Description

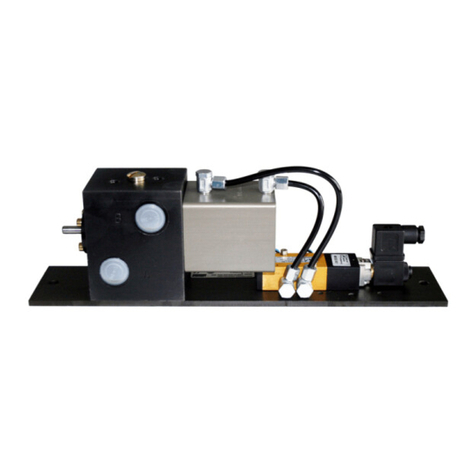

Lubrication controller 85307 is a universal

electronic control unit compatible with

dual-line, single-line and progressive

lubrication systems. Provides flexibility and

control over traditional single-line systems.

Controller digital display quickly identifies

system status with easy-to-identify codes.

Programming of unit requires simple

information allowing operator to focus

on specific utilized system.

Features

• Runs progressive, single-line and

dual-line lubrication systems.

• Timing intervals from 5 seconds to

24 hours.

• Cycle counting.

• 10 V to 30 V operation.

• Short circuit/open circuit detection with

audible warning.

• External fault lamp drive (flash or steady

output).

• Low level reservoir monitoring.

• Two sensor switch inputs.

• Visual and audible fault indication.

• Non-volatile memory.

• Built-in blown fuse indicator.

• 3-digit LED display indicates exact

system status.

• Simple setup procedure.

• Test mode allows testing of all circuits

connected to controller.

• Practical housing with mounting bracket.

Table 1

Specifications

Voltage 10 V

to 30 V

Current drain 150 mA maximum (no load), 70 mA nominal

Pump output 7 A rms. maximum

Lamp output 3 A maximum

Switching Solid state short circuit protected

Fuse 8 A fast blow 0.79 in (20 mm) glass

Connection 14 way MOLEX MINIFIT - JR

Communications RS232 type

Dimensions 2.8 × 5.7 × 1.5 in (70 × 145 × 38 mm) 1)

Weight 0.66 lbs (300 g)

Protection IP54

Temperature range 5 °F to 122 °F (–15 °C to +50 °C)

1) Includes mounting bracket.

Contents

Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Operational precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Explanation of signal words for safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Keypad layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

LED code descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Setup mode

Progressive-line system with no monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Running system (pump run). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Running system (pump pause). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Wiring diagram of progressive-line system without sensors . . . . . . . . . . . . . . . . . . . . . 15

Wiring of pump with solenoid relay switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Setup mode

Progressive-line system with reservoir monitoring, run and pause time only. . . . . . 16

Run mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Running system (pump run). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Running system (pump pause). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Setup mode

Progressive-line system with reservoir monitoring using run cycle counter . . . . . . . 22

Run mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Running system (pump run). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Running system (pump pause). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Wiring of pump with progressive-line system with sensors . . . . . . . . . . . . . . . . . . . . . . 28

Fault indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2 3