All TESA Micro-hite plus M of the latest generation

are different from the other height gauges in that

they have exceptional metrological capabilities and

can be used intuitively with ease. The unique and

revolutionary rotary power control combines the

speed of a manually operated height gauge with the

precision and easy handling of a motorised one.

Each of them incorporates a number of new fea-

tures for which patents are pending.

These height gauges are specially designed for

measuring lengths in the form of internal, external,

step, height or depth dimensions as well as dis-

tances. Their concept also permits, for instance,

deviations from straightness and perpendicularity

to be measured.

Every TESA Micro-hite plus M is mechanically

adjusted at our premises based on a TESA’s

patented system, thus allowing random errors in

perpendicularity to be quickly and easily detected

using a dial test indicator.

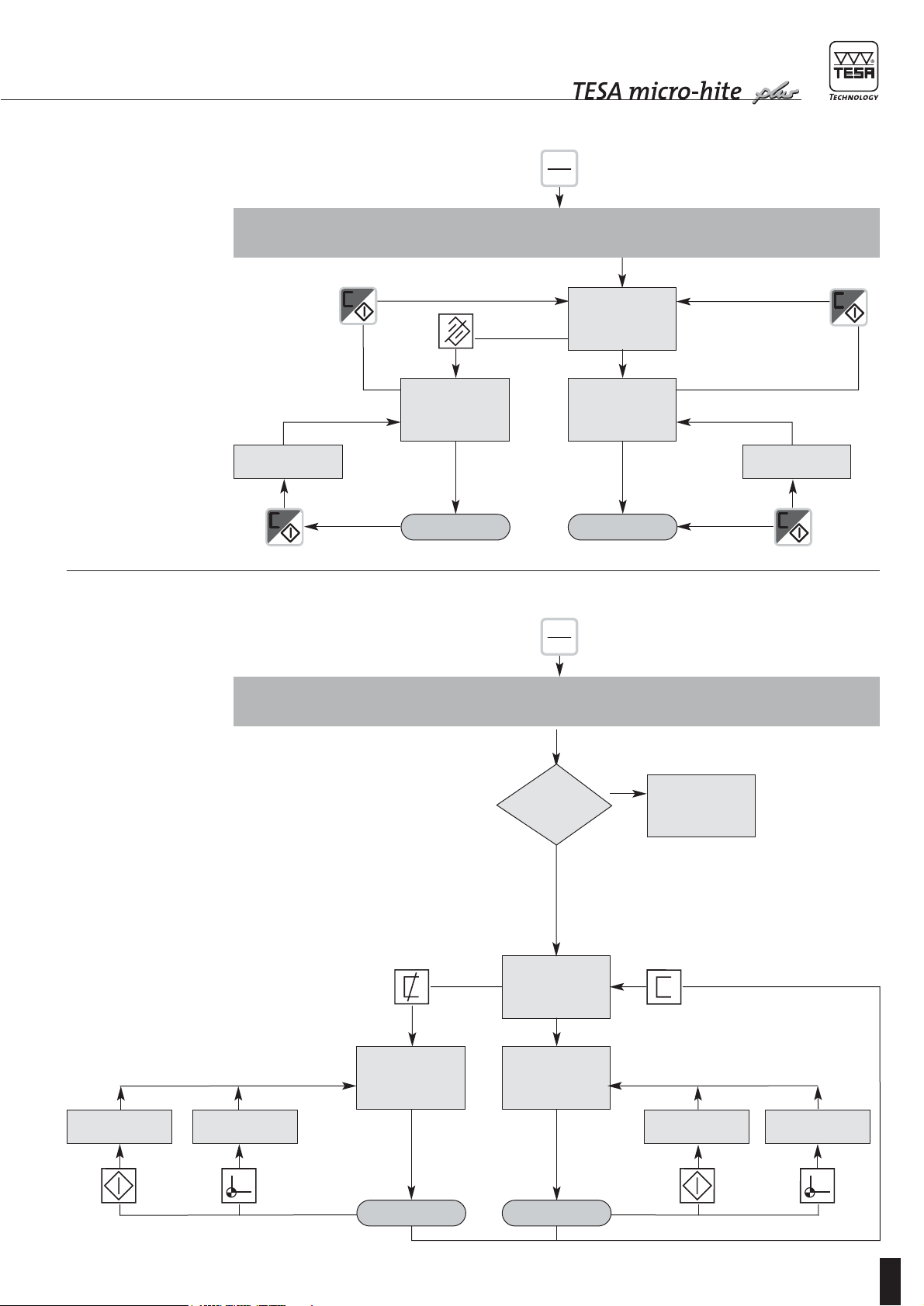

Value processing is ensured via the control panel.

With their modular concept, TESA Micro-hite plus

M offer an individual solution to each measuring

application.

