—2—

1. PREFACE

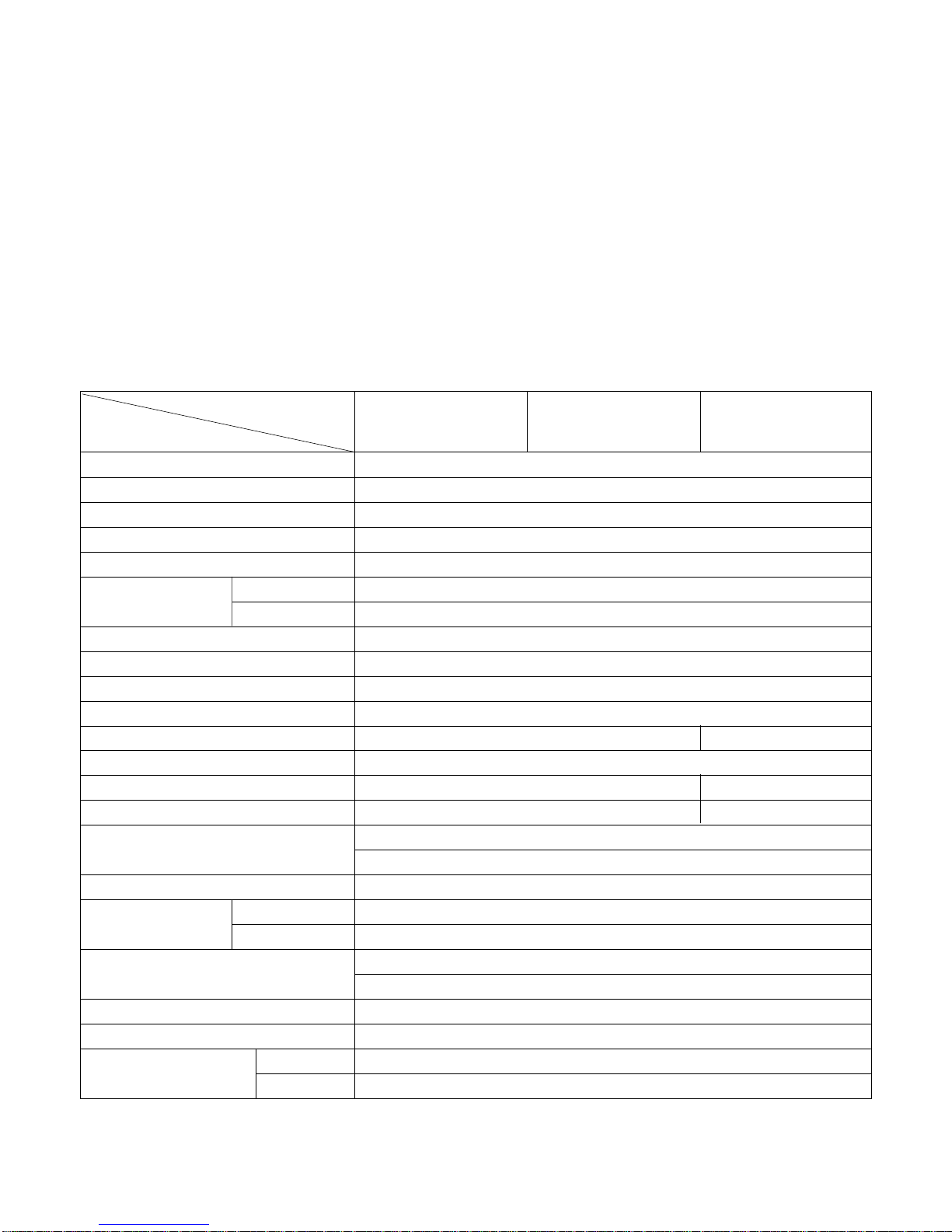

1.1 SAFETY PRECAUTIONS................................................................................................................................3

1.2 INSULATION RESISTANCE TEST.................................................................................................................3

1.3 SPECIFICATIONS...........................................................................................................................................3

1.4 FEATURES .....................................................................................................................................................4

1.5 CONTROL LOCATIONS.................................................................................................................................4

2.

