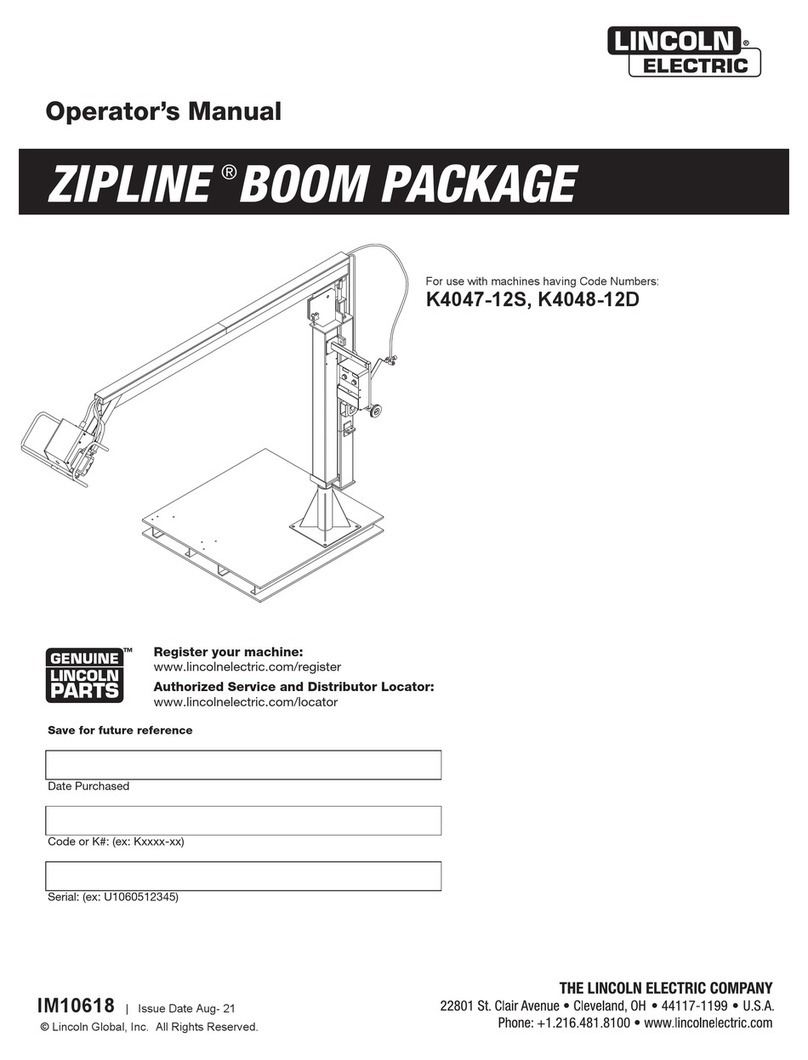

Lincoln Electric K3589-1 User manual

Other Lincoln Electric Welding Accessories manuals

Lincoln Electric

Lincoln Electric LT-7 Tractor User manual

Lincoln Electric

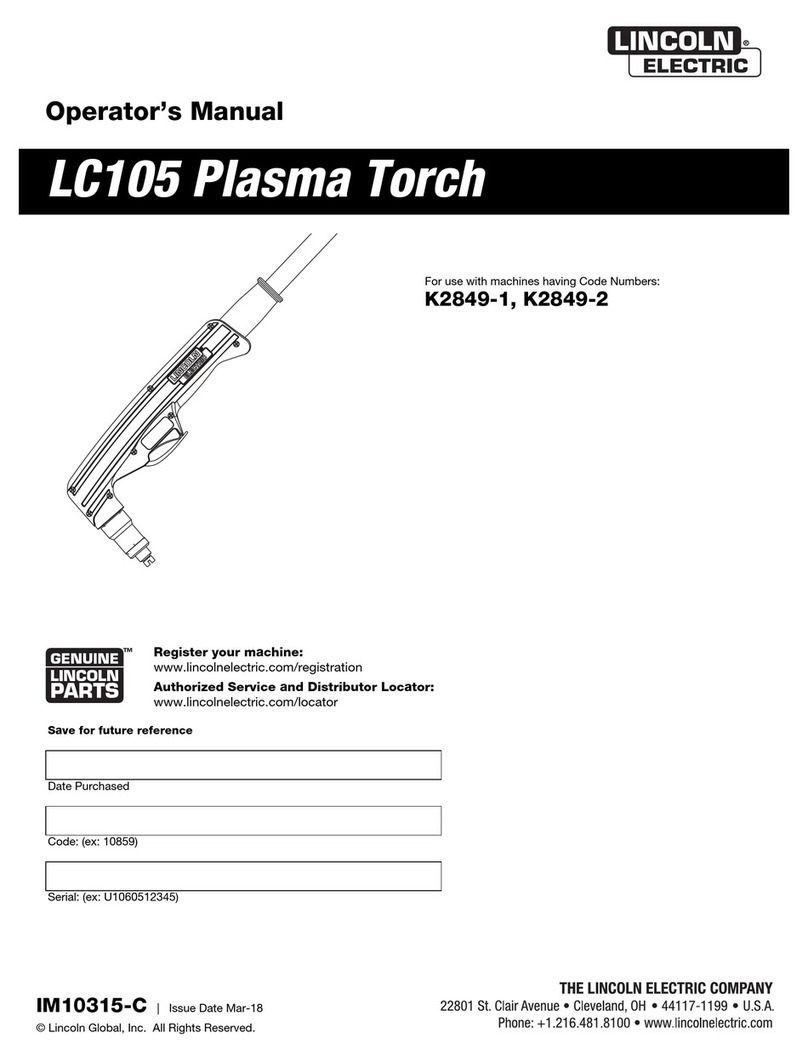

Lincoln Electric LC105 User manual

Lincoln Electric

