www.lika.biz Lika Electronic

Tel. +39 0445 806600 Via S.Lorenzo, 25

Fax +39 0445 806699 36010 Carrè (VI) - Italy

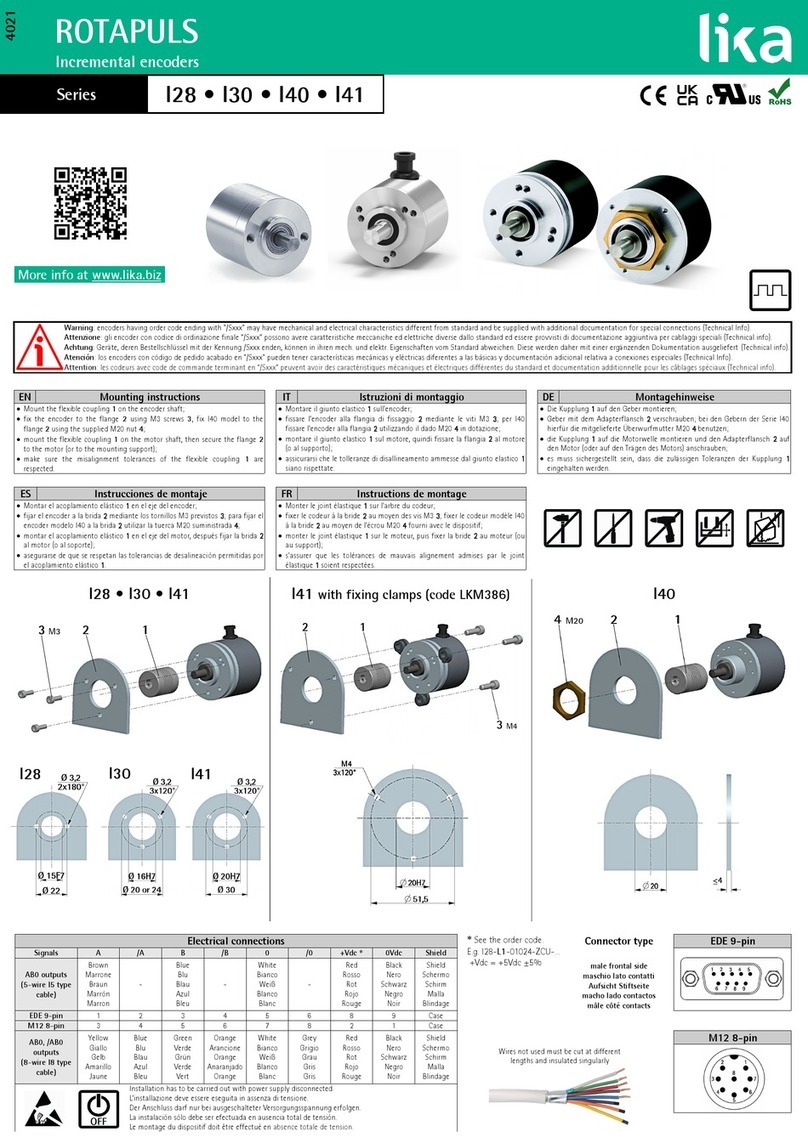

Electrical connections M12 8 pin type connector

Si nals M12 8 pin M8 cable Cavo M8 Kabel M8 Cable M8 Câble M8 male frontal side

maschio lato contatti

Aufsicht Stiftseite

macho lado contactos

mâle côté contacts

0Vdc 1 Black Nero Schwarz Negro Noir

+5Vdc ±5% 2 Red Rosso Rot Rojo Rouge

Clock IN + / MA + 3 Yellow Giallo Gelb Amarillo Jaune

Clock IN - / MA - 4 Blue Blu Blau Azul Bleu

Data OUT + / SLO + 5 Green Verde Grün Verde Vert

Data OUT - / SLO - 6 Orange Arancione Orange Anaranjado Orange

Zero settin 7 White Bianco Weiß Blanco Blanc M8 cable specifications

not connected 8 Grey Grigio Grau Gris Gris

Shieldin Case Shield Calza Schirm Malla Blindage Model:

Wires:

Shield:

External diameter:

Impedance:

Min bend radius:

