Table of contents

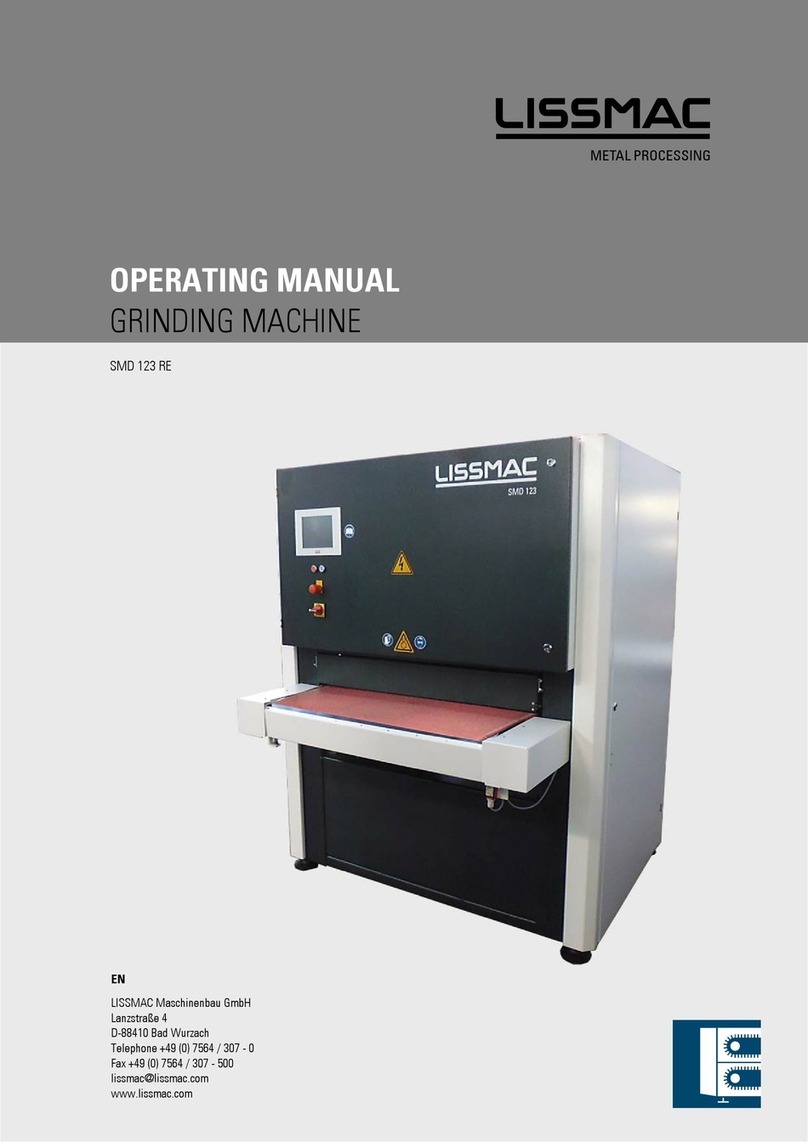

4 Grinding machine SMD 133 DRE /-60

Table of contents

1About this manual ........................................................................................6

1.1Target group..........................................................................................6

1.2Additional documents..............................................................................6

1.3Presentation of warnings..........................................................................7

1.4Additional representations........................................................................7

2Safety .........................................................................................................8

2.1Safety instructions..................................................................................8

2.2Organisational measures..........................................................................8

2.3Personnel selection and qualifications.........................................................8

2.4Transport ..............................................................................................9

2.5Normal operation ...................................................................................9

2.6Maintenance, Service and Troubleshooting ..................................................9

2.7Safety instructions for special types of dangers...........................................10

2.7.1Electric power .........................................................................10

2.7.2Dust .....................................................................................10

2.7.3Fire hazard..............................................................................10

2.7.4Explosion hazard ......................................................................11

2.7.4.1Description of explosion hazard .........................................11

2.7.4.2Division of zones ............................................................11

2.8Symbols on the machine ........................................................................12

3Product description....................................................................................13

3.1Appropriate usage ................................................................................13

3.2Technical data .....................................................................................14

3.3Type plate...........................................................................................16