DISASSEMBLY INSTRUCTIONS

2.1 MECHANICAL PARTS....................................................................................................................................6

2.1.1 FRONT GRILLE.....................................................................................................................................6

2.1.2 CABINET................................................................................................................................................6

2.1.3 CONTROL BOX.....................................................................................................................................6

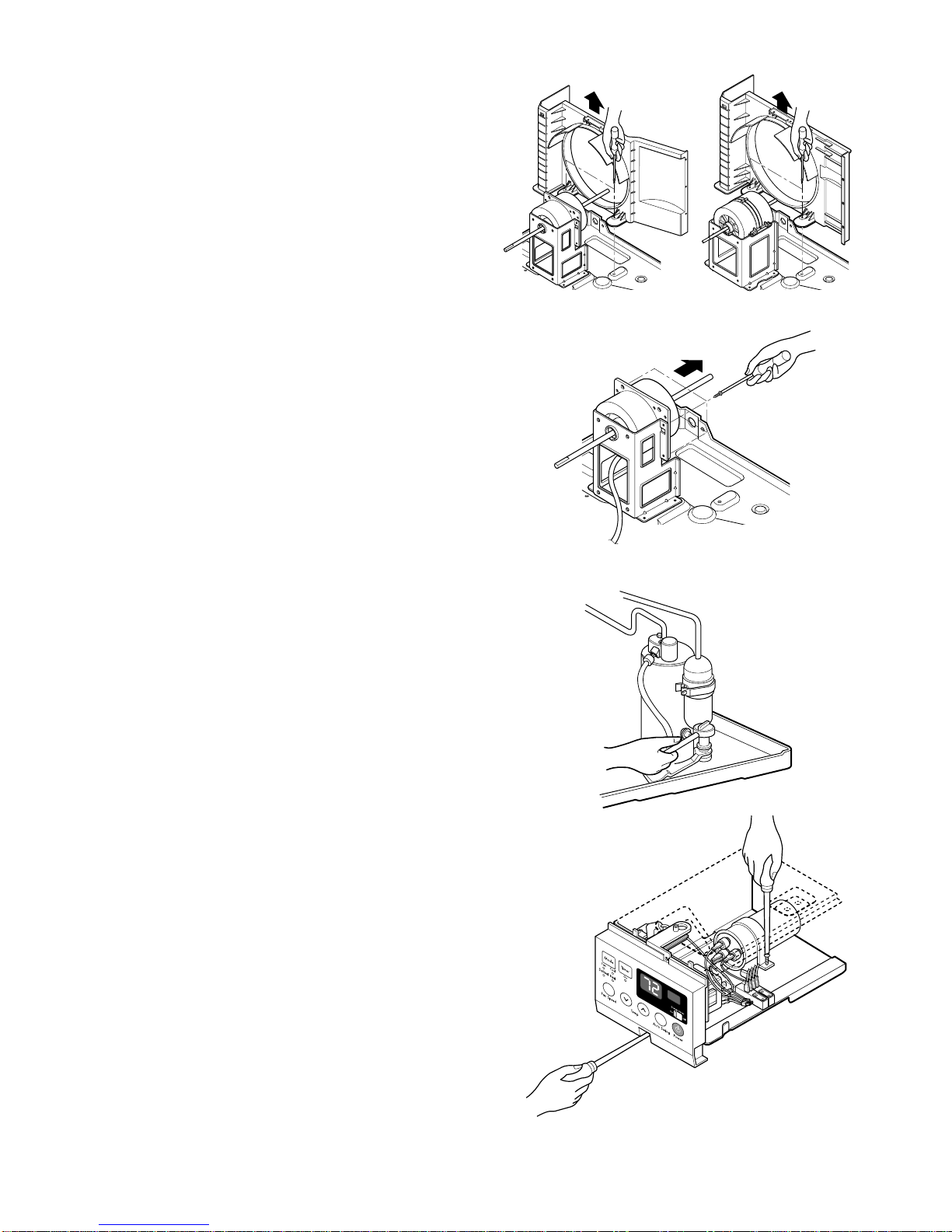

2.2 AIR HANDLING PARTS..................................................................................................................................7