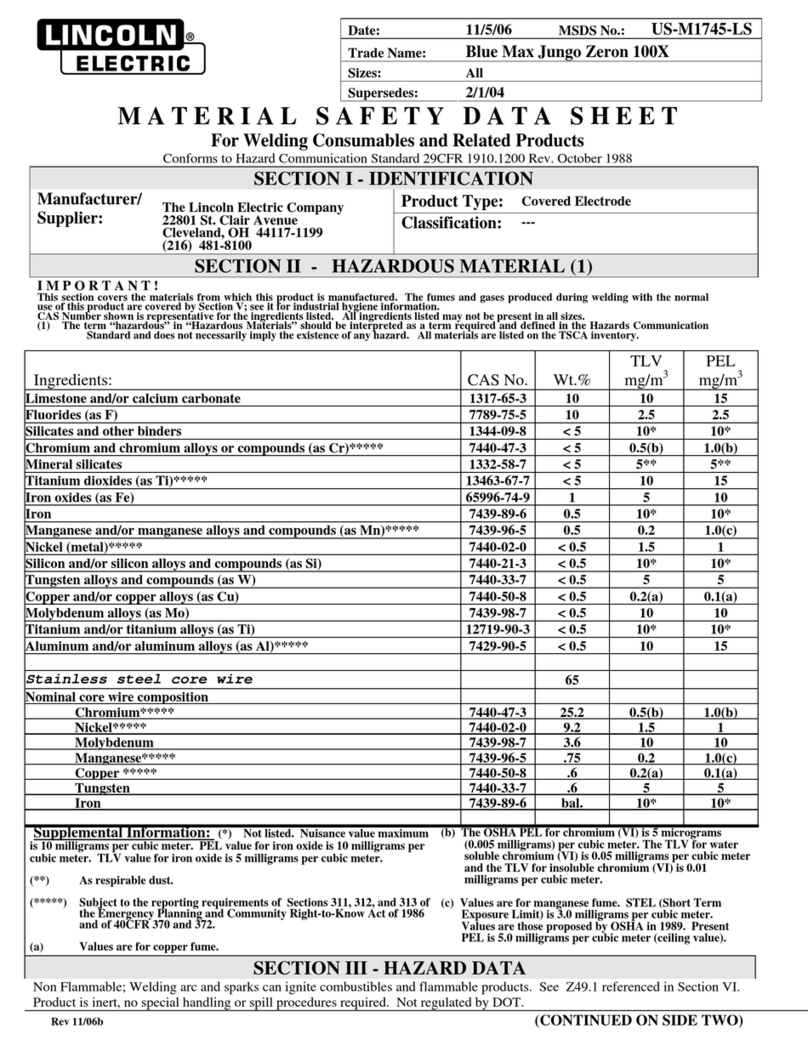

Lincoln Electric US-M1745-LS User manual

Lincoln Electric

Lincoln Electric MINIFLEX K2376-1 User manual

Lincoln Electric

Lincoln Electric VIKING 2450 Series User manual

Lincoln Electric

Lincoln Electric IM839 User manual

Lincoln Electric

Lincoln Electric INNERSHIELD Series User manual

