Functions

Indoor Unit

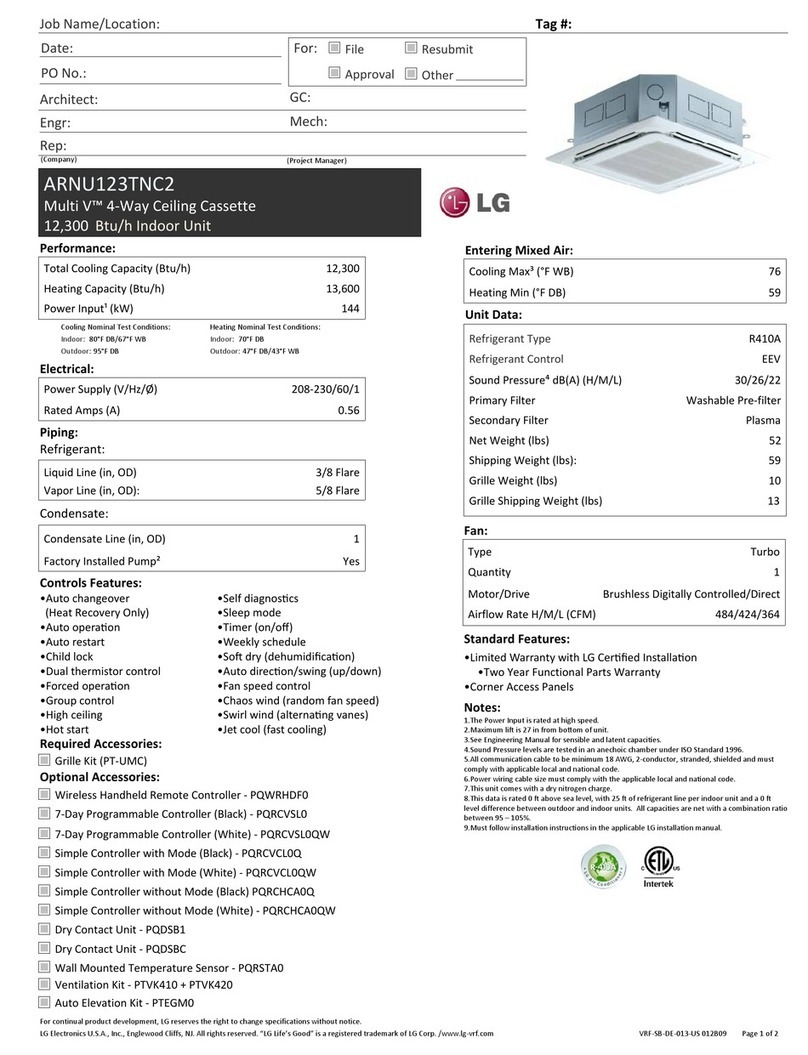

Operation ON/OFF by Remote controller

Sensing the Room Temperature

Room temperature control

Starting Current Control

Time Delay Safety Control

Indoor Fan Speed Control

Soft Dry Operation Mode

Airflow Direction Control

Auto Operation(Auto Change Over)

