LINSHANG LS253 User manual

Shenzhen Linshang Technology Co., Ltd.

3/12/2022 Page 1 of 13

LS253

Leeb Hardness Tester

User Manual V1.0

Please read this manual carefully before using and reserve it for reference.

Shenzhen Linshang Technology Co., Ltd.

3/12/2022 Page 2 of 13

I. Product Introduction

The Leeb hardness tester detects hardness based on the Leeb hardness measurement principle and

can measure the hardness of a variety of metal materials. The tester adopts advanced digital probe

technology, digital signal processing is done directly on the probe, which is not easily disturbed and

provides excellent testing accuracy. The probe has a built-in direction sensor, which automatically

compensates for the measurement error in different impact directions. The instrument has a variety of

built-in hardness systems, which can be converted between Leeb (HL), Vickers (HV), Brinell (HB), Shore

(HS), Rockwell (HRA), Rockwell (HRB), Rockwell (HRC) and tensile strength (σb). The instrument can

connect with impact devices D, DL, DC and C.

Impact device D is suitable for assessing the hardness of common metal materials;

Impact device DL is suitable for hardness measurement of slender and narrow grooves, tooth

surfaces and the bottom of inner holes;

Impact device DC is suitable for testing the hardness of inner holes and narrow parts with short size;

Impact device C is ideal for measuring the hardness of surface hardening layers and parts with

small masses or thin thickness with small impact force.

Standards for the product:

GB/T 13794.1 Metallic materials-Leeb hardness test-Part 1: Test method

GB/T 13794.2 Metallic materials-Leeb hardness test-Part 2: Verification and calibration of

hardness tester

GB/T 13794.2 Metallic materials-Leeb hardness test-Part 3: Calibration of reference blocks

GB/T 13794.4 Metallic materials-Leeb hardness test-Part 4: Tables of hardness values conversion

JB/T 9378-2001 Industry standard of Leeb hardness tester

JJG 747-1999 Verification regulation of Leeb hardness tester

II. Parameters

Probe

Impact device D/ Impact device DC / Impact device DL/

Impact device C

Hardness Scales

HL, HV, HB, HS, HRA, HRB, HRC

Measurement Range

Impact device D/DC:

HLD: (170-960); HV(83-976); HB(30-651); HRC(17.6-68.5);

HS(26.4-99.5); HRB(13.5-100); HRA(60-85.8)

Impact device DL:

Shenzhen Linshang Technology Co., Ltd.

3/12/2022 Page 3 of 13

HLDL(170-960); HV(194-976); HB(140-651); HRC(19.8-

68.5); HS(26.4-99.5); HRB(59.6-99.6); HRA(60-85.5)

Impact device DL:

HLC(170-960); HV(80-996); HB(80-683); HRC(20-69.5);

HS(31.9-102.3)

Resolution

1HL

Accuracy

±12 HL, ±6 HL (typical)

Repeatability

6HL

Display

240 * 16 dot matrix LCD

Power Supply

2 AA alkaline dry batteries

Host Size

142*72*28 mm

Probe Size

148*31*25 mm

Weight

247g

Working Temperature Range

-10~50℃,0~85%RH(no condensation)

Storage Temperature Range

-10~60℃,0~85%RH(no condensation)

III. Features

1. Probe plug-in design, support different Leeb hardness tester impact devices.

2. The tester uses advanced digital probe technology, digital signal processing directly on the probe to

complete, which is not easy to interfere with and provides excellent test accuracy.

3. Built-in direction sensor, automatically compensates for the measurement error of different impact

directions.

4. Providing a variety of hardness scales to switch, no more tedious manual check table

5. QC inspection, the tester can set upper and lower limits to determine whether the incoming material

is qualified and achieve rapid detection of incoming material.

6. Statistics function, the tester can automatically count the maximum value, minimum value, and

average value of the last 9 measured values.

7. Users can calibrate the standard parts to eliminate the error.

Shenzhen Linshang Technology Co., Ltd.

3/12/2022 Page 4 of 13

8. It can print the measurement data after connecting Bluetooth printer.

9. Built-in Bluetooth function, it can connect to the mobile APP and realize measurement data sharing.

10. Low power consumption, powered by 2AA alkaline batteries and it can work continuously for more

than 100 hours.

