protect the customer from being

exposed to shock hazards.

1.2

INSULATION RESISTANCE TEST

1. Unplug the power cord and connect a jumper

between 2 pins (black and white).

2. The grounding conductor (green or green & yellow)

is to be open.

3. Measure the resistance value with an ohm meter

between the jumpered lead and each exposed

metallic part on the equipment at all the positions

(except OFF or O) of the ROTARY SWITCH.

4. The value should be over 1MΩ.

CONTENTS