Lincoln Electric

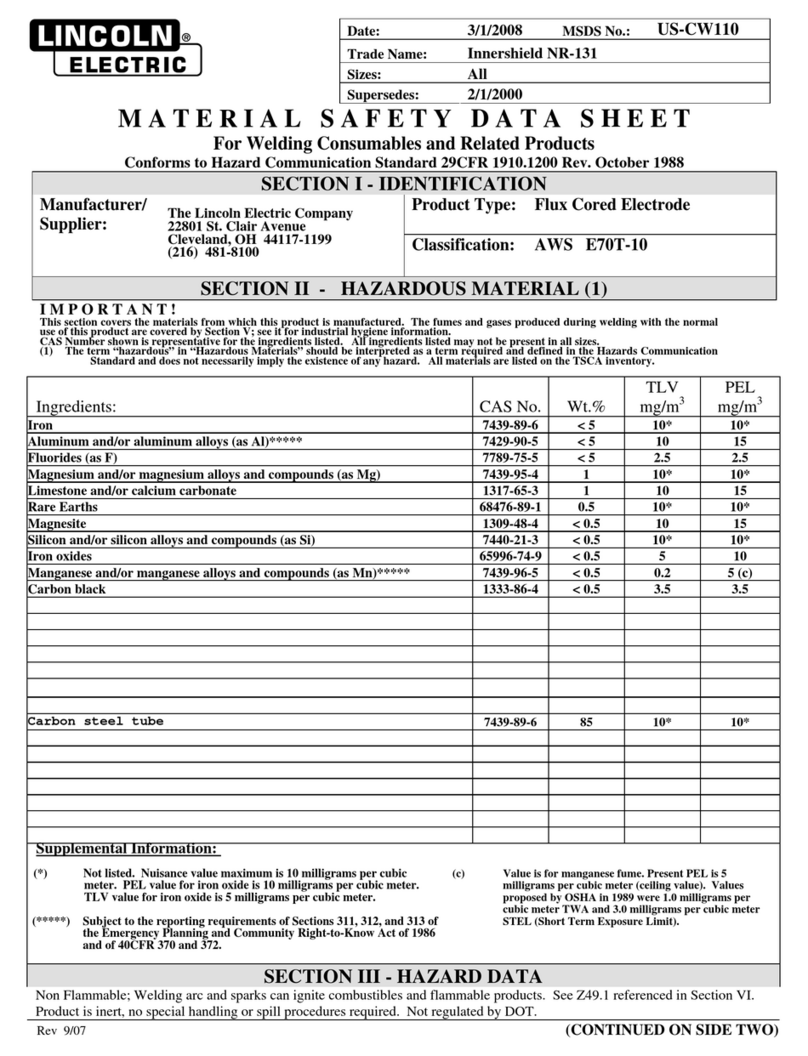

Lincoln Electric Innershield NR-131 User manual

Lincoln Electric

Lincoln Electric Harris Port-A-Torch 19601 User manual

Lincoln Electric

Lincoln Electric Statiflex 800 User manual

Lincoln Electric

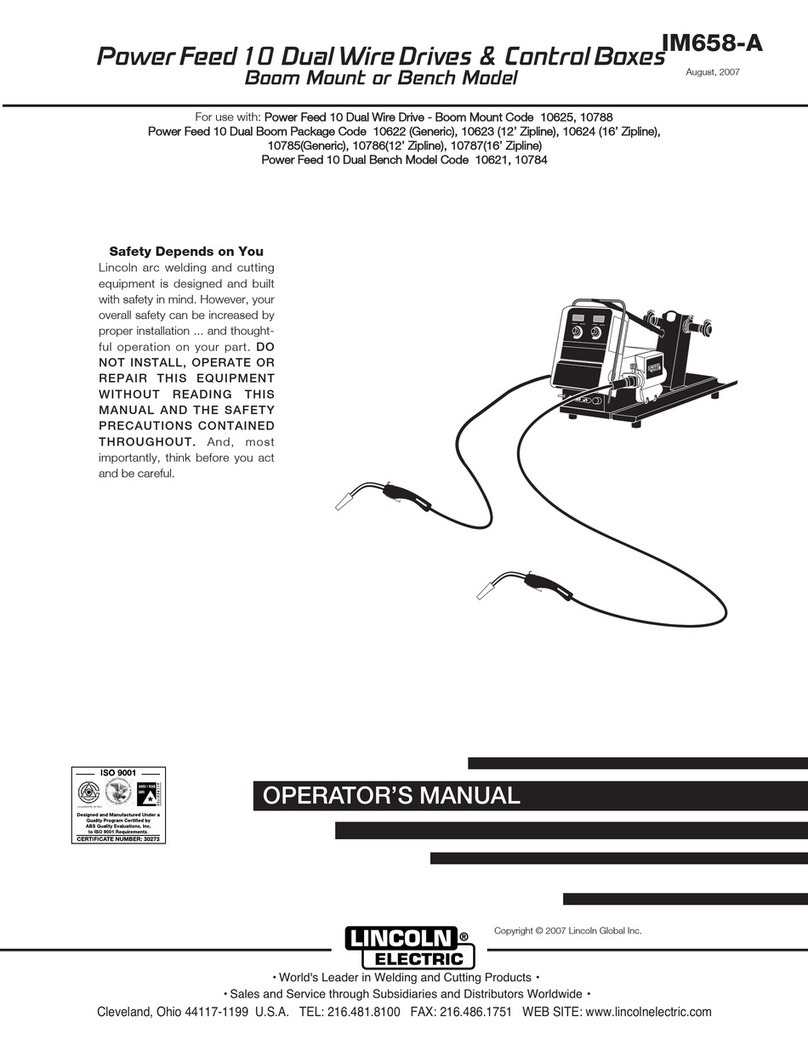

Lincoln Electric IM658-A User manual

