2

ENGLISH

TIPS FOR SAVING ENERGY

Here are some tips that will help you minimize the power consumption

when you use the air conditioner. You can use your air conditioner

more efficiently by referring to the instructions below:

IMPORTANT SAFETY

INSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USING THE

APPLIANCE.

Always comply with the following precautions to avoid dangerous

situations and ensure peak performance of your product.

WARNING

It can result in serious injury or death when the directions are ignored.

CAUTION

It can result in minor injury or product damage when the directions are

ignored.

WARNING

• Installation or repairs made by unqualified persons can result in

hazards to you and others. Installation of all field wiring and

components MUST conform with local building codes or, in the

absence of local codes, with the National Electrical Code 70 and the

National Building Construction and Safety Code or Canadian

Electrical code and National Building Code of Canada.

• The information contained in the manual is intended for use by a

qualified service technician familiar with safety procedures and

equipped with the proper tools and test instruments.

• Failure to carefully read and follow all instructions in this manual can

result in equipment malfunction, property damage, personal injury

and/or death.

Installation

• Have all electric work done by a licensed electrician according to

"Electric Facility Engineering Standard" and "Interior Wire

Regulations" and the instructions given in this manual and always

use a special circuit.

- If the power source capacity is inadequate or electric work is

performed improperly, electric shock or fire may result.

• Ask the dealer or an authorized technician to install the air

conditioner.

- Improper installation by the user may result in water leakage,

electric shock, or fire.

• Always ground the product.

- There is risk of fire or electric shock.

• Always intstall a dedicated circuit and breaker.

- Improper wiring or installation may cause fire or electric shock.

• For re-installation of the installed product, always contact a dealer

or an Authorized Service Center.

- There is risk of fire, electric shock, explosion, or injury.

• Do not install, remove, or re-install the unit by yourself (customer).

- There is risk of fire, electric shock, explosion, or injury.

• Do not store or use flammable gas or combustibles near the air

conditioner.

- There is risk of fire or failure of product.

• Use the correctly rated breaker or fuse.

- There is risk of fire or electric shock.

• Prepare for strong wind or earthquake and install the unit at the

specified place.

- Improper installation may cause the unit to topple and result in

injury.

• Do not install the product on a defective installation stand.

- It may cause injury, accident, or damage to the product.

• Use a vacuum pump or Inert(nitrogen) gas when doing leakage test

or air purge. Do not compress air or Oxygen and do not use

Flammable gases. Otherwise, it may cause fire or explosion.

- There is the risk of death, injury, fire or explosion.

• When installing and moving the air conditioner to another site, do

not charge it with a different refrigerant from the refrigerant

specified on the unit.

- If a different refrigerant or air is mixed with the original refrigerant,

the refrigerant cycle may malfunction and the unit may be

damaged.

• Do not reconstruct to change the settings of the protection devices.

- If the pressure switch, thermal switch, or other protection device

is shorted and operated forcibly, or parts other than those

specified by LGE are used, fire or explosion may result.

• Ventilate before operating air conditioner when gas leaked out.

- It may cause explosion, fire, and burn.

• Securely install the cover of control box and the panel.

- If the cover and panel are not installed securely, dust or water may

enter the outdoor unit and fire or electric shock may result.

• If the air conditioner is installed in a small room, measures must be

taken to prevent the refrigerant concentration from exceeding the

safety limit when the refrigerant leaks.

- Consult the dealer regarding the appropriate measures to prevent

the safety limit from being exceeded. Should the refrigerant leak

and cause the safety limit to be exceeded, harzards due to lack of

oxygen in the room could result.

Operation

• Do not damage or use an unspecified power cord.

- There is risk of fire, electric shock, explosion, or injury.

• Use a dedicated outlet for this appliance.

- There is risk of fire or electrical shock.

• Be cautious that water could not enter the product.

- There is risk of fire, electric shock, or product damage.

• Do not touch the power switch with wet hands.

- There is risk of fire, electric shock, explosion, or injury.

• When the product is soaked (flooded or submerged), contact an

Authorized Service Center.

- There is risk of fire or electric shock.

• Be cautious not to touch the sharp edges when installing.

- It may cause injury.

• Take care to ensure that nobody could step on or fall onto the

outdoor unit.

- This could result in personal injury and product damage.

!

!

!

• Do not cool excessively indoors. This may be harmful for your

health and may consume more electricity.

• Block sunlight with blinds or curtains while you are operating the

air conditioner.

• Keep doors or windows closed tightly while you are operating the

air conditioner.

