LINCOLN GmbH • Postfach 1263 • D-69183 Walldorf • Tel +49 (6227) 33-0 • Fax +49 (6227) 33-259 • Tx 466088

User’s Manual

Operating Instructions

Page 3 of 12

1.3A-18001-A96

Subject to change without notice

The User’s Manual as well as the Safety Instructions must be

read by the operating and maintenance personnel before any

intervention is undertaken at the change-over valve. They must

be available on the site where the change-over valve is in opera-

tion.

The change-over valve model DU-1 is exclusively designed for

use in two-line centralized lubrication systems.

The maximum ratings mentioned in the Technical Data, particu-

larly the operating pressure of 350 bar, must on no account be

exceeded.

Any other use is not in accordance with the specified instruc-

tions.

Safety Instructions

The manufacturer is not liable for damages resulting from an

improper use.

Alteration or modifications of the change-over valve are only al-

lowed if approved by the manufacturer.

For repairs use only original spare parts. If other spare parts

are used, the manufacturer may be released from its liability for

the resulting consequences.

The change-over valve should only be used if it is in good tech-

nical condition. Defects and faults which may impair its operati-

on and safety must be remedied immediately.

If you need more information than is given in this User’s Manu-

al, please contact our company (see address below).

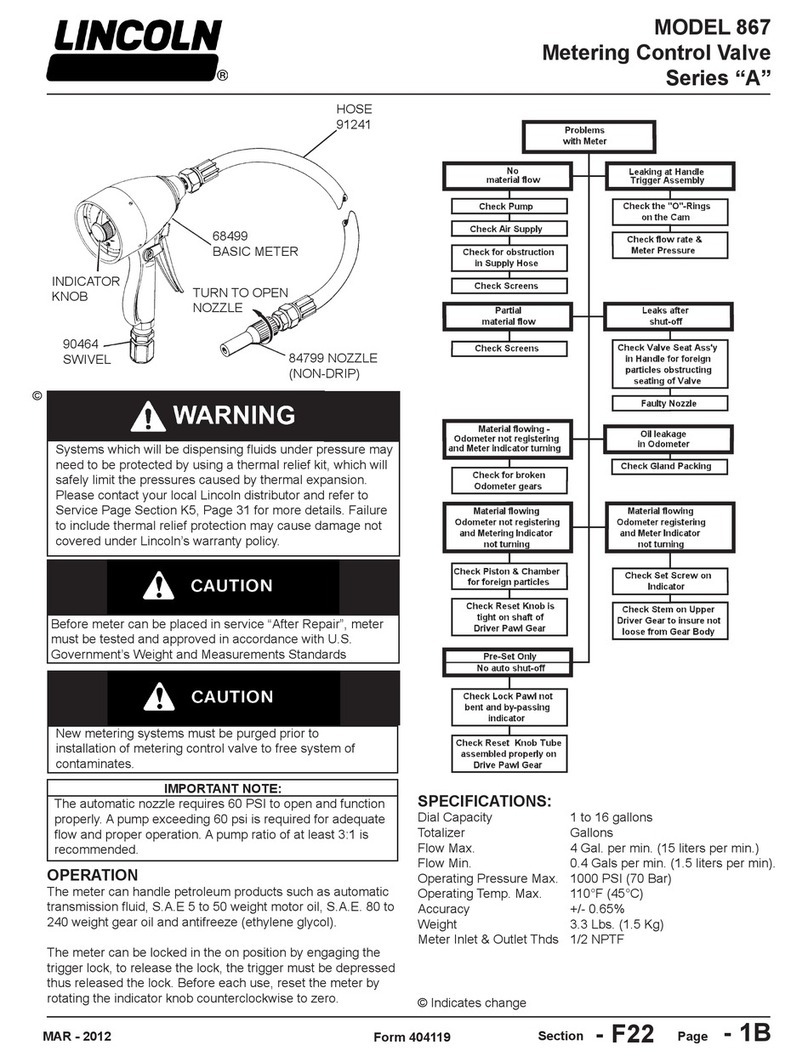

Technical Data

Flow rate: ......................................................... max. 14 dm³/h

Change-over pressure: ................................... min. 140 bar

......................................................................... max. 350 bar

Factory setting:................................................ 170 bar

Operating pressure: ........................................ max. 350 bar

Threaded connection: ..................................... G 1/2 i.

Dispensed media: ........................................... Lubricating oils

......................................................................... from 60 cSt on-

......................................................................... wards at +40°C

......................................................................... Greases up to

......................................................................... NLGI-grade 3

(depending on

operating tempe-

rature)

Operating temperature:.............................. - 20 ° C to + 80°C

Mounting position: ...................................... variable

Position switch:

Nominal circuit voltage:.............................. 500 V, 25-60 Hz

Continuous current:.................................... 10 A

Operating current: ...................................... 4 A

Type of protection:...................................... IP 67

further technical details:............................. refer to Data sheet

.................................................................... 93G-10001-A95

Application

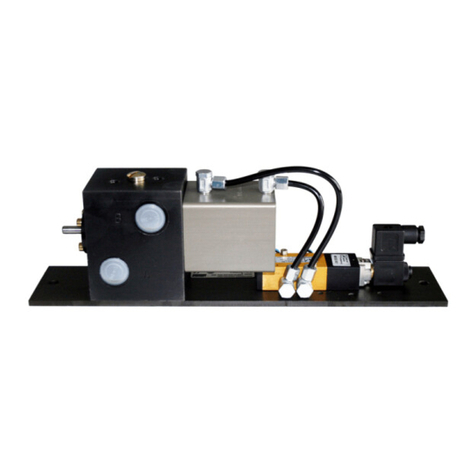

The model DU-1 pressure-controlled change-over valve is desi-

gned for use in two-line lubrication systems operating within the

above specified pressure range and flow rate. These systems

include the central lubrication pumps model ZPU 08/14, ZPU

01/02, HJ 2 and ZPU 75.

For values exceeding the mentioned ranges, one can use the

electric motor-operated change-over valve model EM-U2 in con-

junction with end-of-line pressure switches.

The model DU1 change-over is available in three versions:

Model Part. No.

DU1-G mounted on base plate 617-28683-1

DU1-GK with indicator pin, mounted on

base plate 617-28619-1

DU1-GKS with indicator pin and limit switch,

mounted on base plate 617-28620-1

Structure and Operation

The principle of operation of the change-over valve is similar to

that of a 4/2-way valve which alternately discharges the lubri-

cant fed by the pump into one of the two main lines while the

other main line is connected to the return line connection of the

pump.

The figures 1 and 2 show a schematic illustration of the operati-

on of the DU-1 change-over valve. The lines marked in black

represent the pressure lines and the white lines the pressure

relief lines.

line under pressure

line relieved

control lubricant