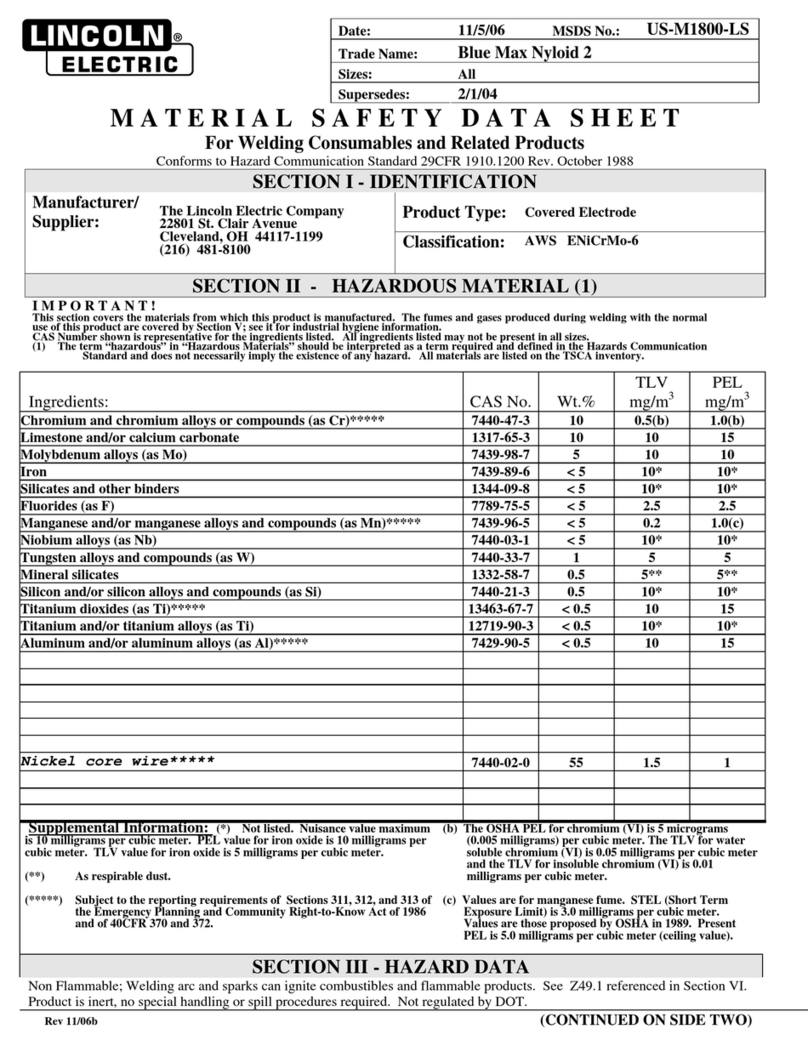

Product: Lincore 102HC

Date: 11/15/06

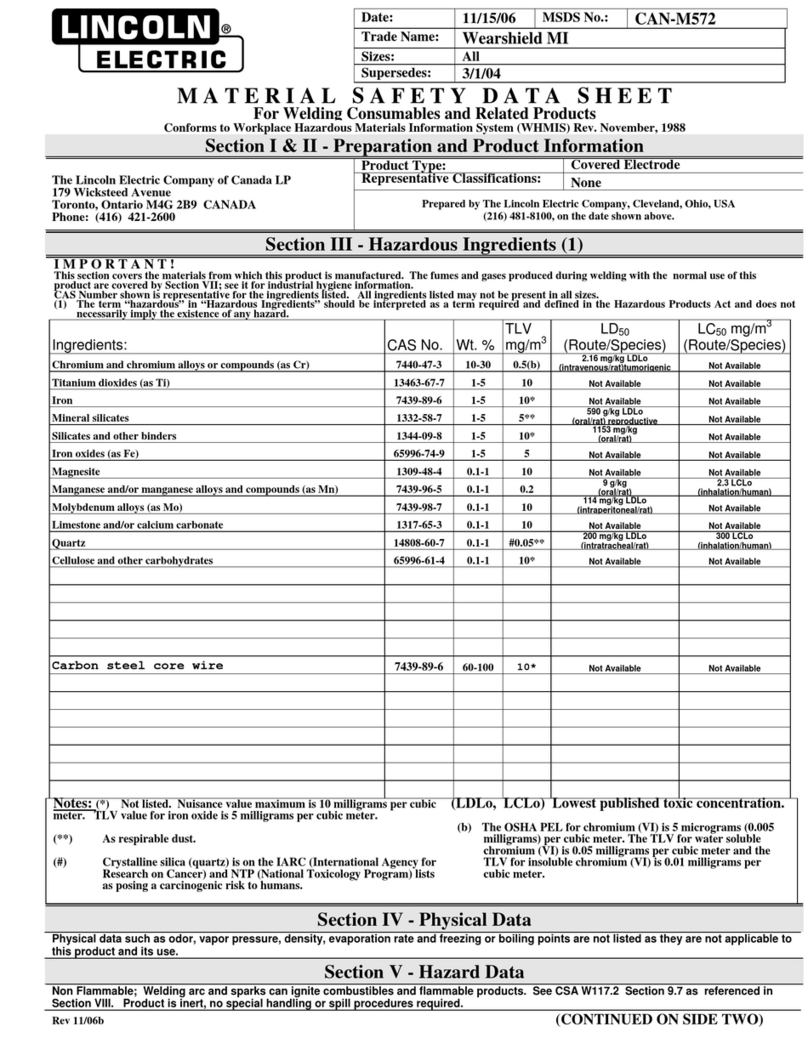

Section VI - Health Hazard Data and Toxicological Properties

Acute Lethality Values: LC50 means the concentration of a substance in air that when administered by means of inhalation over a specified length of time

in an animal assay, is expected to cause the death of 50% of a defined animal population.

LD50 means the single dose of a substance that, when administered by a defined route in an animal assay, is expected to cause the death of 50% of

a defined animal population.

Threshold Limit Value: The ACGIH recommended general limit for Welding Fume NOS - (Not Otherwise Specified) is 5 mg/m3.

The TLV-TWA is the time-weighted average concentration for a normal 8-hour workday and a 40 hour workweek, to which nearly all workers may be

repeatedly exposed, day after day, without adverse effect. See Section VII for specific fume constituents which may modify this TLV. Threshold Limit

Values are figures published by the American Conference of Government Industrial Hygienists.

Effects of Overexposure: Electric arc welding may create one or more of the following health hazards:

Fumes and Gases can be dangerous to your health. Common entry is by inhalation. Other possible routes are skin contact and ingestion.

Short-term (acute) overexposure to welding fumes may result in discomfort such as metal fume fever, dizziness, nausea, or dryness or irritation of

nose, throat, or eyes. May aggravate pre-existing respiratory problems (e.g. asthma, emphysema).

Long-term (chronic) overexposure to welding fumes can lead to siderosis (iron deposits in lung) and may affect pulmonary function. Manganese

overexposure can affect the central nervous system, resulting in impaired speech and movement. Bronchitis and some lung fibrosis have been

