X270 (ZADI)

by

LockTech

www.locktech.biz

accureader@locktech.biz

Thank you for purchasing the AccuReader

wafer reading system by LockTech. This system will

allow you to read the Zadi (X270) ignition and other

locks without the removal of the ignition or other locks.

Following a few simple steps it takes only minutes to

read the depths for each cut in each position for a

complete key.

The AccuReader works on the process of

elimination to decipher the correct depths of the lock.

By checking the deepest cut first you eliminate what

the cuts are not. Therefore it is essential to always

read depth slide #4/3 first.

The AccuReader key is designed to be used

for wafer positions 4-7 on one side of the key and

wafer positions 1-3 on the opposite side of the key. It

is recommended to start from the rear of the lock and

work outward to the number 1 position.

Please take the time to familiarize yourself

with the tools and verify all pieces are accounted for

from the list of contents below:

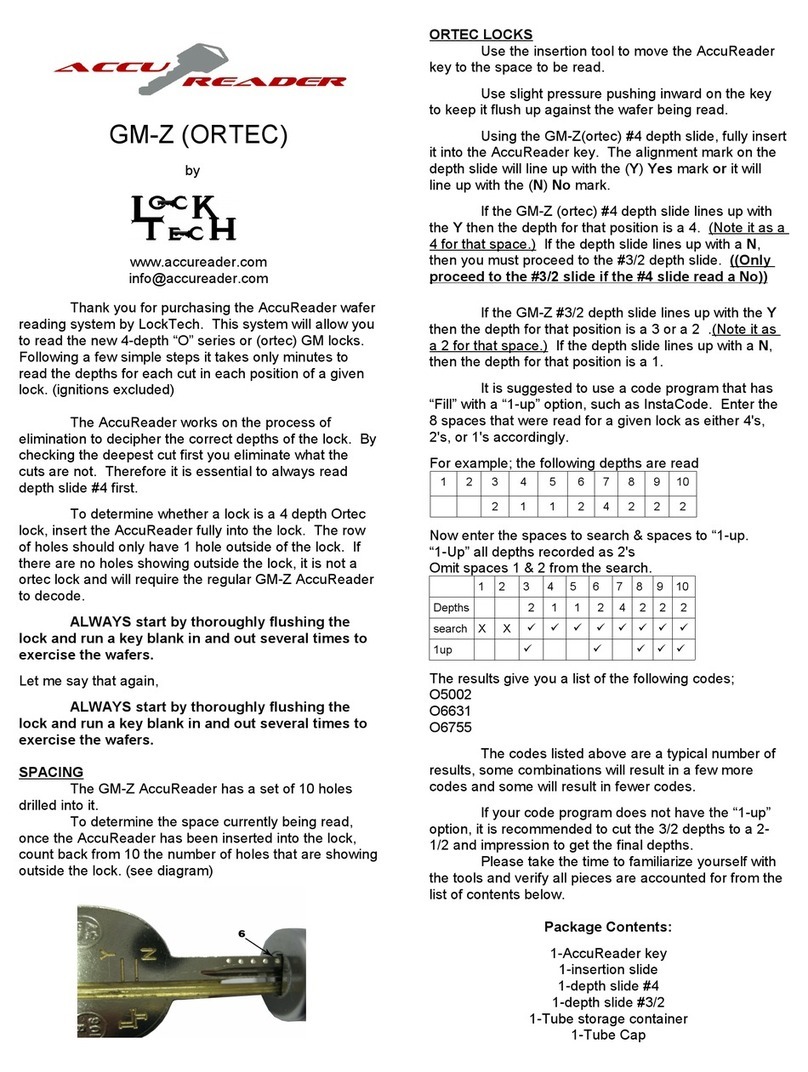

Package Contents:

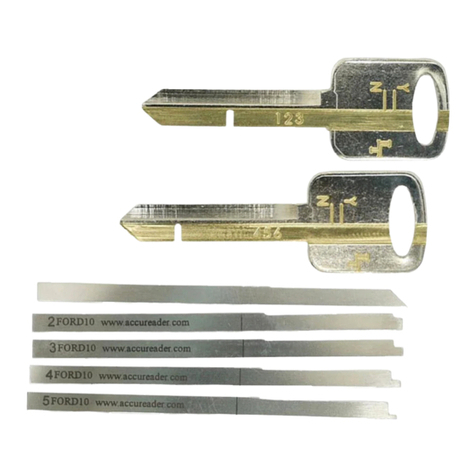

1-AccuReader key

1-insertion/release slide

1-depth slide #4/3C

1-depth slide #4/3OS

1-depth slide #2C

1-depth slide #2OS

1-Tube storage container

1-Tube Cap

USING THE ACCUREADER on CENTERED

KEYWAYS

1) Always thoroughly clean the lock with a electronics

safe cleaner to free any potentially stuck wafers.