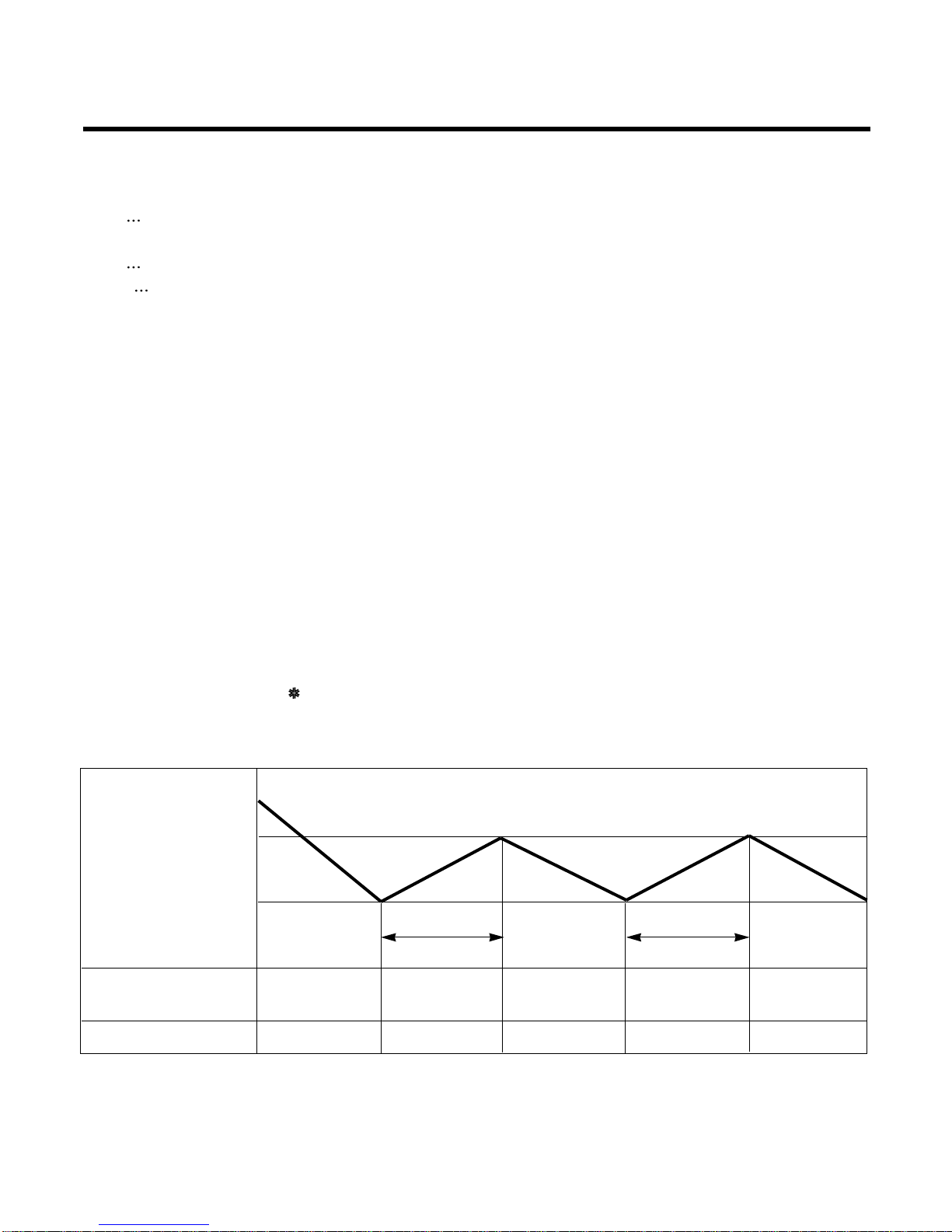

Deice (defrost) control (Heating)

Auto Restart

–3–

Hot-start Control (Heating) • The indoor fan stops until the evaporator piping tempera-

ture will be reached at 28°C.

