3

Most injuries are caused by misuse and/or not following instructions. Use caution when using this product.

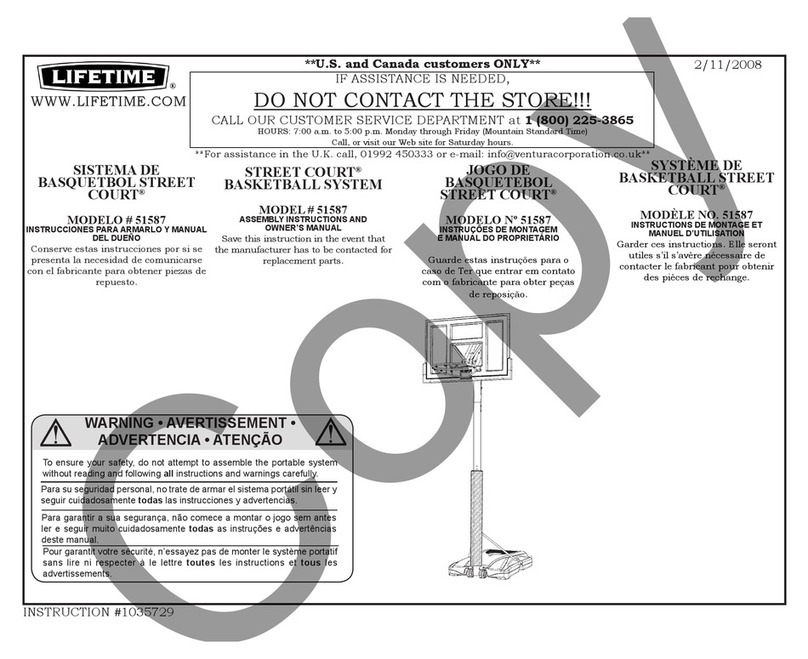

To ensure safety, do not attempt to assemble this product without reading and

following all instructions carefully. Check the entire box and inside all packing

materials for parts and/or additional instruction material. Before beginning assembly,

identify and inventory all parts and hardware using the parts and hardware lists and

identifiers in this document. Proper and complete assembly, use and supervision

are essential for proper orientation and to reduce the risk of accident or injury. A

high probability of serious injury exists if this product is not installed, maintained,

and/or operated properly. Failure to comply with any of the warnings in this

instruction manual may result in serious personal injuries such as cuts, broken

bones, nerve damage, paralysis, brain injury, or death. Failure to comply may also

result in property damage. Please heed all warnings and cautions.

&!),52%4/&/,,/74(%3%7!2.).'3-!92%35,4).3%2)/53).*529/202/0%249

$!-!'%!.$7),,6/)$7!22!.49

s)FUSINGALADDERDURINGASSEMBLYUSEEXTREMECAUTION

s4WOCAPABLEADULTSARERECOMMENDEDFORTHISOPERATION

s#HECKBASEDAILYFORLEAKAGE,EAKSMAYCAUSEPRODUCTTOFALL

s!SSEMBLETHEPOLESECTIONSPROPERLY&AILURETODOSOCOULDCAUSETHEPOLE

sections to separate during play or transport.