IV. Operation

1. Power on/off

Power on:

Short press button, the version and the serial number of the instrument host and probe are

displayed on the screen at the same time after powering on, and then the instrument will enter the

measurement interface and the measured values before powering off are displayed.

Power off:

Long press the button to shut down the tester or click the “Shutdown” option in the menu, the

instrument will automatically shut down when the time without any operation is longer than the auto-

shutdown time.

2. Measurement

Impact device D/DL/C:

Loading:

Push down the loading sleeve of the probe to lock the impact body.

Positioning:

Press the probe firmly against the surface of the object to be measured and keep it still.

Measurement:

Press the release button on the top of the probe to measure the hardness of the object.

Impact device DC:

Loading:

Push the impact body from the bottom to the locking position with the push rod.

Positioning:

Press the probe firmly against the surface of the object to be measured and keep it still.

Shenzhen Linshang Technology Co., Ltd.

3/12/2022 Page 5 of 13

Measurement:

Press the release button on the top of the probe to measure the hardness of the object.

There are two measurement modes:

(1) Statistics mode

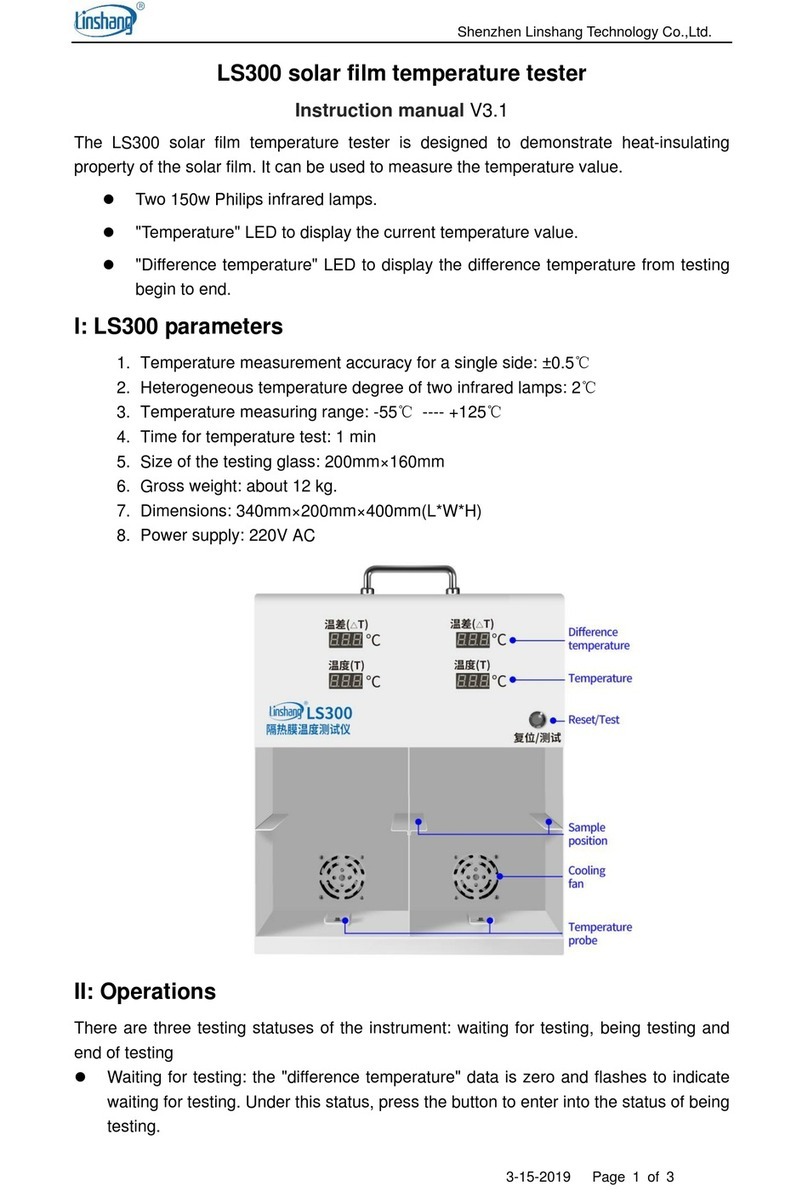

The interface of statistics mode is shown below (left). The instrument displays the maximum value,

minimum value, and average value of current statistics as well as the number of valid data. The

number of statistics is the last 9 valid measurement data, and when there are less than 9 data, the

actual amount of data prevails.

