Pro King 9XLT

Jan. 2022

8

Installation Instructions

3.1 Preparation before installation

3.1.1 Installation tools and lifting equipment

Two open-end wrenches (17-19),

20 inch adjustable wrenches

One 5mm screwdriver

12L of 46# anti-wear hydraulic oil

One 1 ton capacity lifting equipment

One measuring tape, one chalk

3.1.2 Check against Packing List – Attachment 1 (Packing List of Entire Machine)

Unpack the package and check whether the parts are complete against Attachment 1

(Packing List of Entire Machine). Contact your dealer or the manufacturer immediately

once any omission is detected. The dealer will not take any responsibility for and solve any

problem for free, if any missing part is detected but the machine is still installed with the

missing part unresolved.

3.1.3 Requirements for ground

This lift must be installed on flat and solid concrete ground, with the concrete strength

being above 3000psi and the thickness being 200mm or greater, Within whole area the

flatness error being less than 5mm. Newly poured concrete shall be cured for more than 20

days in dry condition without direct exposure to sunshine.

3.2 Cautions for installation

3.2.1 Conduits and electric wires must be connected correctly, to avoid oil leakage and

loosening of wires.

3.2.2 All the bolts must be tightened.

3.2.3 No car shall be put on the machine during trial run.

3.3 Installation procedures

Step 1: selection of a proper installation site

This lift shall be installed indoor. It shall be installed on solid concrete ground, not on any

expansion joint of cement ground. It must not be installed on the second or higher floor, without

permission of relevant building personnel.

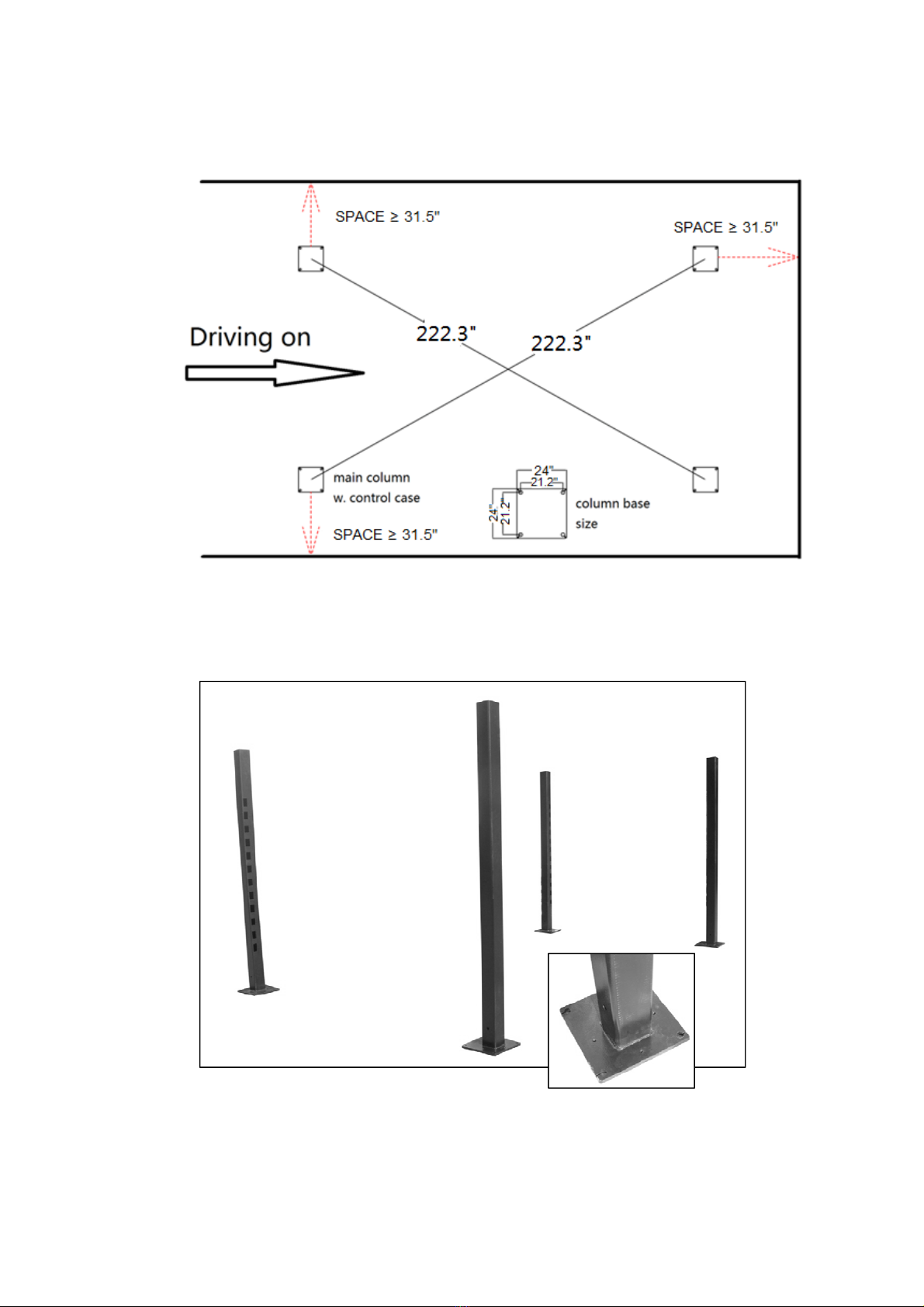

Step 2: determination of layout

When installation site is selected, mark positions of four columns with a measuring tape and a

chalk and make sure two diagonal lines equal each other. See the following drawing (Fig.10)

The space from column to wall must be kept as more than 800mm for safe walking.