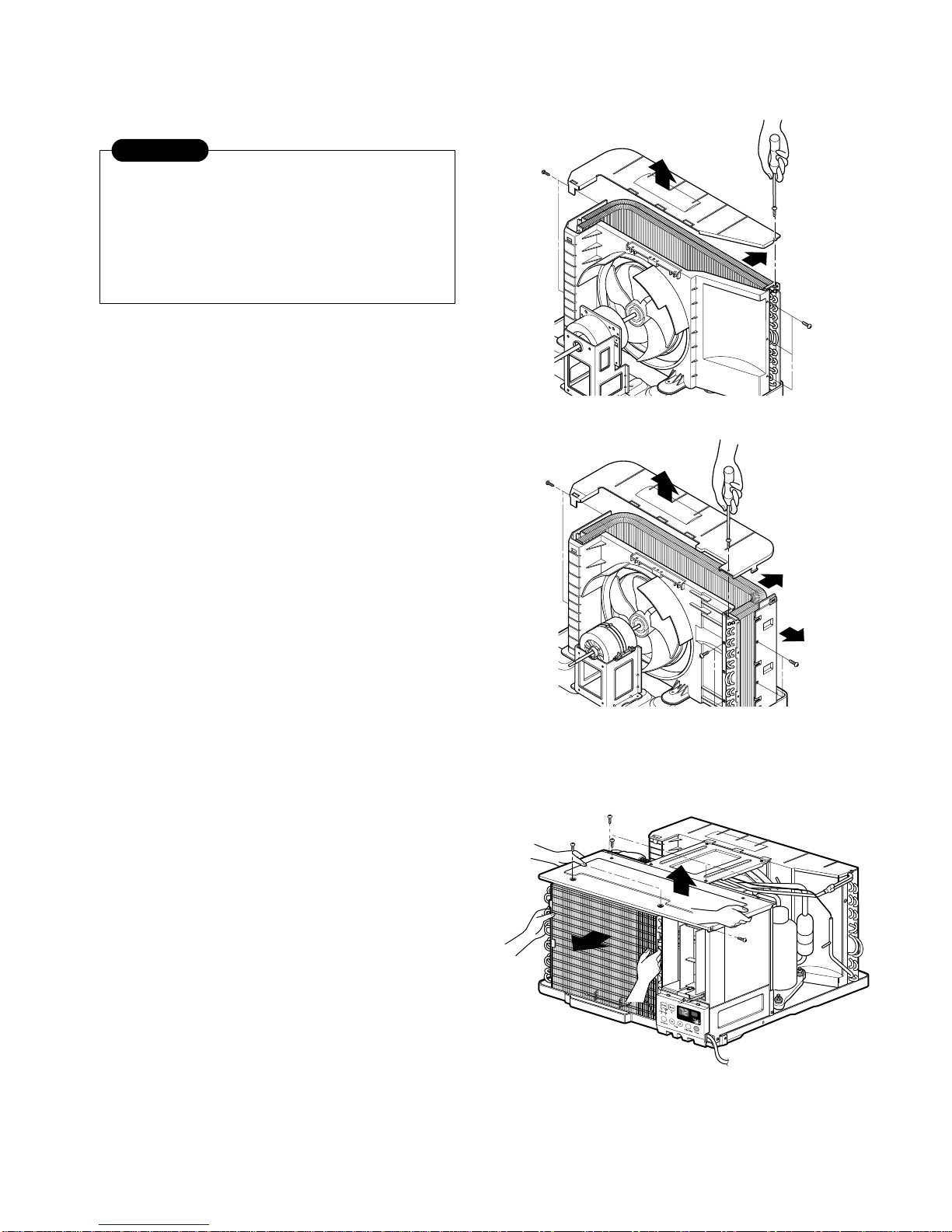

2.2.1 COVER (AT THE TOP)..........................................................................................................................7

2.2.2 BLOWER................................................................................................................................................7

2.2.3 FAN........................................................................................................................................................7

2.2.4 SHROUD................................................................................................................................................8

2.3 ELECTRICAL PARTS .....................................................................................................................................8

2.3.1 MOTOR..................................................................................................................................................8

2.3.2 COMPRESSOR .....................................................................................................................................8

2.3.3 CAPACITOR ..........................................................................................................................................8

2.3.4 POWER CORD......................................................................................................................................9

2.3.5 THERMISTOR........................................................................................................................................9

2.3.6 SYNCHRONOUS MOTOR.....................................................................................................................9

2.4 REFRIGERATION CYCLE............................................................................................................................10

2.4.1 CONDENSER ......................................................................................................................................10

2.4.2 EVAPORATOR ....................................................................................................................................10

2.4.3 CAPILLARY TUBE...............................................................................................................................10

3.