reported. Chromates may cause ulceration and perforation of the nasal septum. Liver damage and allergic reactions, including skin rash, have

been reported. Chromates contain the hexavalent form of chromium. Hexavalent chromium and its compounds are on the IARC (International

Agency for Research on Cancer) and NTP (National Toxicology Program) lists as posing a cancer risk to humans.

Arc Rays can injure eyes and burn skin. Skin cancer has been reported.

Electric Shock can kill. If welding must be performed in damp locations or with wet clothing, on metal structures or when in cramped positions such as

sitting, kneeling or lying, or if there is a high risk of unavoidable or accidental contact with workpiece, use the following equipment: Semiautomatic DC

Welder, DC Manual (Stick) Welder, or AC Welder with Reduced Voltage Control.

Section VII - Reactivity Data

Hazardous Decomposition Products: Welding fumes and gases cannot be classified simply. The composition and quantity of both are dependent upon the

metal being welded, the process, procedure and electrodes used.

Other conditions which also influence the composition and quantity of the fumes and gases to which workers may be exposed include: coatings on the metal

being welded (such as paint, plating, or galvanizing), the number of welders and the volume of the worker area, the quality and amount of ventilation, the

position of the welder's head with respect to the fume plume, as well as the presence of contaminants in the atmosphere (such as chlorinated hydrocarbon

vapors from cleaning and degreasing activities.)

When the electrode is consumed, the fume and gas decomposition products generated are different in percent and form from the ingredients listed in

Section III. Decomposition products of normal operation include those originating from the volatilization, reaction, or oxidation of the materials shown in

Section III, plus those from the base metal and coating, etc., as noted above.