(2) QC mode

The QC mode interface is shown in the figure below (right), and the instrument judges whether the

measured value is qualified according to the set upper and lower limits.

Statistics mode QC mode

3. Setup and Calibration

Press and hold the button for 3 seconds in the off state or press the button briefly in the

measurement state to enter the Main Menu of the instrument with seven sub-options, press the and

briefly to select [System Setup, Hardness/Strength, Material, Hardness, Calibration, Exit, Shutdown],

short press the button to confirm the selection.

Shenzhen Linshang Technology Co., Ltd.

3/12/2022 Page 6 of 13

(1) System Setup

Language: Short press button or button to enter the language option and press the or

button to select the right language, then press button to confirm your selection.

Auto power off: short press the button or button to enter the shutdown time selection,

short press the or button to select the shutdown time, short press the button to

confirm.

Mode selection: short press the button or button to enter the mode selection interface,

press button to select the measurement mode, then short press the button to confirm.

Limit setting: Limit setting is only displayed in QC mode, short press the or button to enter

the limit setting interface, press or button to select [upper/lower limit/return] option, short

press the to confirm your option, short press to modify the value, finally, short

press the button to confirm the whole setting.

Restore factory settings: Press the button briefly to enter the restore factory selection interface.

button can toggle the [Yes/No] option, press the button briefly to confirm

the option and return to the setting interface.

(2) Hardness/Strength

Short press button to enter hardness/strength selection interface, and short press the or

Shenzhen Linshang Technology Co., Ltd.

3/12/2022 Page 7 of 13

button to select [hardness/strength], then short press the button to confirm the selection.

(3) Material

Short press the button to enter the material selection interface, short press the

button to select the corresponding material, then press the button to confirm the option and return

to the setting interface.

(4) Hardness Unit

The hardness unit is only displayed in hardness measurement mode, press the button briefly to

enter the hardness unit selection interface, press the or to select the hardness unit, press the

button briefly to confirm.

(5) Calibration

Short press the button to enter the calibration interface, the screen prompts [Please measure the

standard hardness block] and flashes, then you can measure the standard hardness block (single or

multiple times).After measurement, the cursor moves to the actual value area, then press or

button to adjust the actual value to the standard value of the hardness block. Short press the button

to end the adjustment, and press the or to select [Cancel]/[Back]/[Save] options.

Select [Cancel] and press button briefly to return to the calibration screen and wait for the

measurement again.

Select [Back], short press button to not save the calibration data and exit the calibration

screen.

Select [Save], press button briefly to save the current calibration data, and exit the calibration

interface.

(6) Exit

Short press button briefly to exit the main interface and enter the measurement interface.

(7) Power off

Shenzhen Linshang Technology Co., Ltd.

3/12/2022 Page 8 of 13

Short press button to power off the instrument.

4. History Records

In the measurement mode, press or briefly to view the historical data in the browse interface. The

instrument stores 9 sets of data totally, and the oldest recorded value is automatically deleted when there

are more than 9 sets of data. Record 1 is the earliest test data, and so on backward. Recorded data is

not lost when the instrument is turned off.

When pressing button to view the data, the data record number is increasing from the first one to the

last one; when pressing button to view the data, the data record number decreases from the

maximum to the minimum.

In the history view mode or measurement mode, press button briefly and the screen will show a

data deletion prompt, press button briefly to select [Yes] to delete all recorded data.

5. Aviation plug connection

When plugging out the probe, make sure not to violently rotate and pull the connector, but plug out the

plug by the way as shown in the following diagram.

V. Bluetooth printing function

The instrument has built-in Bluetooth communication module, which can be connected to Bluetooth

printer to print measurement data. Turn the DIP switch on the side of the Bluetooth printer to [ON], and

long press the power button to turn it on. Short press , the printer icon will be displayed on the

screen, and the [BLUETOOTH] blue indicator on the printer will be on continuously indicating successful

Shenzhen Linshang Technology Co., Ltd.

3/12/2022 Page 9 of 13

connection and the printer will print the current measurement results. If the device is connected to the

mobile APP, it will prompt whether to disconnect theAPP connection. Select [Yes] to disconnect theAPP

and connect the printer.

Note: The instrument can only be connected with the Bluetooth printer provided by the manufacturer,

other brands of printers are not guaranteed to be connected successfully.

