A5S1-n-Manual_EN_Rev02 2021_JAN_19 Page 2 of 36

Table of Contents

Contents Page

Table of Contents........................................................................................................................................................2

1General Information ...........................................................................................................................................3

1.1 List of Figures..............................................................................................................................................3

1.2 List of Abbreviations ....................................................................................................................................4

1.3 Application characteristics...........................................................................................................................5

1.4 Mounting of the Sensor ...............................................................................................................................5

1.4.1 Notes on Pole Wheel..........................................................................................................................6

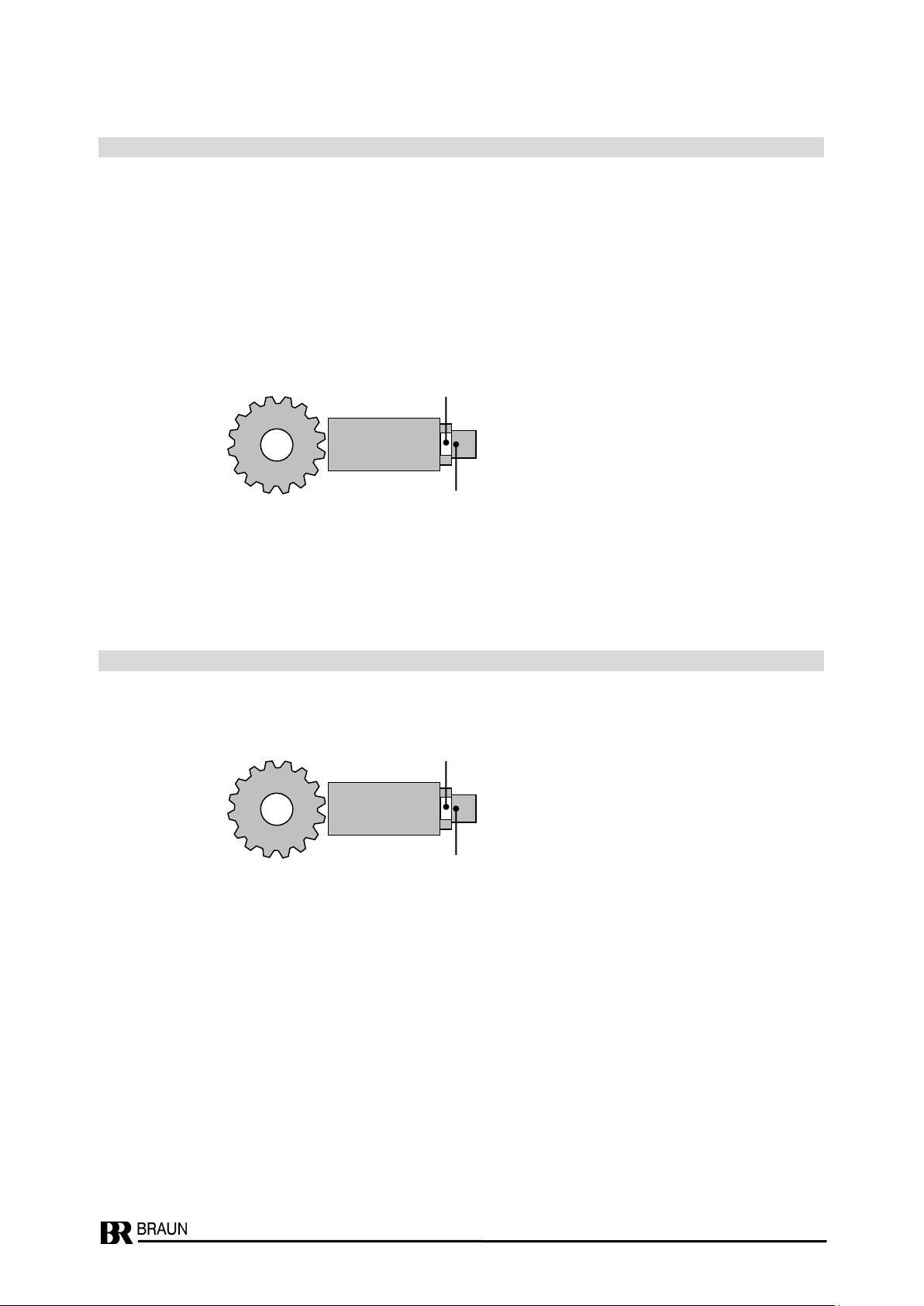

1.4.2 Positioning of Sensor..........................................................................................................................6

1.4.2.1 Alignment of Sensor.......................................................................................................................6

1.4.2.2 Recommended Air Gap..................................................................................................................7

1.4.3 Maximum fastening torques / wrench sizes / thickness of BRAUN nuts.............................................7

1.5 Connection (pin assignment resp. wire assignment) ...................................................................................8

1.6 Arrangement of Pins in Sensor Plug ...........................................................................................................8

1.7 Signal Transmission ....................................................................................................................................9

1.8 Direction of rotation signal for sensor series A5S1DD3…-n / A5S1DS3…-n.............................................10

1.9 Speed signal f2 (phase shifted) for sensor series A5S1DD4…-n / A5S1DS4…-n.....................................10

1.10 Level and shape of the output signal.........................................................................................................11

1.11 Ordering Key for Sensors of A5S1…-n Series...........................................................................................12

1.12 Safety Data................................................................................................................................................13

1.13 General Certificates / Approvals ................................................................................................................13

1.13.1 Certification IEC 61508:2010; SIL 3..................................................................................................13

1.13.2 Certification DIN EN ISO 13849-1:2016; PLe; Kat. 3........................................................................13

1.13.3 Certification DIN EN ISO 13849-2:2012; PLe; Kat. 3........................................................................13

1.13.4 Certification IEC 62061:2015; SILCL 3 ..............................................................................................13

1.13.5 SIL 3 Certificate ................................................................................................................................14

1.13.6 EU Declaration of Conformity ...........................................................................................................15

2Hazardous protection ......................................................................................................................................16

2.1 Relevant technical Data for Hazardous Area.............................................................................................16

2.2 ATEX Certification of the Input Circuit .......................................................................................................16

2.3 Explosive relevant Certificates / Approvals................................................................................................16

2.3.1 ATEX ................................................................................................................................................16

2.3.2 IECEx ...............................................................................................................................................16

2.3.3 USA (NEC) and Canada (CEC) ........................................................................................................16

2.3.4 EAC Ex.............................................................................................................................................16

2.3.5 ATEX Type Examination Certificate ..................................................................................................17

2.3.6 IECEx Certificate of Conformity ........................................................................................................20

2.3.7 NEC/CEC Certificate of Conformity ..................................................................................................26

2.3.8 EAC Ex TR CU Certificate ................................................................................................................28

3Safety Notes for Installation and Operation...................................................................................................32

3.1 General Instructions ..................................................................................................................................32

3.2 EMI............................................................................................................................................................32

3.3 Safety note about metallic abrasion in the machine ..................................................................................32

3.4 Safety Notes on Installation.......................................................................................................................32

3.4.1 Initial Commissioning and Installation...............................................................................................32

3.5 Safety Notes on Operation ........................................................................................................................32

3.5.1 Machine Maintenance or Overhaul...................................................................................................32

4Technical Specifications..................................................................................................................................33

4.1 Conformity to Standards............................................................................................................................33