The Power Panel plus M, which may be provided

with or without built-in printer, can be used besides

the 1D control panel – thus enabling single or two

coordinate measurements to be carried out as well

as bore position to be determined, both in polar and

rectangular coordinates. Furthermore, this panel

can measure straightness and perpendicularity

along with angles. It also allows direct connection

ofa measuringinstrument fittedwith anRS232 dig-

ital output.

The heavy cast-iron base features three resting

points precisely ground to ensure high stability.

Once integrated, the electric pump generates the

air-cushion so that your height gauge can easily be

moved across the surface plate.

The rigid column under the housing includes the

guiding part that is rigorously straight and perpen-

dicular to the base. The patented opto-electronic

system measures any head displacement.

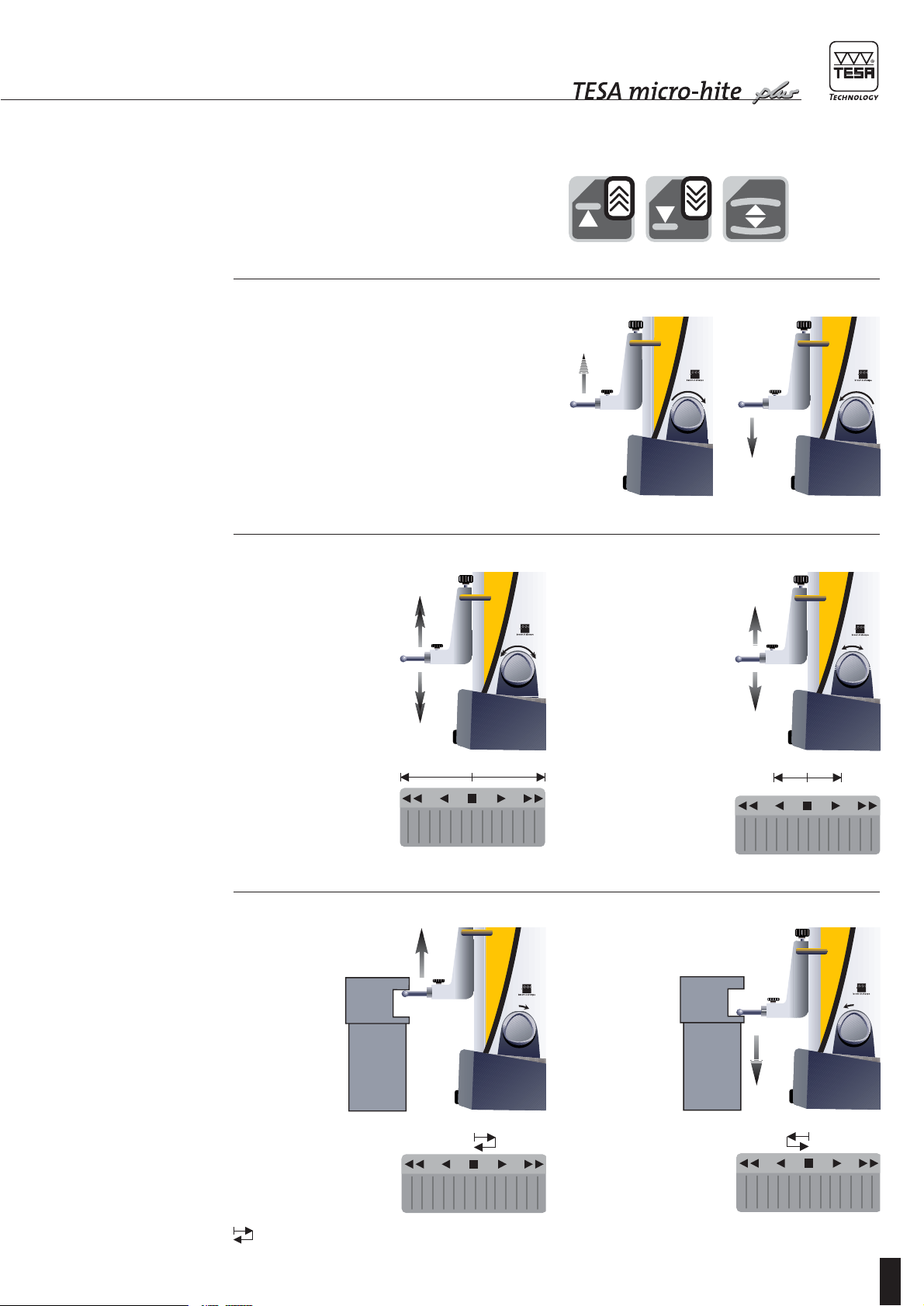

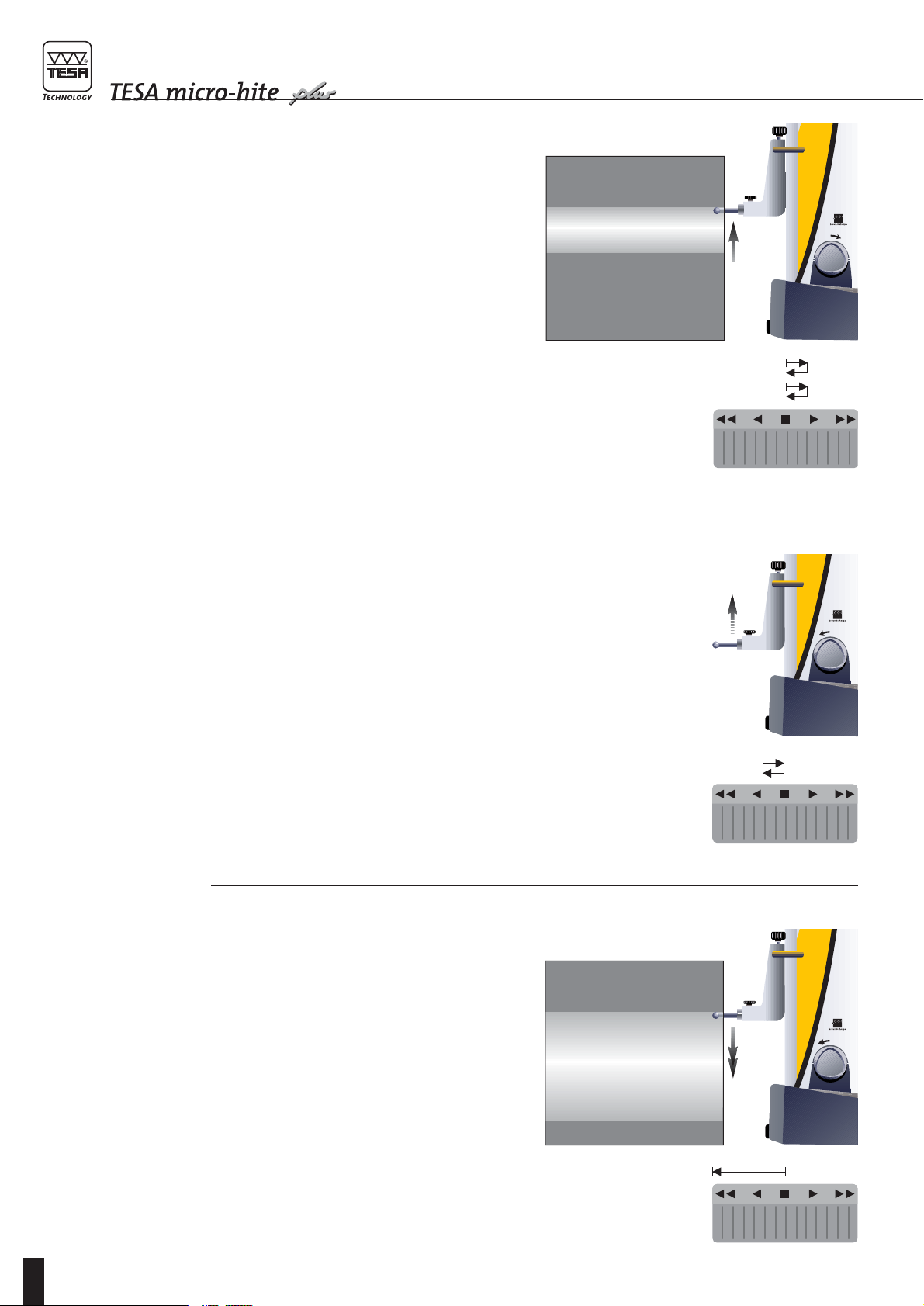

Value acquisition is very simple and reliable. Rotating

the power control or activating the appropriate func-

tion key causes the insert to move to the point to be

probed automatically. The measured value is then

captured after a wait for stabilisation. A constant

measuringforceis ensured bythe mechanicalfriction

release mechanism, which has been specially devel-

oped for this purpose. An acoustic signal confirms

the capture of the measured values, which are dis-

played at once and further transferred via the RS out-

put provided they are judged to be correct.

Round-shaped cylindrical surfaces (e.g. bores or

shafts) can equally be inspected easily and reliably

through automatic detection of the culmination

point.

The computer-aided value correction enhances the

accuracy of every TESA Micro-hite plus M even fur-

ther. The correction values stored in the electronics

compensate for the bias errors when measuring

lengths.

Continuous mains independent operation is

ensured by the rechargeable battery pack with no

cumbersome cables or power cord to hinder the

operator.

1 GENERAL FEATURES

5