VI. APP function

1. APP installation

APP supportsAndroid operating system 7.0 and above, choose one of the following methods to install:

(1) Use a mobile browser or WeChat to scan the QR code on the cover, follow the prompts to download

and install the APP.

(2) Search for "UT and HL" from the Google Play application market, download and install theAPP as

prompted.

APP icon

Precautions:

During installation or after installation for the first time open theAPP, mobile phone will prompt

permissions Settings, the customer should be all set to allow, can appear otherwise APP can't search to

the device, will not be able to use the APP.

2. Device Connection

Start the instrument, open the APP software, the LOGO interface will be displayed first. After the LOGO

is displayed for 3 seconds, the Bluetooth interface is entered if there is no bound Bluetooth device. Click

"Start searching", the prompt " searching for device..." , and list the available Bluetooth devices found;

Click the "Stop searching" button to stop searching for Bluetooth devices. Click the device that matches

the SN of the instrument and wait for the device to connect.After the connection is successful, it will

jump to the "Measure" interface. If the instrument is connected to the Bluetooth printer, it will prompt

whether to disconnect the printer, select [Yes] to disconnect the printer and connect the APP.

Shenzhen Linshang Technology Co., Ltd.

3/12/2022 Page 10 of 13

Bluetooth interface

If the APP already has a bound Bluetooth device, the logo interface will stay for 3 seconds and

automatically search for and connect the bound Bluetooth device. After successful connection, the app

will automatically enter the "Measurement" interface.

Shenzhen Linshang Technology Co., Ltd.

3/12/2022 Page 11 of 13

Measurement interface

3. Measuring interface

(1) Bluetooth connection status

The APP is connected successfully, the upper right corner of the interface shows "Connected", and the

APP is disconnected, showing "Not connected". When not connected, tap it, and the APP will

automatically reconnect the bound device.

(2) Data group modification operations

Click the data group name, the interface pops up, you can modify the name. Click the quantity area to

modify the amount of test data in the data group.

(3) Statistical information

The statistical information area displays the max. value, min. value, average value and standard

deviation of the measured data.

(4) Upper and lower limit setting

Set the upper and lower limits, which are used to judge whether the measured value is qualified.

(5) Instrument information

Shenzhen Linshang Technology Co., Ltd.

3/12/2022 Page 12 of 13

Display instrument setup material, unit, connected probe type.

(6) Create groups

Click Create Groups icon to automatically save the previous group and generate a new group.

(7) All groups

ClickAll Groups icon to select a set of data for open and delete operations.

(8) Share

Click the Share icon, enter the file name first, choose one of the four file formats of PDF, PNG, CSV and

TXT, and then share the file with your friends through QQ, WeChat, etc.

(9) Delete

Click the Delete icon and ask "Clear all historical records?", select “Cancel” to return, and select “OK” to

delete all measured values. You can also delete a single record in the measurement list.

(10) Measurement records

Displays the total number of current groups and the number measured.

4. APP measurement

Every time the instrument measures, the measured value will be automatically uploaded to theAPP, and

the APP will display the measured value in the form of a list on the measurement interface and judge

whether it is qualified or not.

5. Set up

Set theAPP measuring sound, alarm sound and testing vibration, vibration alarm.

VII. Attentions

1. The surface of the test object shall not be too rough,and it needs to be flat, smooth, free of oil and

grease, transmitting a metallic luster.

2. The minimum mass of the test object is 5Kg, and the minimum thickness is 25mm. For objects whose

weight and thickness do not meet the requirements, the test must be coupled with solid bracing.

3. The maintenance of the impact device.After using the device about 1000-2000 times, the user needs

to use a nylon brush to clean the instrument's conduit and impact body. When cleaning, the user

needs to unscrew the support ring of the catheter first, then remove the impact body, insert the nylon

brush into the catheter in a counterclockwise direction, then pull out the bottom and repeat five times,

and finally put the impact body and support ring.

4. After use, the impact body should be loosened.

5. The use of various lubricants is strictly prohibited in the impact device.

Shenzhen Linshang Technology Co., Ltd.

3/12/2022 Page 13 of 13

6. When measuring, the distance between any two indentations should not be less than 3mm, and the

distance between the center of the indentation and the edge of the object to be measured should not

be less than 5mm.

7. When the device displays “Low Battery”, batteries should be replaced.

VIII. Packing list

No.

