8

Lifa Air Oy Ltd. •Vellamonkatu 30 B, 00550 Helsinki, Finland • Tel: +358 9 394 858

1. Avoid contamination of the environment

The machine should be kept as clean as possible. When the cable is being pushed back to the drum

it should be cleaned with a cloth. After the work has been completed the brushes and the shell of the

cleaning shaft must be cleaned, before transporting the machine into another location.

2. General Safety

It is forbidden to stay in immediate contact with the machine while it is operating.

3. The safety of the operator

The person/persons who are performing the work should use personal protection: filtered mouth

mask, helmet, earmuffs, goggles,overall, protection shoesand other necessaryprotective equipment

that the task at hand requires.

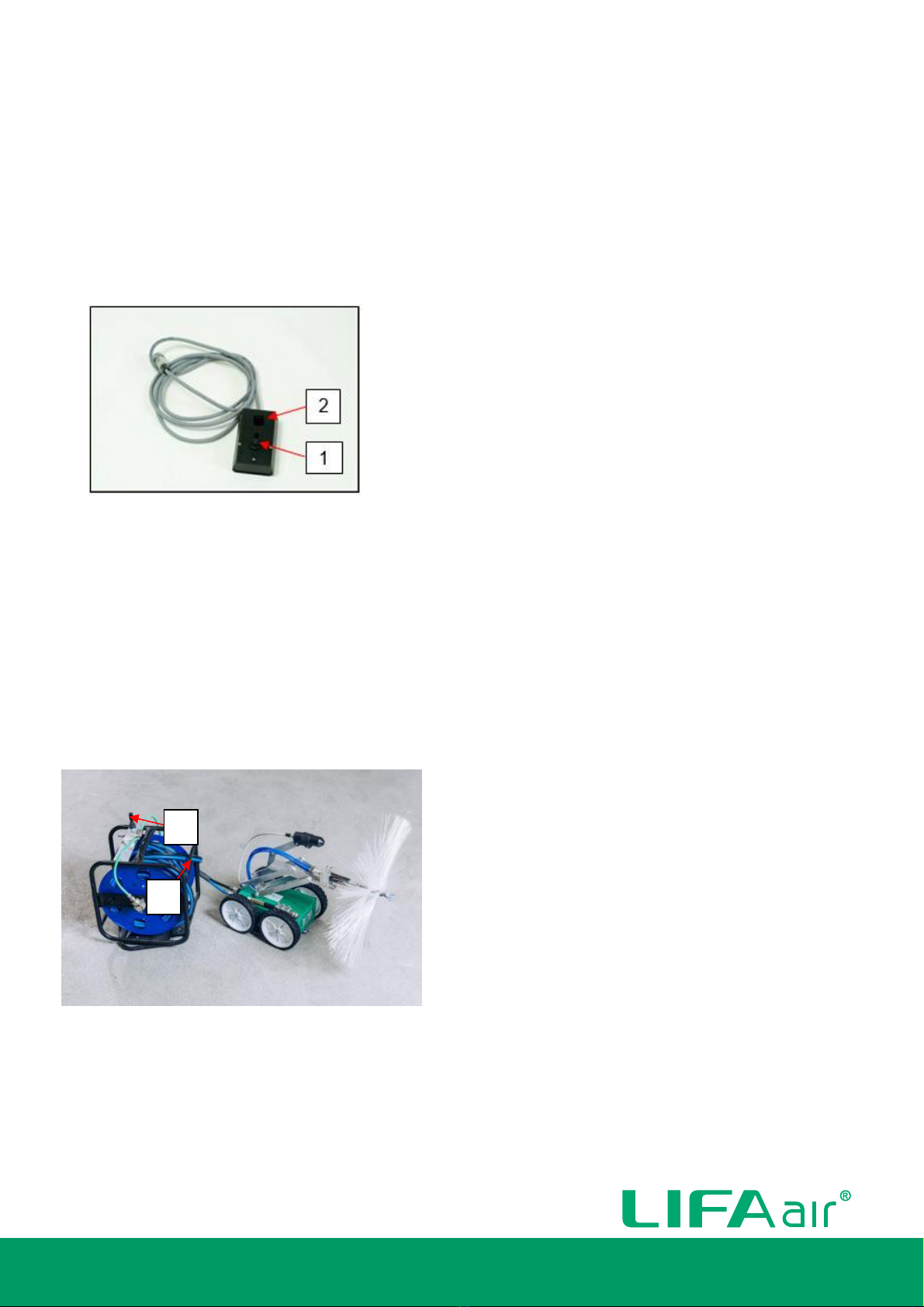

Lifa Duct Control Cleaning Robot has a strong rotating force. Clothes or hair can easily get caught in

the brush and cause damage or accidents. The brush has to be placed always in the ventilation duct

before starting the machine. The machine cannot be used when the brush is outside the ventilation

duct. Because of the great rotating force, the Duct Control Cleaning Robot is recommended to be

used by two persons. One who drives and controls the robot in the duct and another whofeeds/draws

the cables (electrical cable and pneumatic hose).

4. The safety of the working environment

Make sure that the lightning, air conditioning, latter and trestles are sufficient. If the brush generates

static electricity or sparks in the duct do not use these types of brushes in the duct if there are any

flammable liquids, gases, dust or other sensitive substances. Use antistatic brushes and safety

ground by following the special instructions in difficult conditions.

5. Cable (electrical)

Be careful not to damage the cable. If the cable is damaged take immediate contact to your local

distributor. If the cable has been scratched only it can be coated again with a heat shrinkable tube.

During the storage and transportation, the cable has to be reeled. Always make the reeling so that

other end is free so that all the twists/kinks are taken out.

6. Compressed air connection

Make sure that the compressed air feed matches to the information on the CE-plate and the

operating instructions. The connector for brush motor is CEJN 320 series, other analogic

connectors: Rectus 25, Tema 1600 and JWL520/530, all Euro-standard 7.6 (7.4).

The connector for air/liquid jetting is CEJN 221 or Rectus series 21.

7. Sound level

The sound level of Duct Cleaning Robot motor is quite high, still less than 80 dB(A). It is compulsory

to wear earmuffs.