INSTALLATION

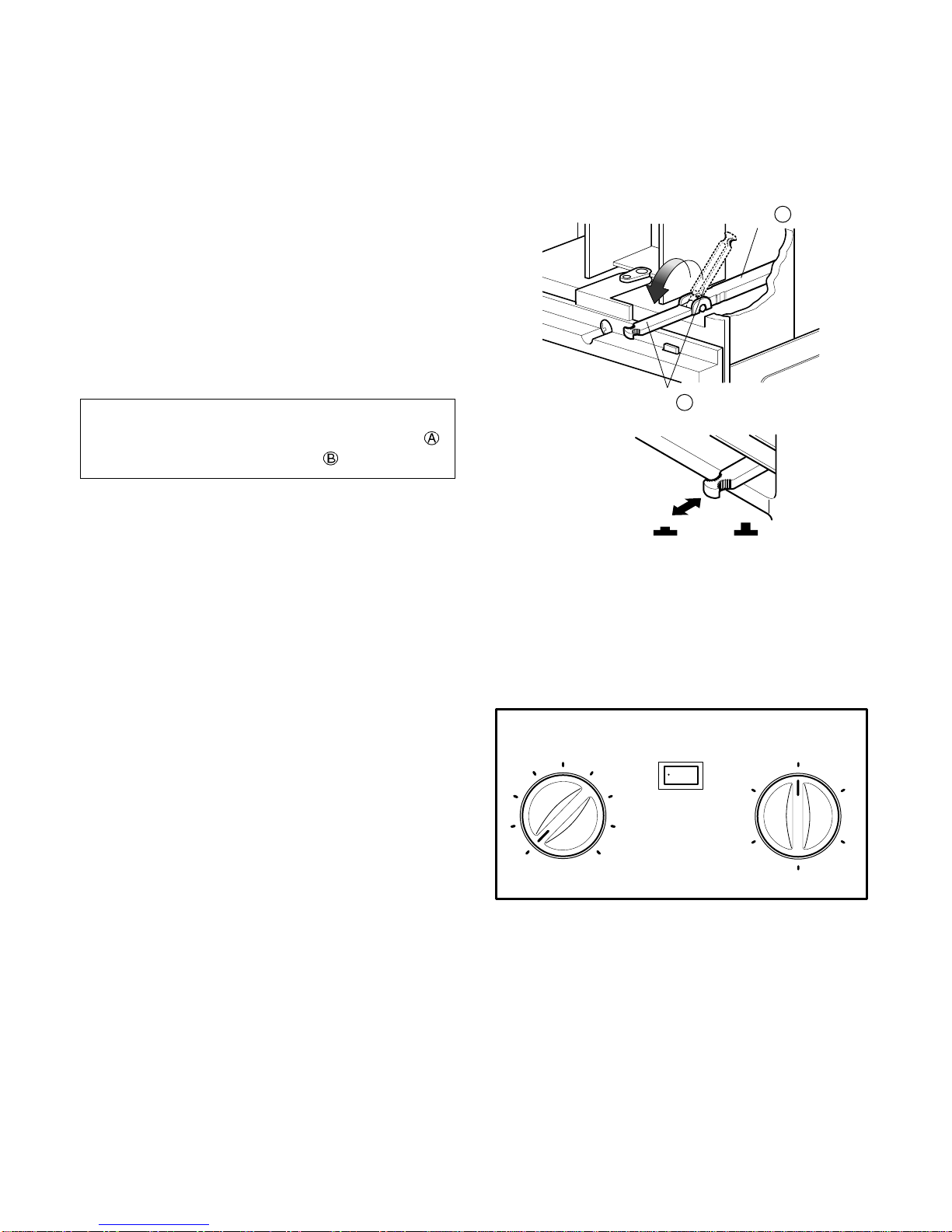

3.1 HOW TO INSTALL THE UNIT.......................................................................................................................13

3.2

HOW TO USE THE REVERSIBLE INLET GRILLE

..................................................................................................................