Product Name

Quantity

Unit

1

Leeb Hardness Tester Host

1

Set

2

Leeb Hardness Tester Probe

According to the numbers of

probe ordered

3

Bluetooth Printer

According to the numbers of

printer ordered

4

Standard Leeb hardness block

1

pcs

5

Nylon Brush

1

pcs

6

Small support ring

1

pcs

7

1.5V AA alkaline battery

2

pcs

8

User Manual

1

pcs

9

Certificate / Warranty card

1

pcs

IX. Service

1. The gauge has one-year warranty. If the gauge works abnormally, please send the whole gauge to

our company for maintenance.

2. Provide users with spare parts and lifelong maintenance services.

3. Provide the users with the gauge calibration service.

4. Free technical support for the long term.

Manufacturer: Shenzhen Linshang Technology Co., Ltd.

Website: www.linshangtech.com

Service hotline: +86-755-86263411

Email: sales21@linshangtech.com

Table of contents

Other LINSHANG Test Equipment manuals

Popular Test Equipment manuals by other brands

Allied Radio

Allied Radio KNIGHT VTVM instruction manual

Rigol

Rigol DS6000 Series Service guide

MULTI MEASURING INSTRUMENTS

MULTI MEASURING INSTRUMENTS M-1800 instruction manual

HVTest

HVTest HTZZ-1A manual

Sanwa

Sanwa HG561H instruction manual

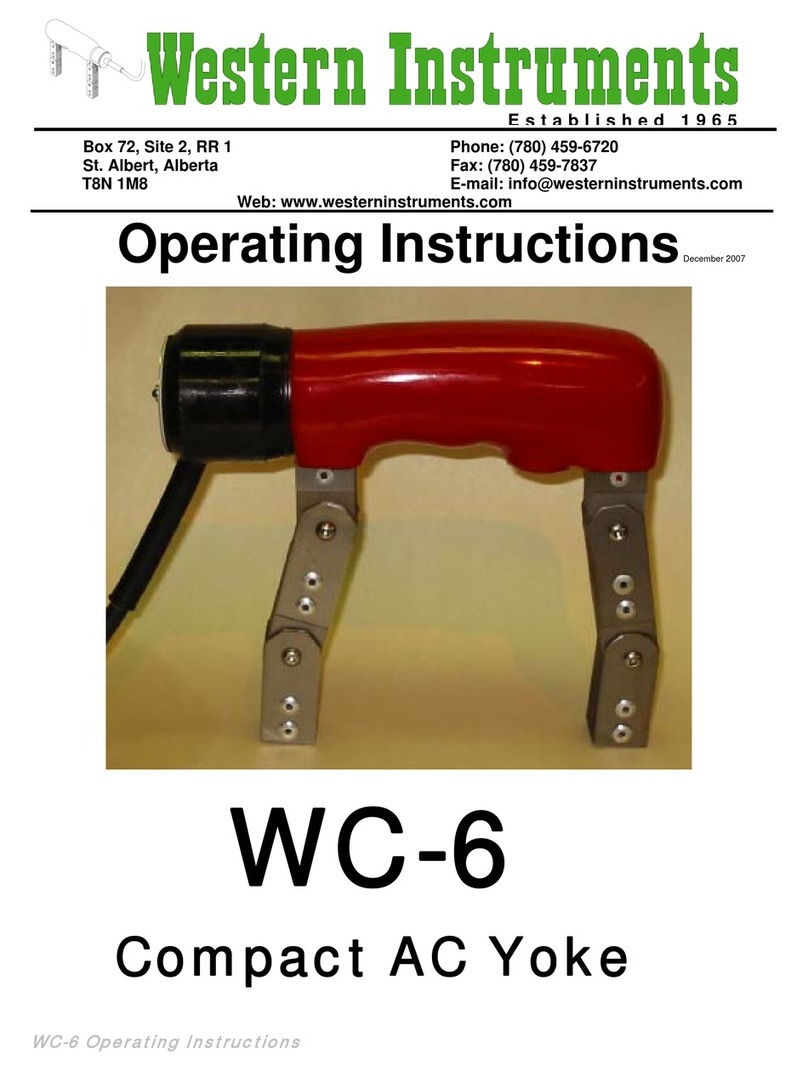

Western Instruments

Western Instruments WC-6 operating instructions