SAFETY INSTRUCTIONS

BEFORE BEGINNING ASSEMBLY

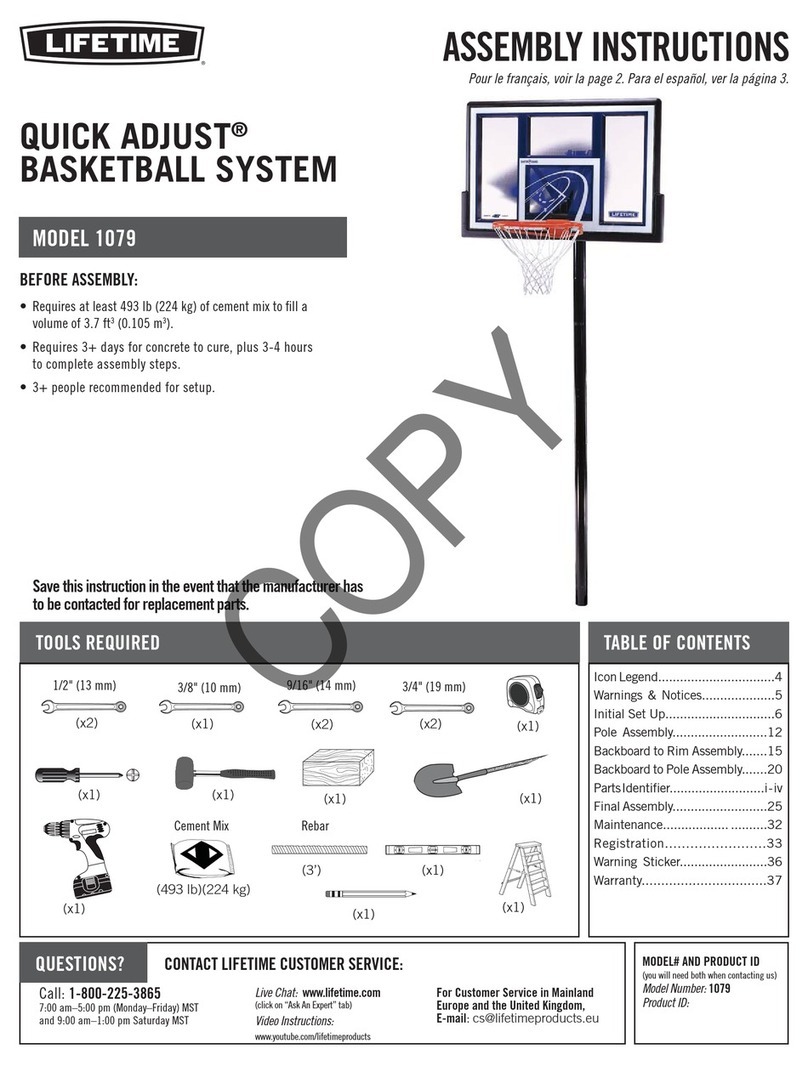

Keep the hardware bags and their contents separate. If any parts

are missing, call our Customer Service Department.

Identify and inventory all parts and hardware using the parts and

hardware lists and identifiers in this document.

Test fit all Bolts by inserting them into their respective holes. If

necessary, carefully scrape away any excess powder coating

buildup from inside the holes. Do not scrape away all of the

powder coating. Bare metal may rust. You may need to pound

some Bolts into place with a hammer or mallet.

Most injuries are caused by misuse and/or not following instructions. Use caution when using this product.

To ensure safety, do not attempt to assemble this product without reading and

following all instructions carefully. Check the entire box and inside all packing

materials for parts and/or additional instruction material. Before beginning assembly,

identify and inventory all parts and hardware using the parts and hardware lists and

identifiers in this document. Proper and complete assembly, use and supervision

are essential for proper orientation and to reduce the risk of accident or injury. A

high probability of serious injury exists if this product is not installed, maintained,

and/or operated properly. Failure to comply with any of the warnings in this

instruction manual may result in serious personal injuries such as cuts, broken

bones, nerve damage, paralysis, brain injury, or death. Failure to comply may also

result in property damage. Please heed all warnings and cautions.

&!),52%4/&/,,/74(%3%7!2.).'3-!92%35,4).3%2)/53).*529/202/0%249

$!-!'%!.$7),,6/)$7!22!.49

s)FUSINGALADDERDURINGASSEMBLYUSEEXTREMECAUTION

s4WOCAPABLEADULTSARERECOMMENDEDFORTHISOPERATION

s#HECKBASEDAILYFORLEAKAGE,EAKSMAYCAUSEPRODUCTTOFALL

s!SSEMBLETHEPOLESECTIONSPROPERLY&AILURETODOSOCOULDCAUSETHEPOLE

sections to separate during play or transport.

SAFETY INSTRUCTIONS

BEFORE BEGINNING ASSEMBLY

Keep the hardware bags and their contents separate. If any parts

are missing, call our Customer Service Department.

Identify and inventory all parts and hardware using the parts and

hardware lists and identifiers in this document.

Test fit all Bolts by inserting them into their respective holes. If

necessary, carefully scrape away any excess powder coating

buildup from inside the holes. Do not scrape away all of the

powder coating. Bare metal may rust. You may need to pound

some Bolts into place with a hammer or mallet.