LIKA HI-FLEX M8 type cable

6 x 0 14 mm2 + 2 x 0 22 mm2

Tinned copper braid

5 3 mm ÷ 5 6 mm

6 x 148 /Km, 2 x 90 /Km

Ø x 7 5

Installation has to be carried out with power supply disconnected

L’installazione deve essere eseguita in assenza di tensione

Der Anschluss darf nur bei ausgeschalteter Versorgungsspannung erfolgen

La instalación sólo debe ser efectuada en ausencia total de tensión

Le montage du dispositif doit être effectué en absence totale de tension

Safety EN IT Avvertenze

Always adhere to the professional safety and accident prevention regulations applicable to your country during device installation

and operation;

installation has to be carried out by qualified personnel only, with power supply disconnected and stationary mechanical parts;

the encoder must be used only for the purpose appropriate to its design: use for purposes other than those for which it has been

designed could result in serious personal and/or the environment damage;

high current, voltage and moving mechanical parts can cause serious or fatal injury;

warning ! Do not use in explosive or flammable areas;

failure to comply with these precautions or with specific warnings elsewhere in this manual violates safety standards of design,

manufacture, and intended use of the equipment;

Lika Electronic assumes no liability for the customer's failure to comply with these requirements

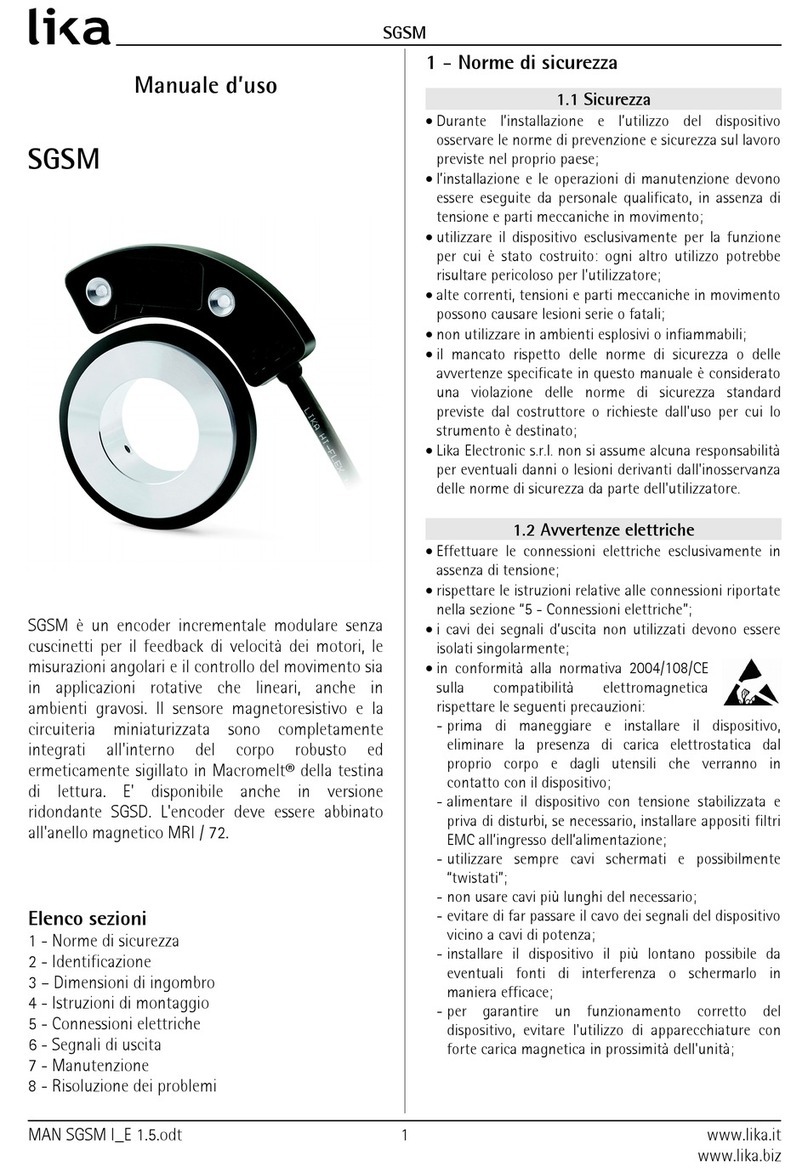

Durante l’installazione e l’utilizzo del dispositivo osservare le norme di prevenzione e sicurezza sul lavoro previste nel proprio