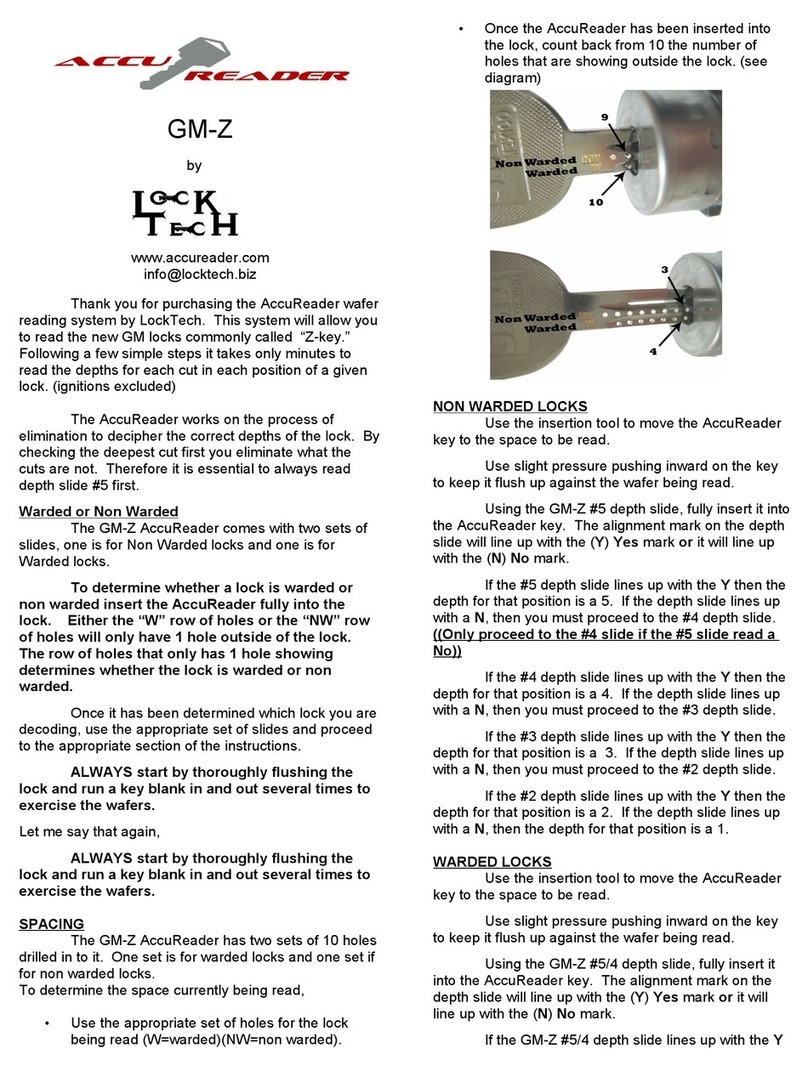

2) Use the alignment holes through the AccuReader

key to assist in judging the distance from one wafer

position to the next. CENTERED Zadi keyways have

opposing wafers.

3) Place the insertion/release slide in the slot on the

AccuReader key. Fully insert the AccuReader key into

the keyway and remove the slide. The AccuReader

key should trap a wafer without pulling out any. If the

AccuReader key pulls out some before trapping a

wafer, flip the AccuReader key over and resinsert fully

to trap wafer #6. It is now ready to read the #6 wafer.

4) Always start reading with the #4/3C depth slide

tool, and then proceed to #, if necessary. Fully

insert the depth slide into the AccuReader key. The

alignment mark on the depth slide will line up with the

(Y) Yes mark or it will line up with the (N)No mark.

a) If the #4/3C depth slide lines up with the Y

then the depth for space #6 wafer is a 4 or 3. If the

depth slide lines up with a N, then you must proceed to

the #2C depth slide.

b) If the #2C depth slide lines up with the Y

then the depth for space #6 wafer is a 2. If the depth

slide lines up with a N, then the depth for space #6 is a

1.

c) Repeat steps a & b for each even wafer

position reading 6, 4 & 2. Flip the AccuReader over

and read spaces 5, 3, & 1.

d) Cut all 1’s to 1’s, 2’s to 2’s and 4/3 depths to

a 3.5. The key should turn in the lock relatively easily,

do not force. Any spaces that marked should be

moved to a 4 depth and any spaces that did not mark

should be recut to a 3 depth.

e) You now have recorded all the positions to

make a complete key.

USING THE ACCUREADER on OFFSET KEYWAYS

1) Always thoroughly clean the lock with a electronics

safe cleaner to free any potentially stuck wafers.

2) Use the alignment holes through the AccuReader

key to assist in judging the distance from one wafer

position to the next. OFFSET Zadi keyways have

wafers only on one side.

3) Place the insertion/release slide in the slot on the

AccuReader key. Fully insert the AccuReader key into

the keyway and remove the slide. The AccuReader

key should trap a wafer without pulling out. If the

AccuReader key pulls out without trapping a wafer, flip

the AccuReader key over and resinsert fully to trap

wafer #6. It is now ready to read the #6 wafer.