3 / 19NTI AG / LinMot

1. System overview ............................................................................................ 4

1.1 References .................................................................................................................. 4

1.2 Connecting In and Out ............................................................................................... 4

2. Setup in the PLC ............................................................................................ 5

2.1 Copy Device Description File ................................................................................... 5

2.2 Scan the EtherCAT slave devices ............................................................................ 6

3. Process Data Object (PDO) Configuration .................................................... 11

3.1 Input PDO Modules ................................................................................................... 11

3.1.1 Default Inputs: AT 1 ........................................................................................... 11

3.1.2 Input: Following distance S-0-0189 ................................................................. 11

3.1.3 Input: DC bus voltage S-0-0380 ....................................................................... 11

3.1.4 Input: State Var P-1-2914 .................................................................................. 11

3.1.5 Input: X4 Inputs P-1-3205 .................................................................................. 11

3.2 Output PDO Modules ................................................................................................ 12

3.2.1 Default Outputs: MDT 1 ..................................................................................... 12

3.2.2 Output: Velocty command value S-0-0036 ..................................................... 12

3.3 Typical Startup Telegrams ...................................................................................... 12

3.4 Adding Parameters or Variables to the PDO data by UPID ................................. 12

4. Asynchronous Configuration Protocol SoE .................................................. 15

4.1 Communication SoE Profile Area ........................................................................... 15

4.2 Generic LinMot SoE Parameter Mapping ............................................................... 15

5. EtherCAT SoE Parameters ............................................................................ 16

5.1 Parameters ................................................................................................................ 16

5.1.1 EtherCAT/Dis-/Enable ....................................................................................... 16

5.1.2 EtherCAT/Station Alias/Alias Address Source ............................................... 16

5.1.3 EtherCAT/Station Alias/Alias Address Parameter ......................................... 16

5.1.4 EtherCAT/Station Alias/Alias Address Parameter Mask ............................... 17

5.1.5 EtherCAT/NC Configuration/Velocity Scale Numerator /Denominator ....... 17

5.1.6 EtherCAT/Connection Timeout/Timeout Behavior ........................................ 17

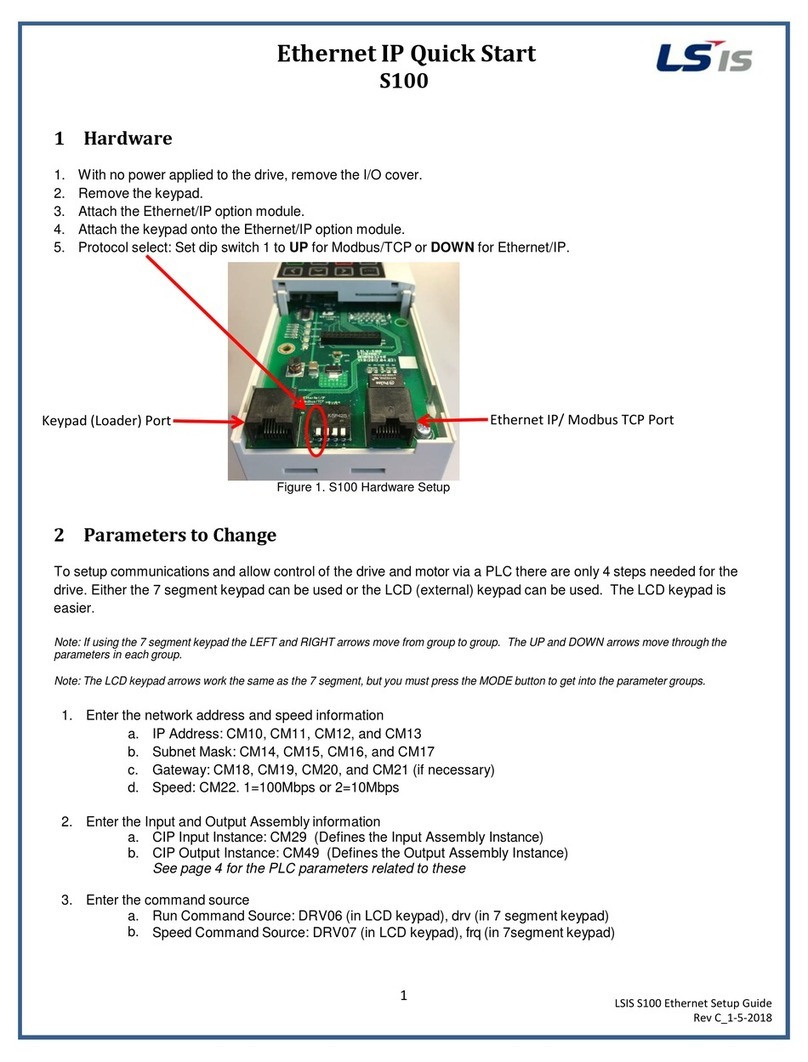

6. Connecting to the EtherCAT Network ........................................................... 18

6.1 Pin Assignment of the Connectors X17-X18 ......................................................... 18