Lincoln Electric

Lincoln Electric VIKING 4C 3350 Series User manual

Lincoln Electric

Lincoln Electric POWER WAVE STT User manual

Lincoln Electric

Lincoln Electric Lincolnweld 780 User manual

Lincoln Electric

Lincoln Electric LN-7 User manual

Lincoln Electric

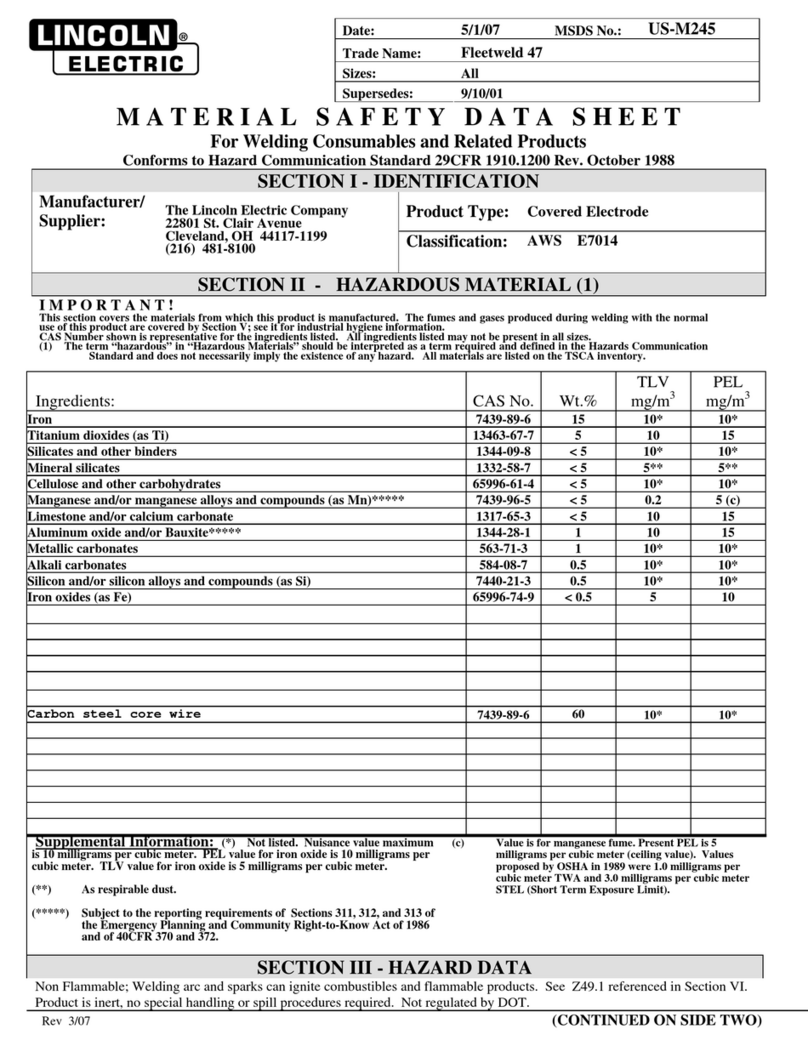