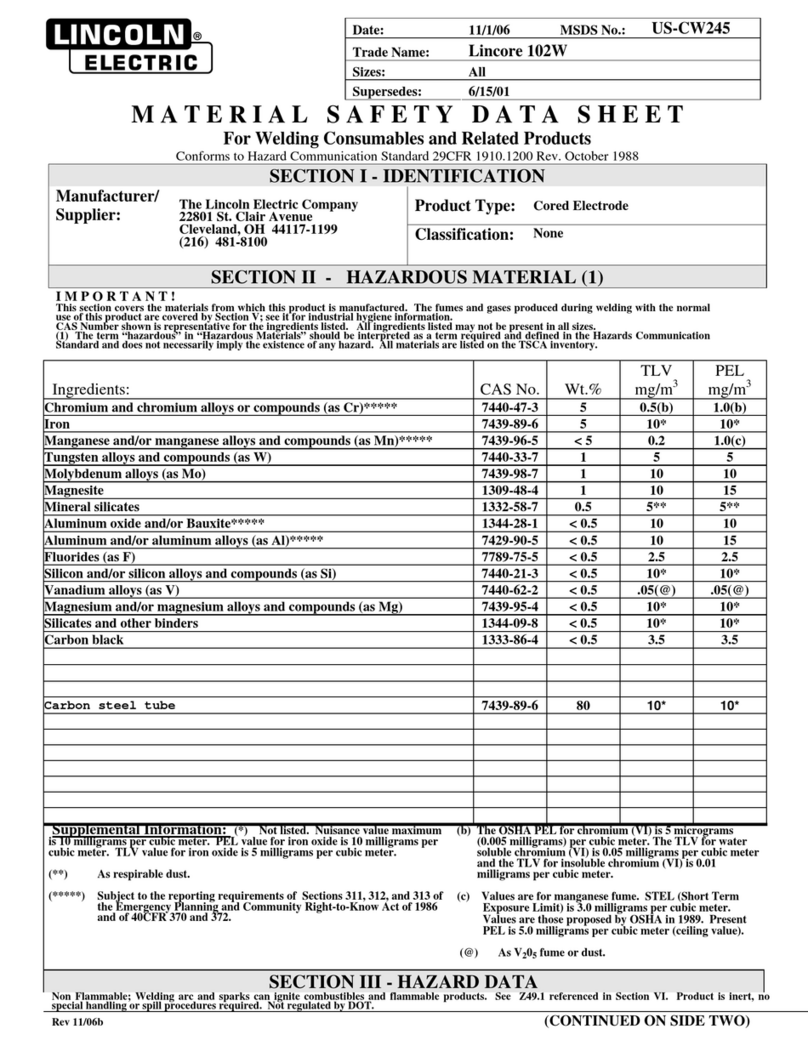

Reasonably expected fume constituents of this product would include: Primarily iron oxides and fluorides; secondarily complex oxides of

aluminum, calcium, chromium, magnesium, manganese, potassium, silicon, sodium and tungsten when used with recommended Lincolnweld

fluxes. (See MSDS for flux being used.)

Maximum fume exposure guideline for this product (based on manganese content) is 3.0 milligrams per cubic meter.

Gaseous reaction products may include carbon monoxide and carbon dioxide. Ozone and nitrogen oxides may be formed by the radiation from the arc.

Determine the composition and quantity of fumes and gases to which workers are exposed by taking an air sample from inside the welder's helmet if worn or

in the worker's breathing zone. Improve ventilation if exposures are not below limits. See ANSI/AWS F1.1, F1.2, F1.3 and F1.5, available from the

American Welding Society, 550 N.W. LeJeune Road, Miami, FL 33126.

Section VIII - Preventive Measures and Precautions for Safe Handling and Use

Read and understand the manufacturer's instruction and the precautionary label on the product. Request Lincoln Safety Publication E205. See Canadian

Standards Association Standard CSA-W117.2 “Safety in Welding, Cutting, and Allied Processes” published by the Canadian Standards Association, 178

Rexdale Blvd., Rexdale, Ontario M9W1R3 for more details on many of the following:

Ventilation: Use enough ventilation, local exhaust at the arc, or both to keep the fumes and gases from the worker's breathing zone and the general area.

Train the welder to keep his head out of the fumes. Keep exposure as low as possible.

Respiratory Protection: Use respirable fume respirator or air supplied respirator when welding in confined space or general work area when local exhaust

or ventilation does not keep exposure below TLV.

E

ye Protection: Wear helmet or use face shield with filter lens shade number 12 or darker. Shield others by providing screens and flash goggles.

Protective Clothing: Wear hand, head, and body protection which help to prevent injury from radiation, sparks and electrical shock. See W117.2.

At a minimum this includes welder's gloves and a protective face shield, and may include arm protectors, aprons, hats, shoulder protection, as well as dark

substantial clothing. Train the welder not to permit electrically live parts or electrodes to contact skin . . . or clothing or gloves if they are wet. Insulate from

work and ground.

Disposal Information: Discard any product, residue, disposable container, or liner as ordinary waste in an environmentally acceptable manner according

to Federal, State and Local regulations unless otherwise noted. No applicable ecological information available.

Section IX - Emergency and First Aid Procedures

Call for medical aid. Employ first aid techniques recommended by the Canadian Red Cross. IF BREATHING IS DIFFICULT give oxygen. IF NOT

BREATHING employ CPR (Cardiopulmonary Resuscitation) techniques. IN CASE OF ELECTRICAL SHOCK, turn off power and follow recommended

treatment. In all cases call a physician.