paese;

l’installazione deve essere eseguita da personale qualificato, in assenza di tensione e parti meccaniche in movimento;

utilizzare il dispositivo esclusivamente per la funzione per cui è stato costruito: ogni altro utilizzo potrebbe risultare pericoloso per

l'utilizzatore;

alte correnti, tensioni e parti meccaniche in movimento possono causare lesioni serie o fatali;

non utilizzare in ambienti esplosivi o infiammabili;

il mancato rispetto delle norme di sicurezza o delle avvertenze specificate in questo manuale è considerato una violazione delle

norme di sicurezza standard previste dal costruttore o richieste dall'uso per cui lo strumento è destinato;

Lika Electronic non si assume alcuna responsabilità per eventuali danni o lesioni derivanti dall'inosservanza delle norme di

sicurezza da parte dell'utilizzatore

Electrical safety Avvertenze elettriche

Turn OFF power supply before connecting the device;

connect according to explanation in the ”Electrical connections” section;

connect Zero setting/Preset input to 0Vdc, if not used; to zero set the encoder, connect Zero setting to +Vdc for 100 µs at least,

then disconnect +Vdc; normally voltage must be at 0Vdc; we suggest performing the zero set when the encoder is in stop;

in compliance with 2014/30/EU norm on electromagnetic compatibility, following precautions must be taken:

- before handling and installing the equipment, discharge electrical charge from your body and tools which may come in touch

with the device;

- power supply must be stabilized without noise; install EMC filters on device power supply if needed;

- always use shielded cables (twisted pair cables whenever possible);

- avoid cables runs longer than necessary;

- avoid running the signal cable near high voltage power cables;

- mount the device as far as possible from any capacitive or inductive noise source; shield the device from noise source if needed;

- to guarantee a correct working of the device, avoid using strong magnets on or near by the unit;

- minimize noise by connecting the shield and/or the connector housing and/or the frame to ground Make sure that ground is not

affected by noise The connection point to ground can be situated both on the device side and on user’s side The best solution to

minimize the interference must be carried out by the user

Effettuare le connessioni elettriche esclusivamente in assenza di tensione;

rispettare le connessioni riportate nella sezione “Electrical connections”;

collegare l'ingresso Zero setting a 0Vdc se non utilizzato; per azzerare la posizione collegare Zero setting a +Vdc per almeno 100

µs, poi scollegare +Vdc; normalmente deve avere tensione 0Vdc; effettuare l'azzeramento con encoder fermo;

in conformità alla normativa 2014/30/UE sulla compatibilità elettromagnetica rispettare le seguenti precauzioni:

- prima di maneggiare e installare il dispositivo, eliminare la presenza di carica elettrostatica dal proprio corpo e dagli utensili che

verranno in contatto con il dispositivo;

- alimentare il dispositivo con tensione stabilizzata e priva di disturbi, se necessario, installare appositi filtri EMC all’ingresso

dell’alimentazione;

- utilizzare sempre cavi schermati e possibilmente “twistati”;

- non usare cavi più lunghi del necessario;

- evitare di far passare il cavo dei segnali del dispositivo vicino a cavi di potenza;

- installare il dispositivo il più lontano possibile da eventuali fonti di interferenza o schermarlo in maniera efficace;

- per garantire un funzionamento corretto del dispositivo, evitare l'utilizzo di apparecchiature con forte carica magnetica in

prossimità dell'unità;

- collegare la calza del cavo e/o la custodia del connettore e/o il corpo del dispositivo a un buon punto di terra; assicurarsi che il

punto di terra sia privo di disturbi Il collegamento a terra può essere effettuato sul lato dispositivo e/o sul lato utilizzatore; è

compito dell’utilizzatore valutare la soluzione migliore da adottare per minimizzare i disturbi

