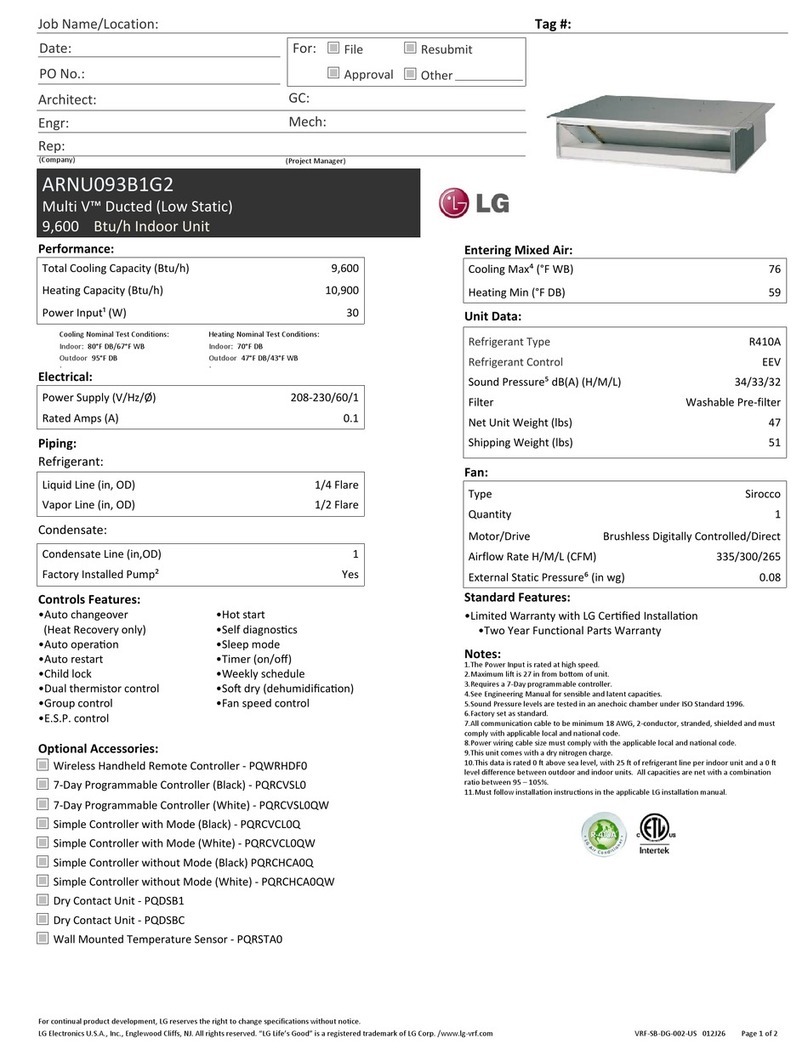

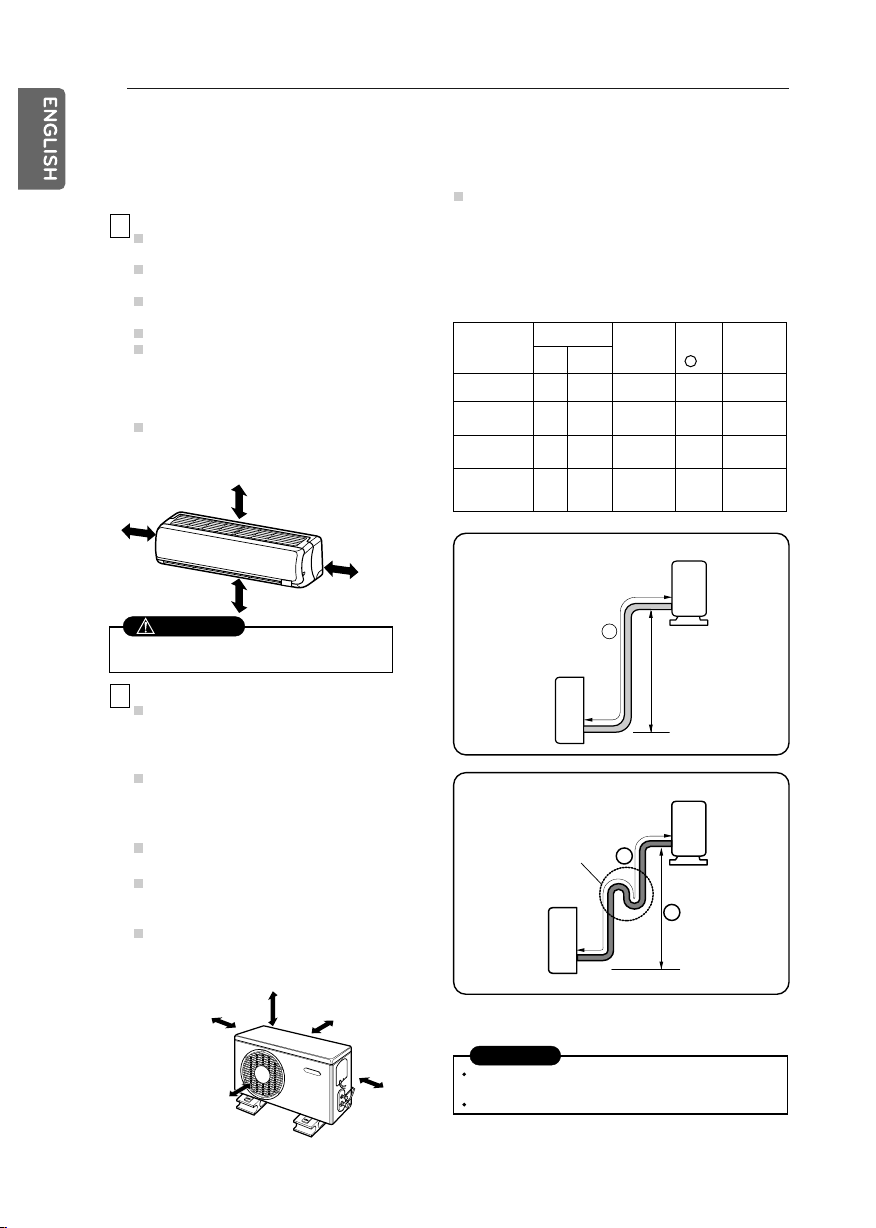

INSTALLATION OF INDOOR & OUTDOOR UNIT

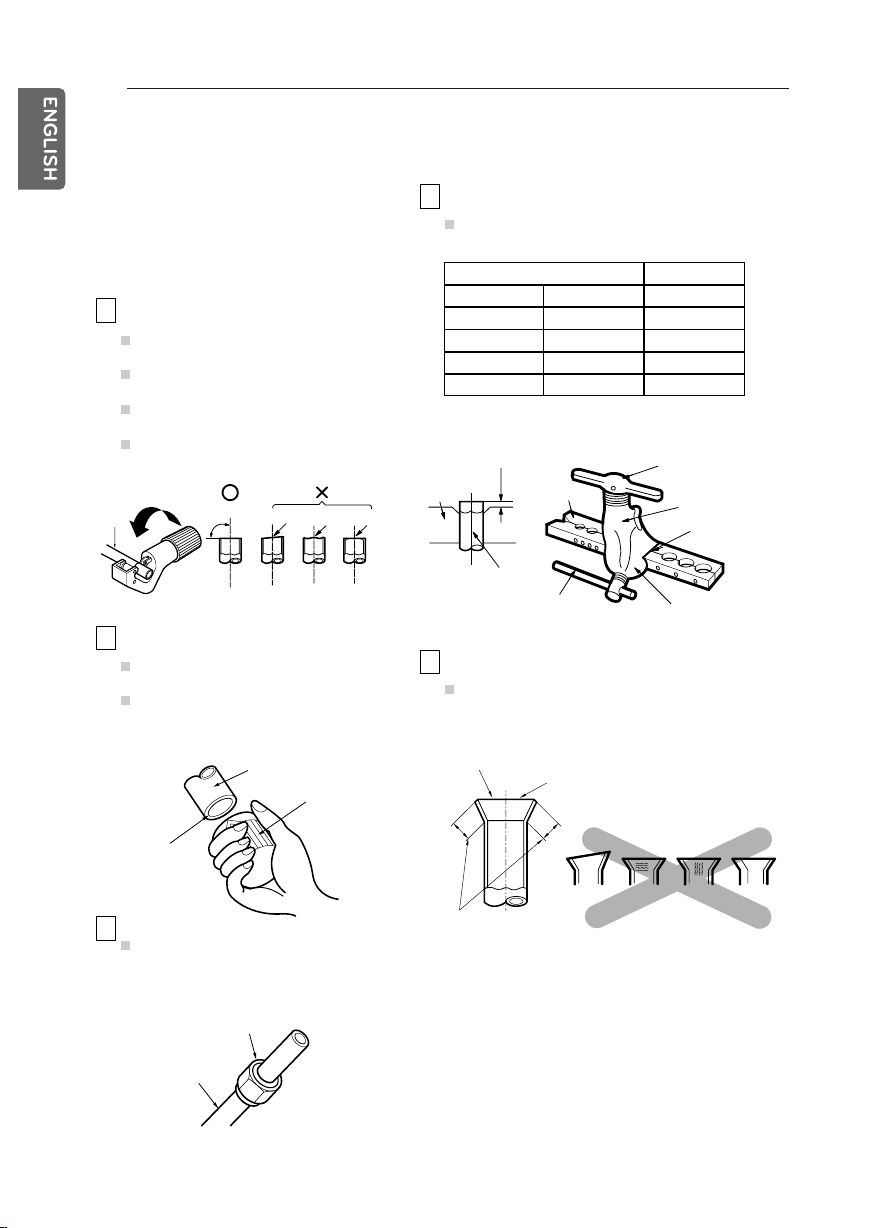

More than 10cm More than 10cm

More

than 60cm

More than 60cm

More than 70cm

Read completely, then follow step by step.

Capacity is based on standard length and maximum

allowance length is on the basis of reliability.

Oil trap should be installed every 5~7 meters.

In case more than 5m

A

Indoor unit

Oil trap

Outdoor unit

A

Indoor unit

Outdoor unit

A

Do not have any heat or steam near the

unit.

Select a place where there are no

obstacles in front of the unit.

Make sure that condensation drainage

can be conveniently routed away.

Do not install near a doorway.

Ensure that the space around the left and

