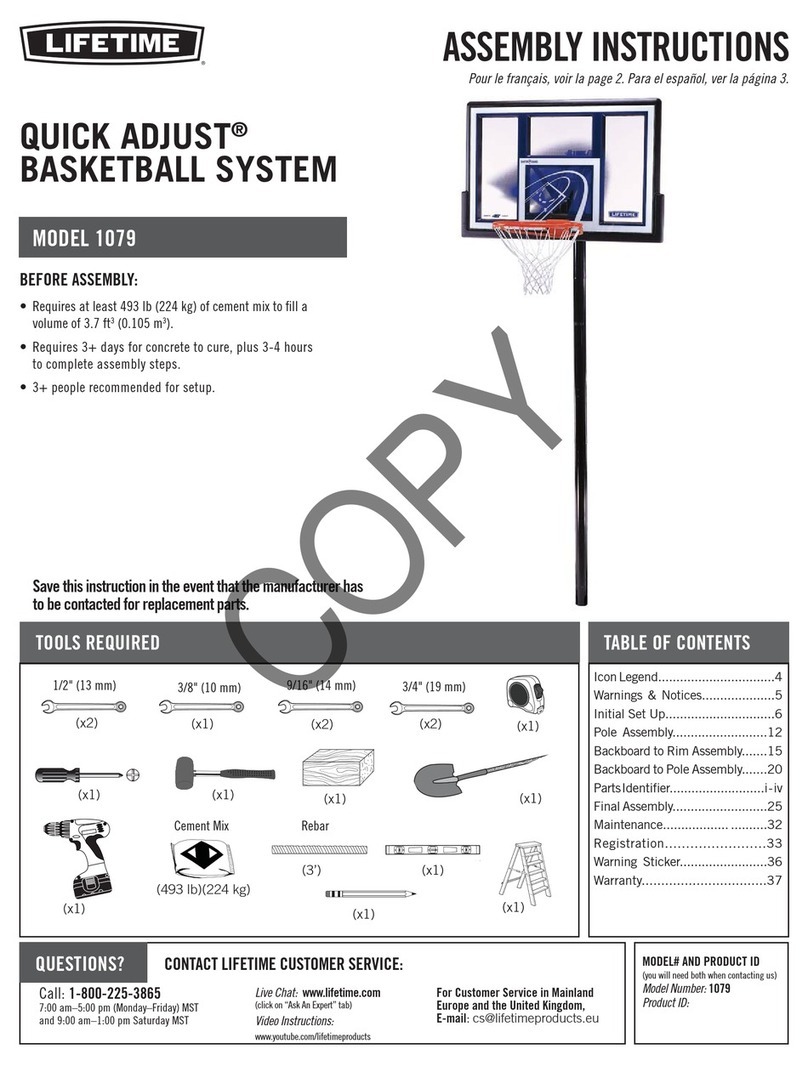

This area is located at the top, left-hand

corner of the page and indicates which tools

and hardware are needed to complete the

assembly steps on a page.

This area is located at the top, right-hand

corner of the page and shows an image of the

product with shaded parts indicating which

section is being assembled.

SEC

#

Note:

!

Refer to the following areas throughout the instructions

to assist in the assembly process:

This area is usually located in the bottom,

left-hand corner of a step and indicates that

special attention is needed to perform a

particular part of a step.

These areas are usually located in the bottom,

right-hand corner of a step and indicate that

damage to the product or serious injury may

occur if the caution or warning is not heeded.

Throughout the Parts & Hardware List, Part

& Hardware Identifiers, and instructions

are three-letter IDs. These IDs are below

the images of the parts and hardware to

help you locate and identify the parts and

hardware during assembly. These IDs are not

necessarily on the parts themselves.

WARNING

ASSEMBLY GUIDES

TOOLS AND HARDWARE REQUIRED FOR THIS PAGE

CAUTION

ADZ (x10)

1/4” x 5/8” Pan-Head Screw

This area is located at the top, left-hand

corner of the page and indicates which tools

and hardware are needed to complete the

assembly steps on a page.

This area is located at the top, right-hand

corner of the page and shows an image of the

product with shaded parts indicating which

section is being assembled.

SEC

#

Note:

!

Refer to the following areas throughout the instructions

to assist in the assembly process:

This area is usually located in the bottom,

left-hand corner of a step and indicates that

special attention is needed to perform a

particular part of a step.

These areas are usually located in the bottom,

right-hand corner of a step and indicate that

damage to the product or serious injury may

occur if the caution or warning is not heeded.

Throughout the Parts & Hardware List, Part

& Hardware Identifiers, and instructions

are three-letter IDs. These IDs are below

the images of the parts and hardware to

help you locate and identify the parts and

hardware during assembly. These IDs are not

necessarily on the parts themselves.

WARNING

ASSEMBLY GUIDES

TOOLS AND HARDWARE REQUIRED FOR THIS PAGE

CAUTION

ADZ (x10)

1/4” x 5/8” Pan-Head Screw