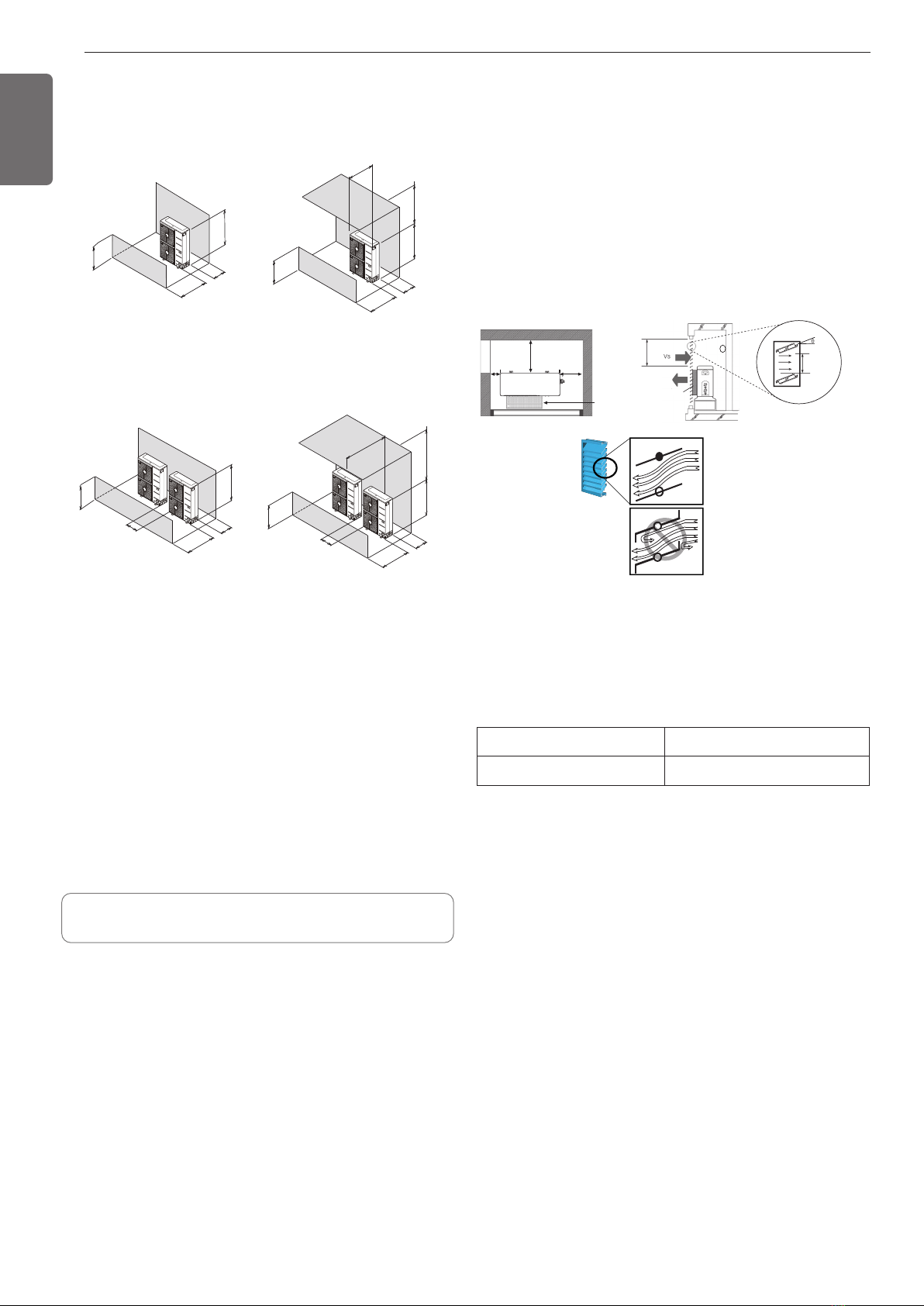

• Adjust the direction of the air flow vertically or horizontally to

circulate indoor air.

• Speed up the fan to cool or warm indoor air quickly, in a short

period of time.

• Open windows regularly for ventilation as the indoor air quality

may deteriorate if the air conditioner is used for many hours.

• Clean the air filter once every 2 weeks. Dust and impurities

collected in the air filter may block the air flow or weaken the

cooling / dehumidifying functions.

For your records

Staple your receipt to this page in case you need it to prove the date

of purchase or for warranty purposes. Write the model number and

the serial number here:

Model number :

Serial number :

You can find them on a label on the side of each unit.

Dealer’s name :

Date of purchase :