Z 10/15/20Contents

3www.zepro.com

Contents

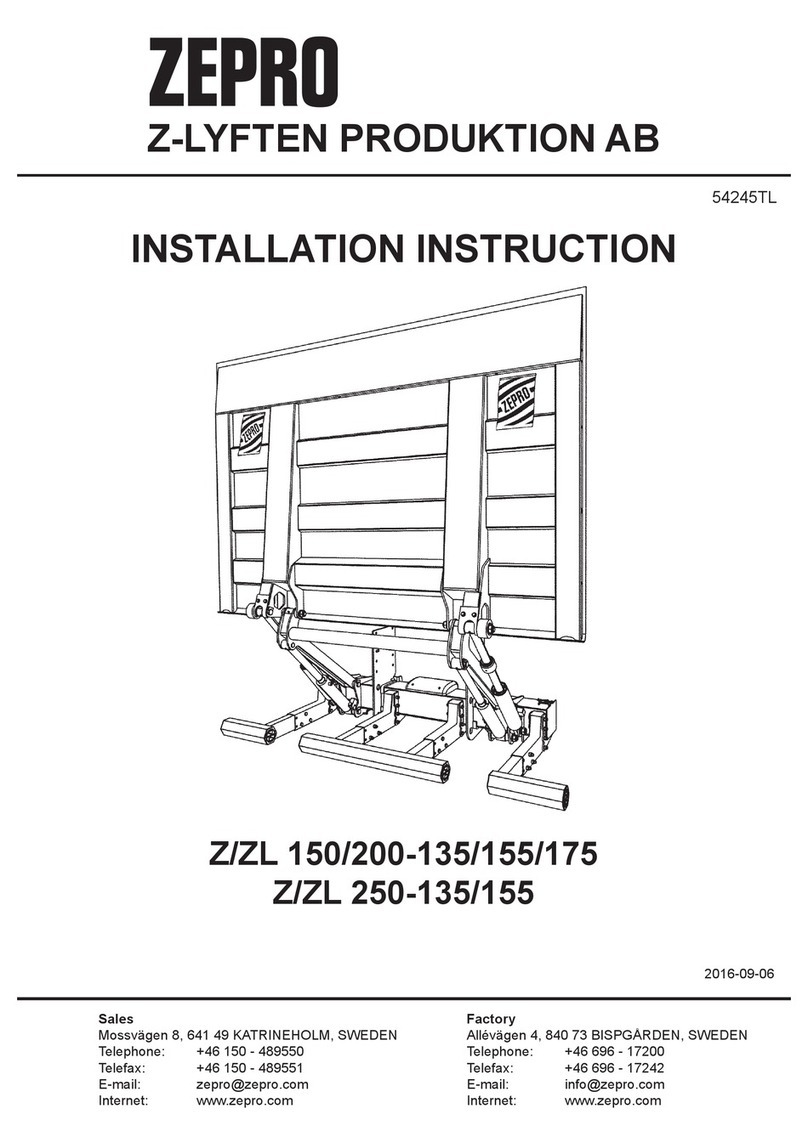

1 Introduction ...................................................................................................... 5

1.1 Important ................................................................................................ 5

1.2 CE marking............................................................................................. 6

1.3 Product approval ................................................................................... 6

1.4 Hydraulic oil ............................................................................................ 6

1.5 Guarantee............................................................................................... 6

1.6 Identication ........................................................................................... 7

2 Safety rules ....................................................................................................... 8

2.1 Repainting .............................................................................................. 8

2.2 Transport plug......................................................................................... 9

2.3 Moving parts - free movement................................................................ 9

1.1 Third-party equipment must not be attached........................................ 10

2.4 Installation ............................................................................................ 10

3 Installation workflow...................................................................................... 11

3.1 Installing the support frame .................................................................. 11

3.2 Electrical connections........................................................................... 11

3.3 Installing the platform ........................................................................... 11

3.4 Installing the cylinders .......................................................................... 11

3.5 Attaching stickers ................................................................................. 11

4 Calculating the installed dimensions ........................................................... 12

4.1 C dimension ......................................................................................... 12

4.2 D dimension ......................................................................................... 12

4.3 A dimension .......................................................................................... 12

4.4 H dimension.......................................................................................... 12

5 Rear member cut-outs ................................................................................... 15

6 Installation ..................................................................................................... 16

6.1 Support frame....................................................................................... 16

6.2 Control power cable.............................................................................. 19

6.3 Controllers ............................................................................................ 20

6.4 Warning lighting/foot controls ............................................................... 21

6.5 Main power cable ................................................................................. 23

6.6 Installation of main fuse on vehicles without connection point ............. 24

6.7 Underrun protection.............................................................................. 25

6.8 Armstops .............................................................................................. 28

6.9 Sealing strip (horizontal)....................................................................... 28

6.10 Sealing strip (vertical) ........................................................................... 28

6.11 Platform ................................................................................................ 29

6.12 Purging the cylinders ............................................................................ 33

6.13 Transport lock....................................................................................... 33

7 Hydraulic unit ................................................................................................. 34