3

Most injuries are caused by misuse and/or not following instructions. Use caution when using this product.

To ensure safety, do not attempt to assemble this product without reading and

FOLLOWINGALLINSTRUCTIONSCAREFULLY#HECKTHEENTIREBOXANDINSIDEALLPACKING

materials for parts and/or additional instruction material. "EFOREBEGINNINGASSEMBLY

identify and inventory all parts and hardware using the parts and hardware lists and

identifiers in this document. Proper and complete assembly, use and supervision

AREESSENTIALFORPROPERORIENTATIONANDTOREDUCETHERISKOFACCIDENTORINJURY!

HIGHPROBABILITYOFSERIOUSINJURYEXISTSIFTHISPRODUCTISNOTINSTALLEDMAINTAINED

and/or operated properly. Failure to comply with any of the warnings in this

INSTRUCTIONMANUALMAYRESULTINSERIOUSPERSONALINJURIESSUCHASCUTSBROKEN

BONESNERVEDAMAGEPARALYSISBRAININJURYORDEATH&AILURETOCOMPLYMAYALSO

result in property damage. Please heed all warnings and cautions.

&!),52%4/&/,,/74(%3%7!2.).'3-!92%35,4).3%2)/53).*529/202/0%249

DAMAGE AND WILL VOID WARRANTY.

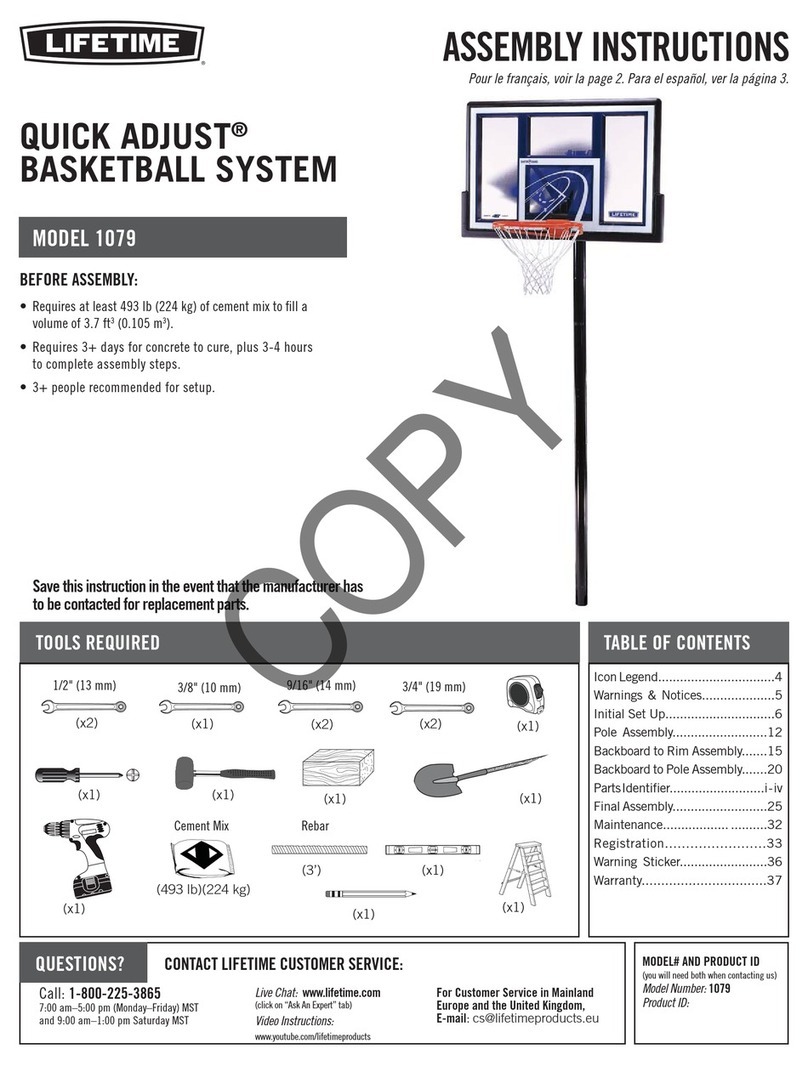

s4HREECAPABLEADULTSARERECOMMENDEDFORTHISOPERATION

s)FUSINGALADDERDURINGASSEMBLYUSEEXTREMECAUTION

s"EFOREDIGGINGCONTACTUTILITYCOMPANYTOLOCATEUNDERGROUNDPOWERCABLESGAS

and water lines. Ensure that there are no overhead power lines within 20 ft. (7m)

radius of Pole location.

SAFETY INSTRUCTIONS

BEFORE BEGINNING ASSEMBLY

Keep the hardware bags and their contents separate. If any parts

are missing, call our Customer Service Department.

Identify and inventory all parts and hardware using the parts and

hardware lists and identifiers in this document.

4ESTlTALL"OLTSBYINSERTINGTHEMINTOTHEIRRESPECTIVEHOLES)F

NECESSARYCAREFULLYSCRAPEAWAYANYEXCESSPOWDERCOATING

buildup from inside the holes. Do not scrape away all of the

POWDERCOATING"AREMETALMAYRUST9OUMAYNEEDTOPOUND

SOME"OLTSINTOPLACEWITHAHAMMERORMALLET