Table of contents

1. Foreword...................................................................................................................................................4

2. EU Declaration of Conformity.............................................................................................................5

3. Factory Acceptance Test (FAT)...........................................................................................................6

4. Terms of use.............................................................................................................................................7

5. Technical specifications..........................................................................................................................8

6. Safety instructions...................................................................................................................................9

6.1 Installation and maintenance ...........................................................................................................9

6.2 Unintended movements of the lift.................................................................................................9

6.3 Operating conditions ........................................................................................................................9

6.4 Overloading the lift............................................................................................................................9

6.5 Personal safety....................................................................................................................................9

6.6 Anti-crushing .....................................................................................................................................10

6.7 Avoid personal injury ......................................................................................................................10

6.8 Safety barriers...................................................................................................................................10

6.9 Automatic door................................................................................................................................11

6.10 Unlocking the door in an emergency..........................................................................................11

6.11 Emergency evacuation in the event of a malfunction..............................................................11

6.12 Handling..............................................................................................................................................11

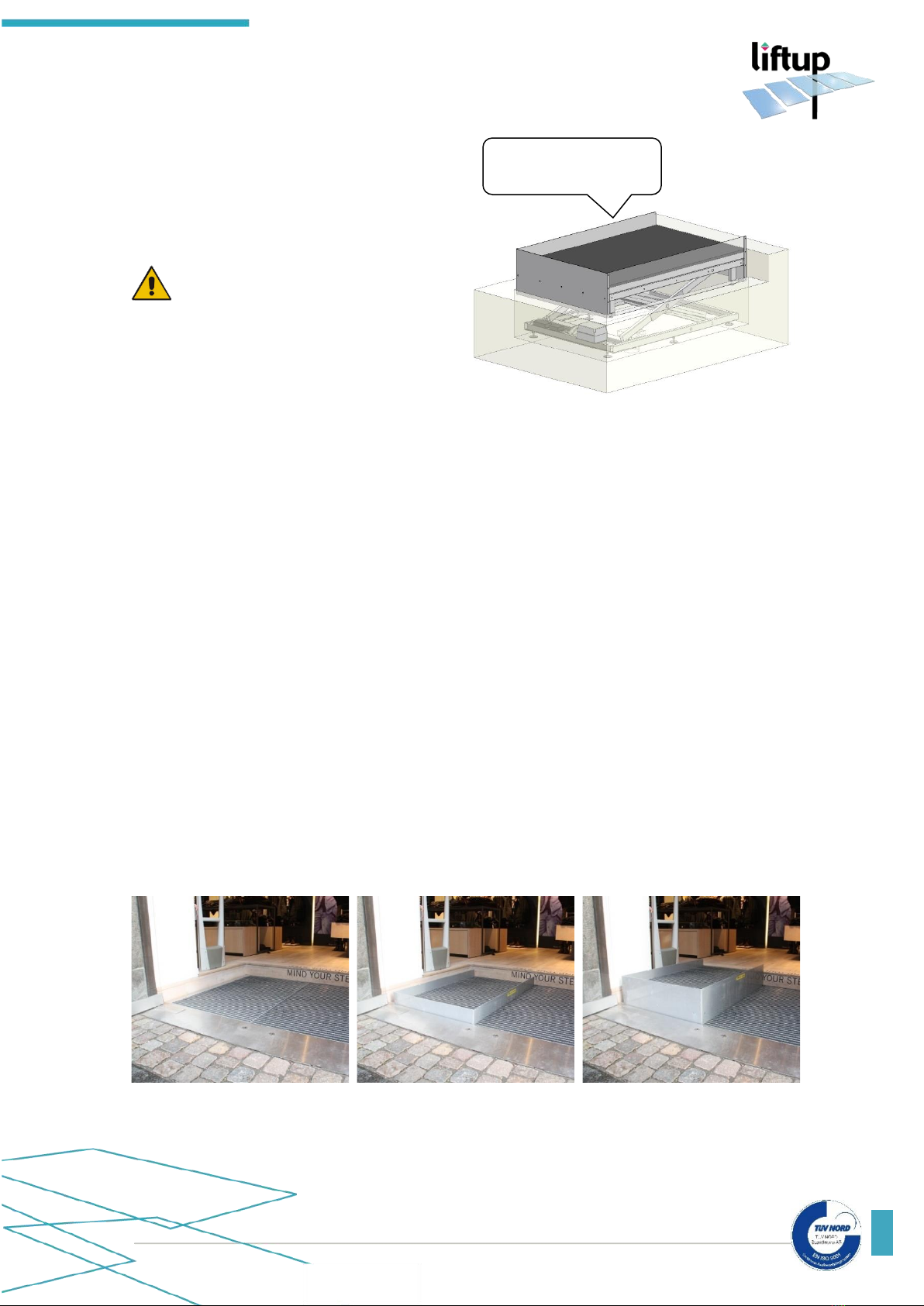

7. Function description.............................................................................................................................12

8. Assembly .................................................................................................................................................12

9. Start-up....................................................................................................................................................12

10. Operation................................................................................................................................................13

10.1 Everyday use......................................................................................................................................13

10.2 Operation of the HDN lift from UPPER level..........................................................................13

10.3 Operation of the HDN lift from LOWER level .......................................................................13

10.4 Operating the HDN lift when the user is on the lift ..............................................................14

10.5 Emergency stop ................................................................................................................................14

10.6 Key switch .........................................................................................................................................14

11. Operation................................................................................................................................................14

12. Maintenance............................................................................................................................................15

12.1 Cleaning..............................................................................................................................................15

12.2 Mechanical maintenance.................................................................................................................15

12.3 Replacement of battery in call stations/remote control ........................................................15

13. Pairing transmitter and receiver ........................................................................................................17