Lincoln Electric Fleetweld 47 User manual

Lincoln Electric

Lincoln Electric PIPELINER LN-23P User manual

Lincoln Electric

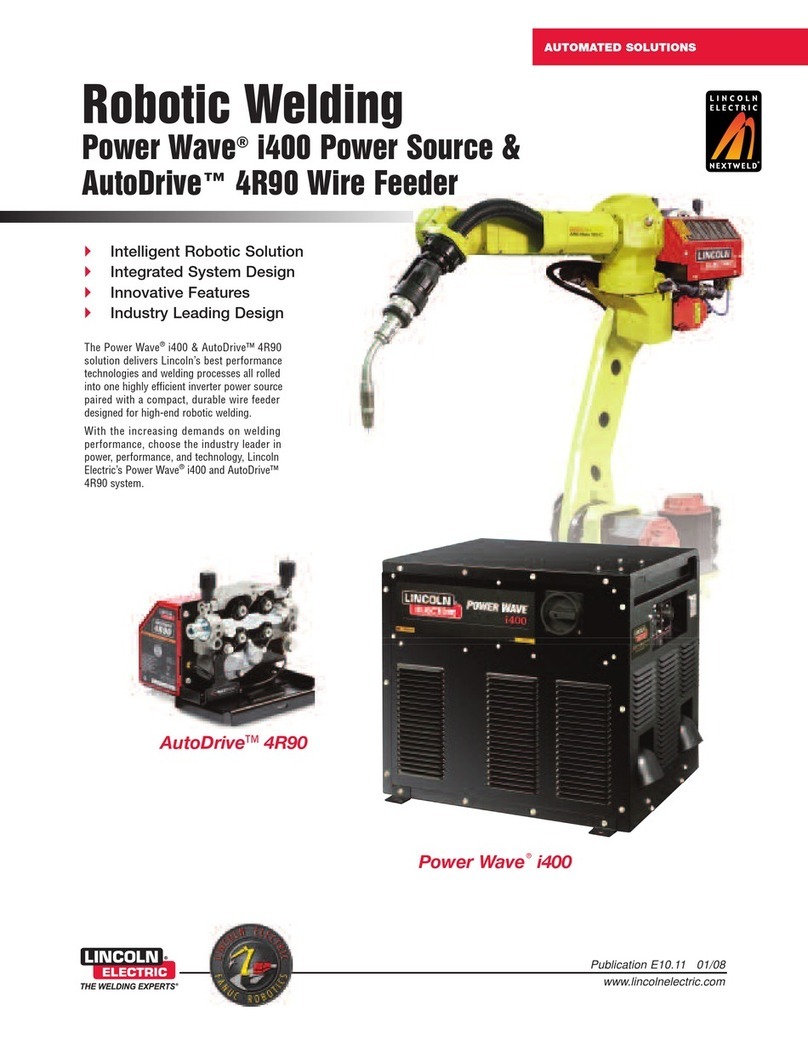

Lincoln Electric AutoDrive 4R90 User manual

Lincoln Electric

Lincoln Electric X-Tractor 3A User manual

Lincoln Electric

Lincoln Electric LN-25 User manual