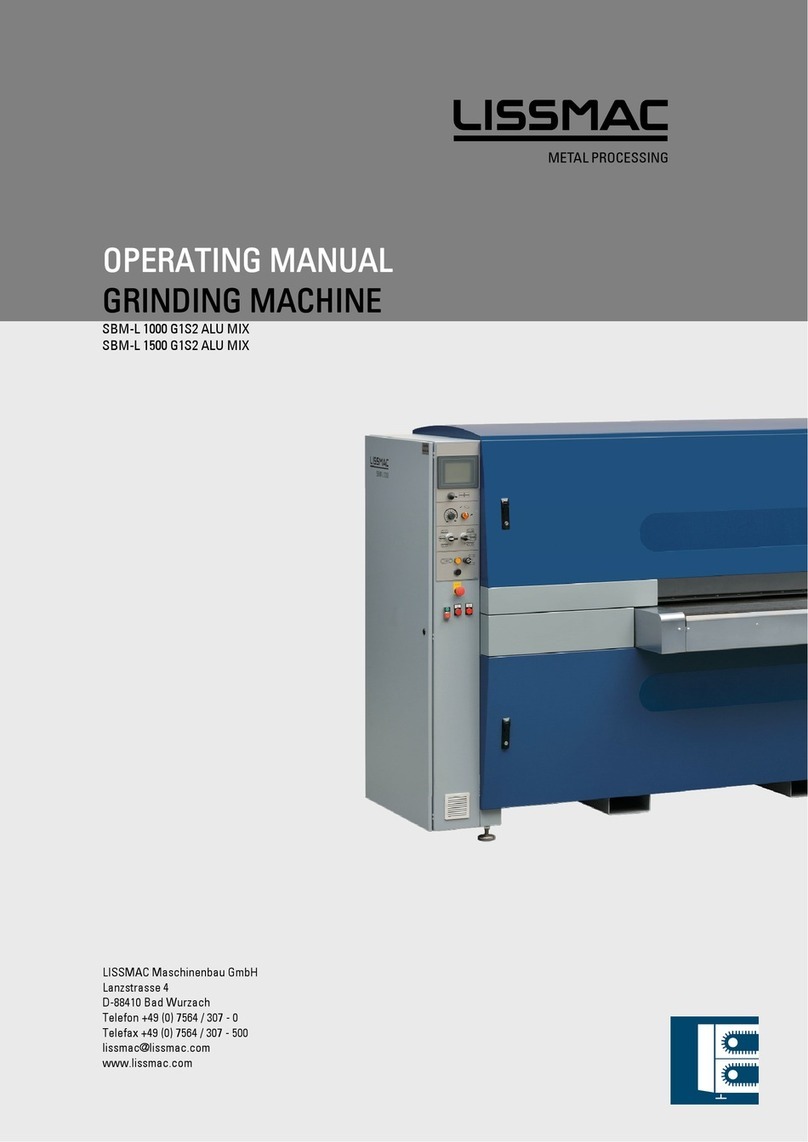

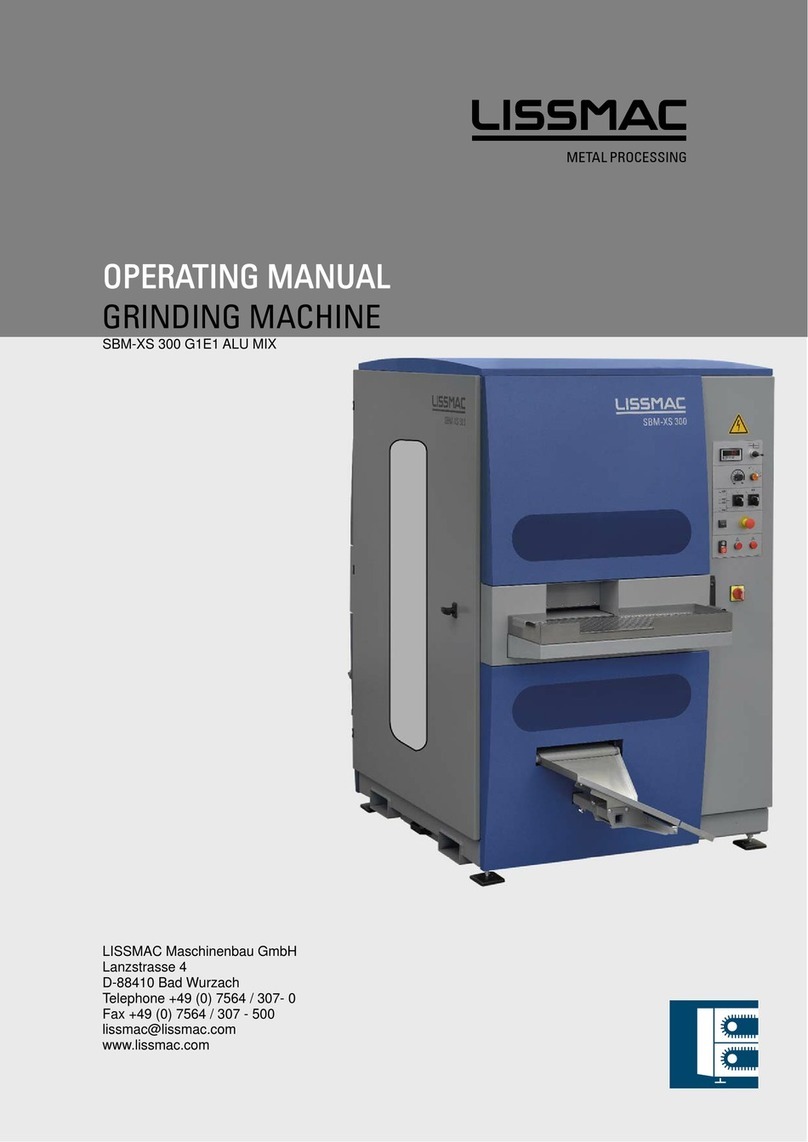

3.4Set up of grinding machine .....................................................................17

3.5Machining units ...................................................................................19

3.6Control elements ..................................................................................20

3.7Function ............................................................................................22

3.8Safety equipment .................................................................................23

4Preparation for use ....................................................................................24

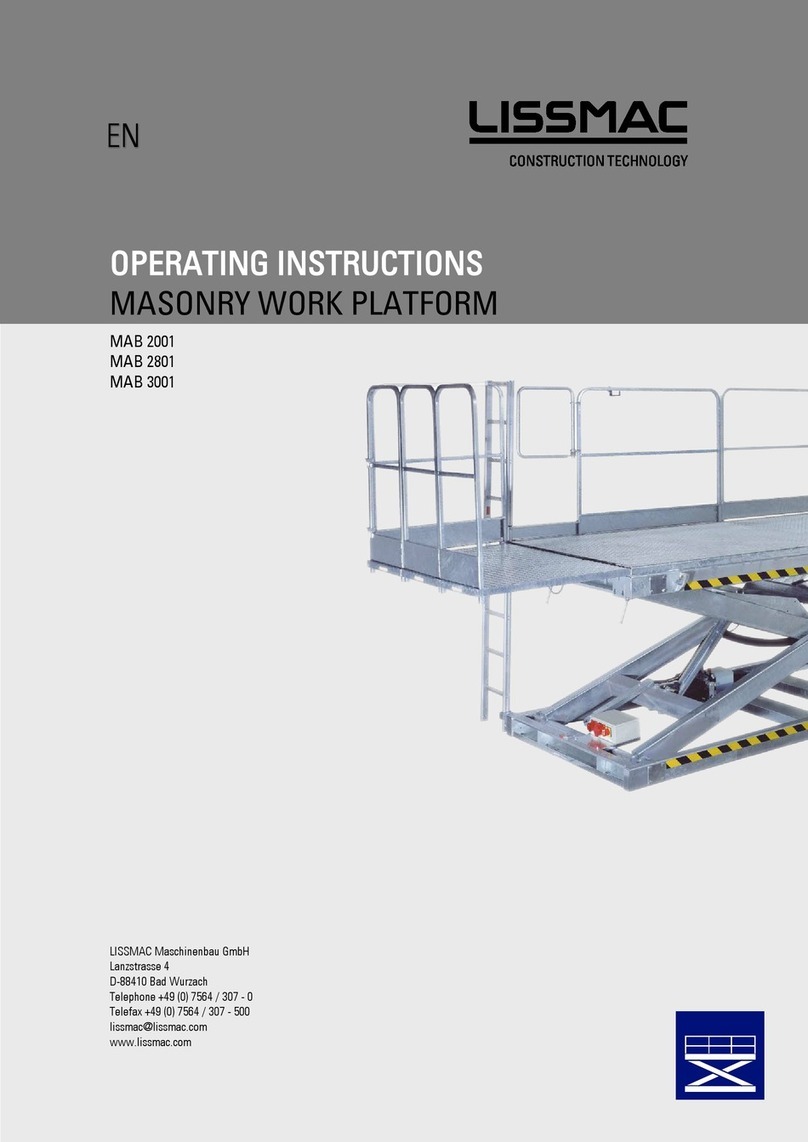

4.1Transporting the machine .......................................................................24

4.2Storing the machine ..............................................................................25

4.3Installation and unit ..............................................................................25

4.3.1Installing machine ....................................................................25

4.3.2Connecting the machine ............................................................26

4.3.3Connecting the extractor system..................................................27

5Operation ..................................................................................................28

5.1Control elements ..................................................................................28

5.2Operating the control and display field ......................................................29

5.2.1Screen set up ..........................................................................29

5.2.2Screen symbols........................................................................30