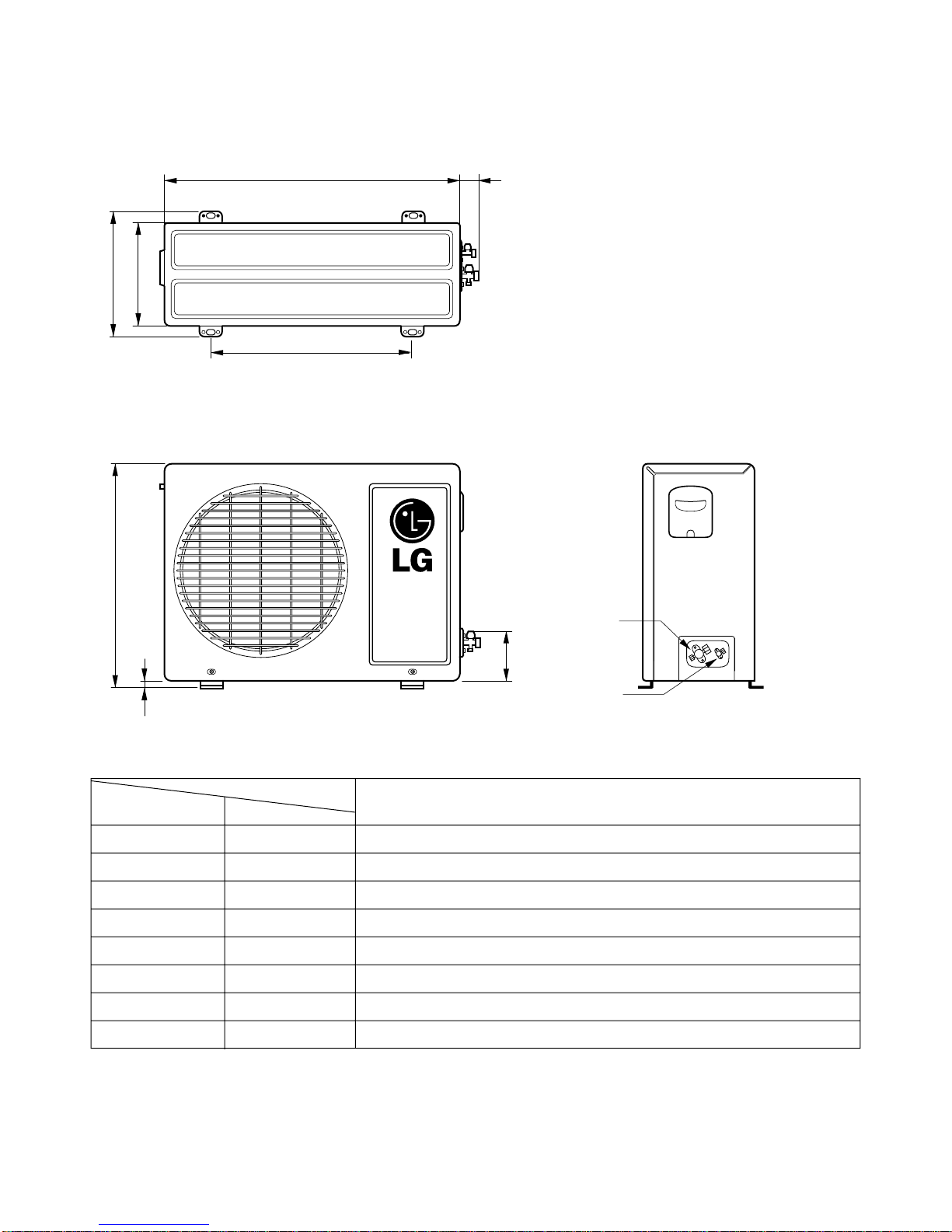

Compact and light design • To install a unit is very convenient size because of smaller

than fextile size. ( 600 x 600 )

Low noise • The most advanced low-noise design.

• The adoption of turbo fan and round type heat exchanger

give the quietest operation.

Long life filter • Long life type(wrinkle) and wastable and anti-bacteria filter

is adopted.

Plasma Air Purifying Filter(2HL Only)

High head height Drain pump • Built-in drain pump automatically drains water.

• A standard drain-head height of up to 700mm is possible.

High-Ceilingcorresponding Function • According to the height of ceiling, the RPM of indoor fan

motor is selectable to increase air reaching distance.

Central Control(Optional) •

It is operating individually or totally by central control function.

Group Control(Optional Wiring) •

Each controller can control 16 units and 8 controllers can connect.

•

It operates maximum 16 units by only one wired remote con-

troller and each unit starts random to prevent overcurrent.

• Room temperature sensor. (Thermistor)

•

Maintains the room temperature in accordance with the Setting Temp.

• Indoor fan is delayed for 5 seconds at the starting.

• Restarting is inhibited for approx. 3 minutes.

• Jet, High, Med, Low

• Intermittent operation of fan at low speed.

• The louver can be set at swing up and down automatically.

• Although the air-conditioner is turned off by a power failure, it is restarted automati-

cally previous operation mode after power supply.

• The setting temperature and desired operation mode are auto-

matically set by fuzzy rule.

• Both the indoor and outdoor fan stops during defrosting.

• Hot start after defrost ends.