Mechanical safety Avvertenze meccaniche

Install the device following strictly the information in the “Mounting instructions” section;

mechanical installation has to be carried out with stationary mechanical parts;

do not disassemble the device;

do not tool the device or its shaft;

delicate electronic equipment: handle with care; do not subject the device and the shaft to knocks or shocks;

respect the environmental characteristics of the product

Montare il dispositivo rispettando rigorosamente le istruzioni riportate nella sezione “Istruzioni di montaggio”;

effettuare il montaggio meccanico esclusivamente in assenza di parti meccaniche in movimento;

non disassemblare il dispositivo;

non eseguire lavorazioni meccaniche sul dispositivo;

dispositivo elettronico delicato: maneggiare con cura; evitare urti o forti sollecitazioni sia all’albero che al corpo del dispositivo;

utilizzare il dispositivo in accordo con le caratteristiche ambientali dello stesso

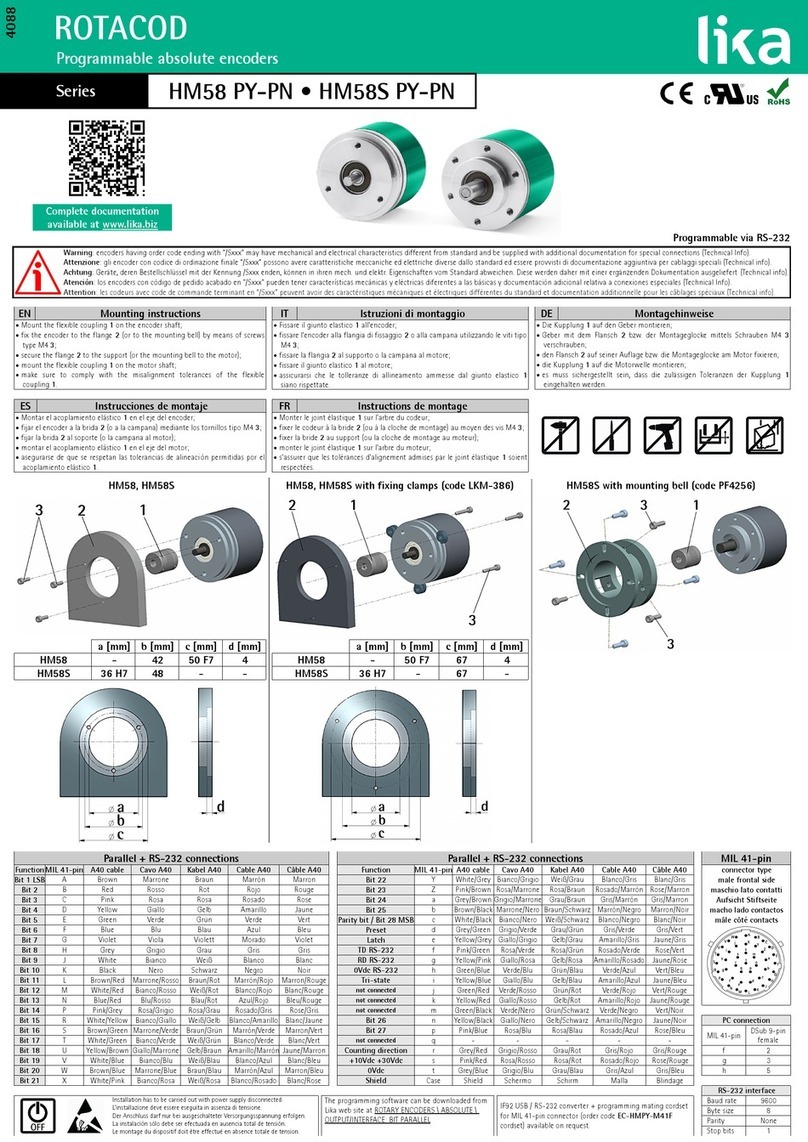

Order code (example)

C50MA - SC 1 - 17 - 6 - B M2

SSI Binary BG 1 m long cable

BiSS C-mode SC Lx x m long cable

Mx x m cable + M12 8 pin

+5Vdc ±5% power supply 1

Standard fixing plate

Resolution in bits (see datasheet for available options) A No fixing plate

B Type B fixing plate

Shaft diameter (mm) D Type D fixing plate

Refer to the technical catalogue for the available combinations