13

3.3 WINDOW REQUIREMENTS.........................................................................................................................14

3.4 INSTALLATION KITS CONTENTS...............................................................................................................14

3.5 SUGGESTED TOOL REQUIREMENTS.......................................................................................................15

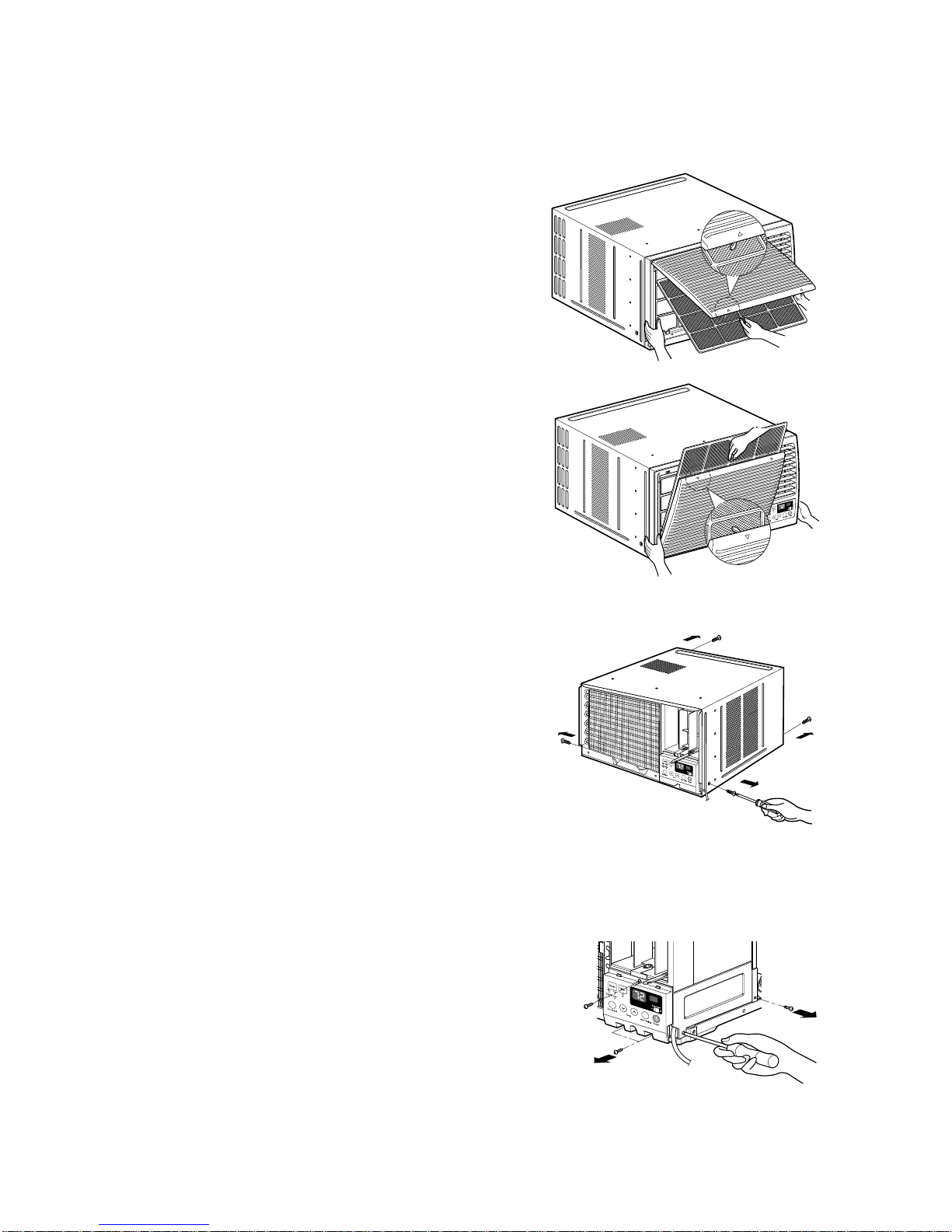

3.6 CABINET INSTALLATION ............................................................................................................................16

4.

TROUBLESHOOTING GUIDE

4.1 OUTSIDE DIMENSIONS...............................................................................................................................18

4.2 PIPING SYSTEM...........................................................................................................................................18

4.3 TROUBLESHOOTING GUIDE......................................................................................................................19

5. SCHEMATIC DIAGRAM

5.1 CIRCUIT DIAGRAM......................................................................................................................................28

5.2 ELECTRONIC CONTROL DEVICE ..............................................................................................................29

5.3

COMPONENTS LOCATION(FOR MAIN P.C.B ASM

).......................................................................................................30

5.4

COMPONENTS LOCATION(FOR DISPLAY P.C.B ASM)

.......................................................................................................30

6. EXPLODED VIEW..................................................................................................................................31

7. REPLACEMENT PARTS LIST........................................................................................................32

CONTENTS