right of the unit is more than 5cm. The

unit should be installed as high on the

wall as possible, allowing a minimum of

5cm from ceiling.

Use a stud finder to locate studs to

prevent unnecessary damage to the wall.

More than 5cm More than 5cm

More than 2.3m More than 5cm

Install the indoor unit on the wall where the height

from the floors more than 2.3 meters.

B

If an awning is built over the unit to

prevent direct sunlight or rain exposure,

make sure that heat radiation from the

condenser is not restricted.

Ensure that the space around the back

and sides is more than 10cm. The front of

the unit should have more than 70cm of

space.

Do not place animals and plants in the

path of the warm air.

Take the air conditioner weight into

account and select a place where noise

and vibration are minimum.

Select a place so that the warm air and

noise from the air conditioner do not

disturb neighbors.

Select the best location

Indoor Unit

CAUTION

Outdoor Unit

If the outdoor unit is installed on a roof structure, be

sure to level the unit. Ensure the roof structure and

anchoring method are adequate for the unit location.

Consult local codes regarding rooftop mounting.

Rooftop Installation

Piping length and elevation

CAUTION

INSTALLATION

8

Capacity

(Btu/h)

18K (60Hz)

24K Cooling

24K, 26K

Cooling & Heat Pump

5/8" 3/8" 3 to 5

Pipe Size

GAS LIQUID

Standard

Length

(m)

1/2" 1/4"

1/4"

3 to 5

3 to 5

20

20

20

20

5/8" 1/4" 3 to 5 20 20

20 20

Max.

length

(m)

A

Additional

Refrigerant

(g/m)

9K, 12K,

18K (50Hz)

9K 3/8"

B