Strike

Strike

Box

Jamb

P

L

E

A

S

E

R

E

C

Y

C

L

E

T

H

I

S

P

A

C

K

A

G

I

N

G

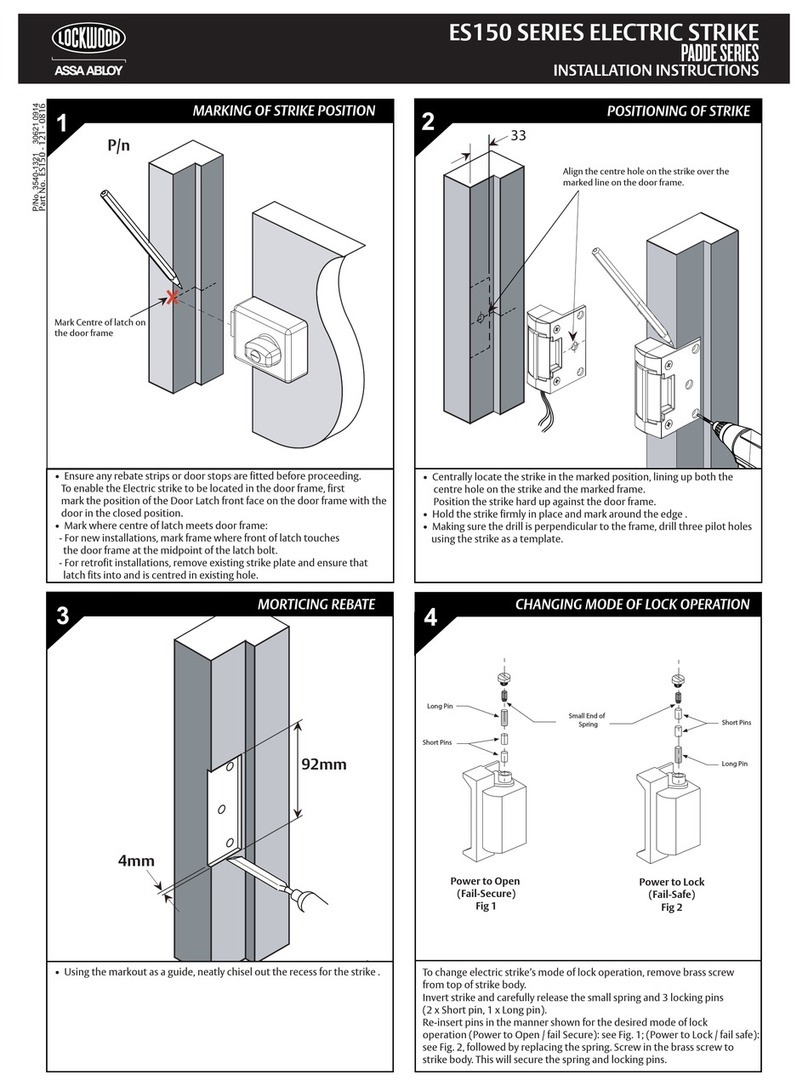

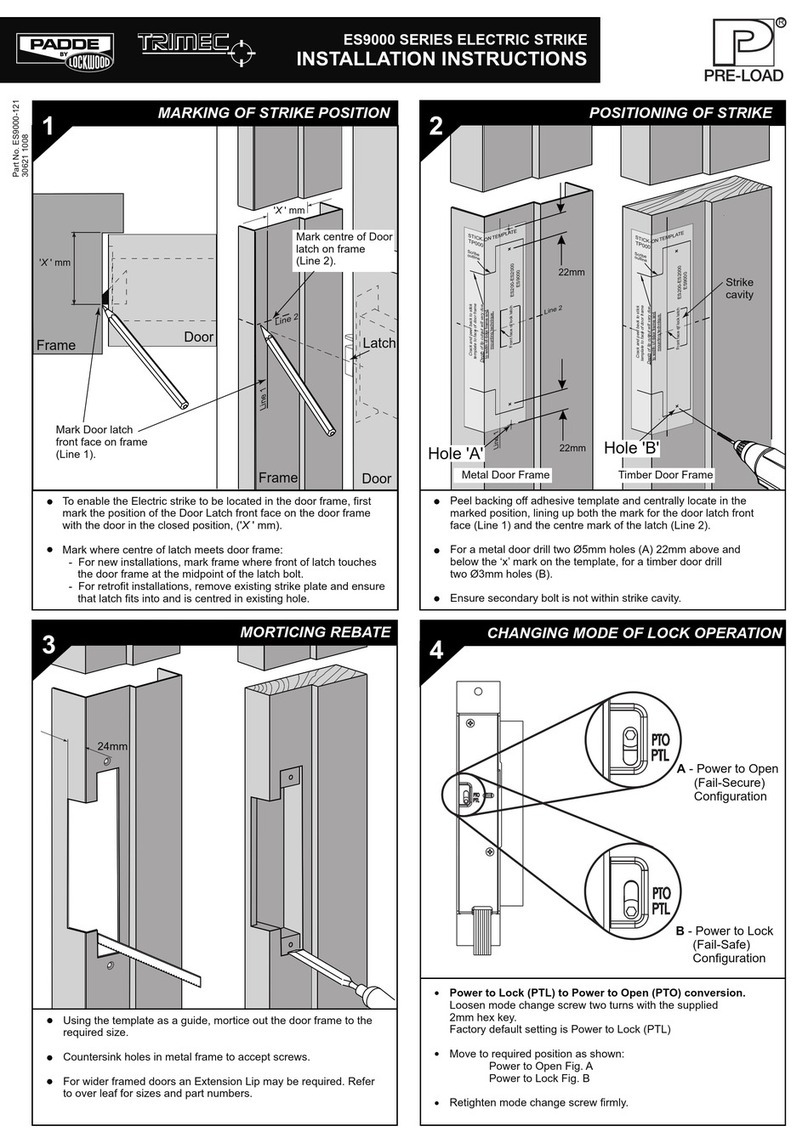

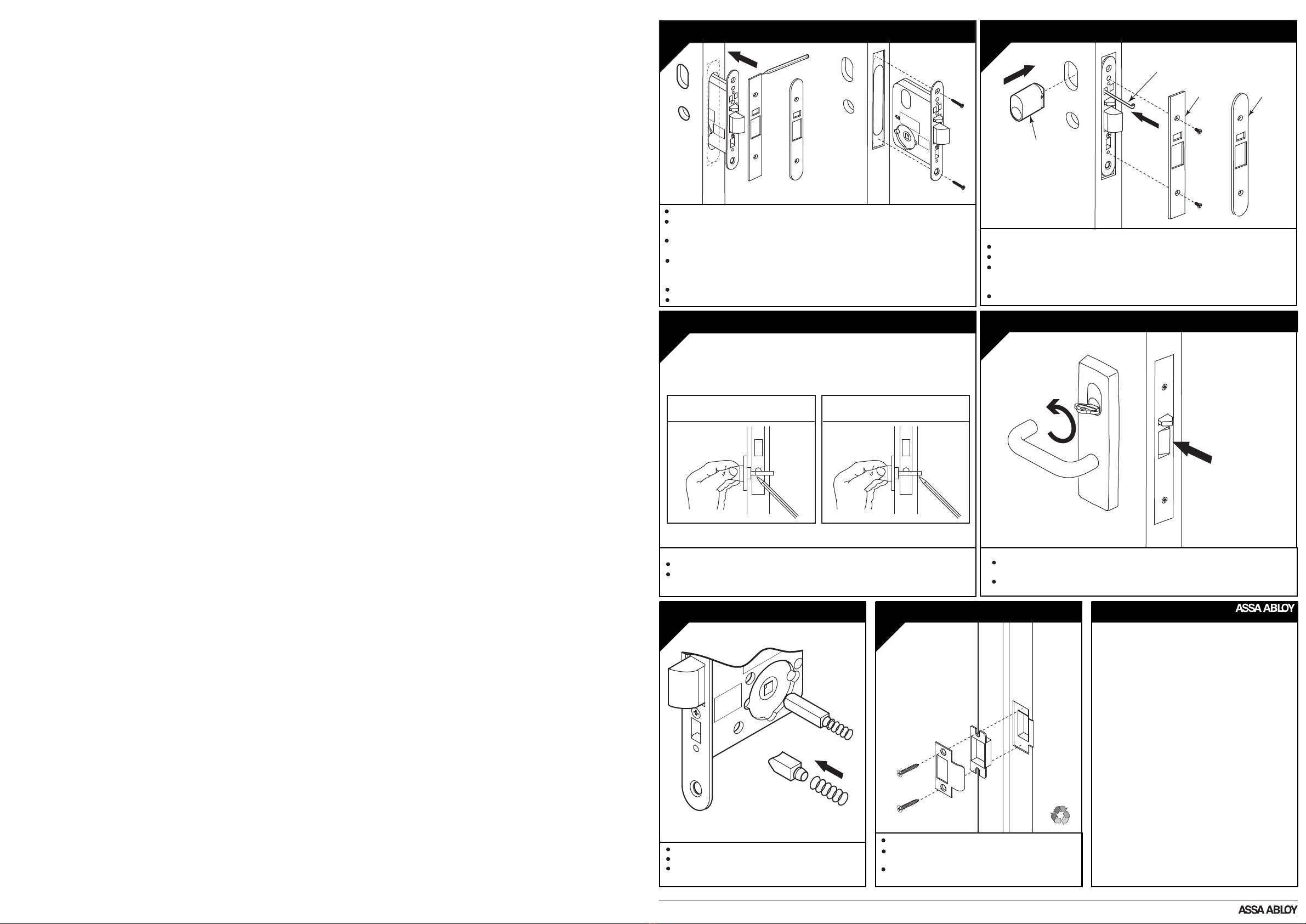

Mark out door frame for strike.

Mortice door frame for strike box and strike. Bolt

recess to be 15mm deep in door frame.

Screw strike and strike box to the door frame with

two screws supplied with mortice lock.

All locks are supplied with spindles.

Insert spindle(s) into lock, as required.

Assemble furniture as required. Ensure furniture is

not over-tightened.

9 LOCKS WITH SPINDLES 10 MOUNTING STRIKE LOCKWOOD GUARANTEE

7

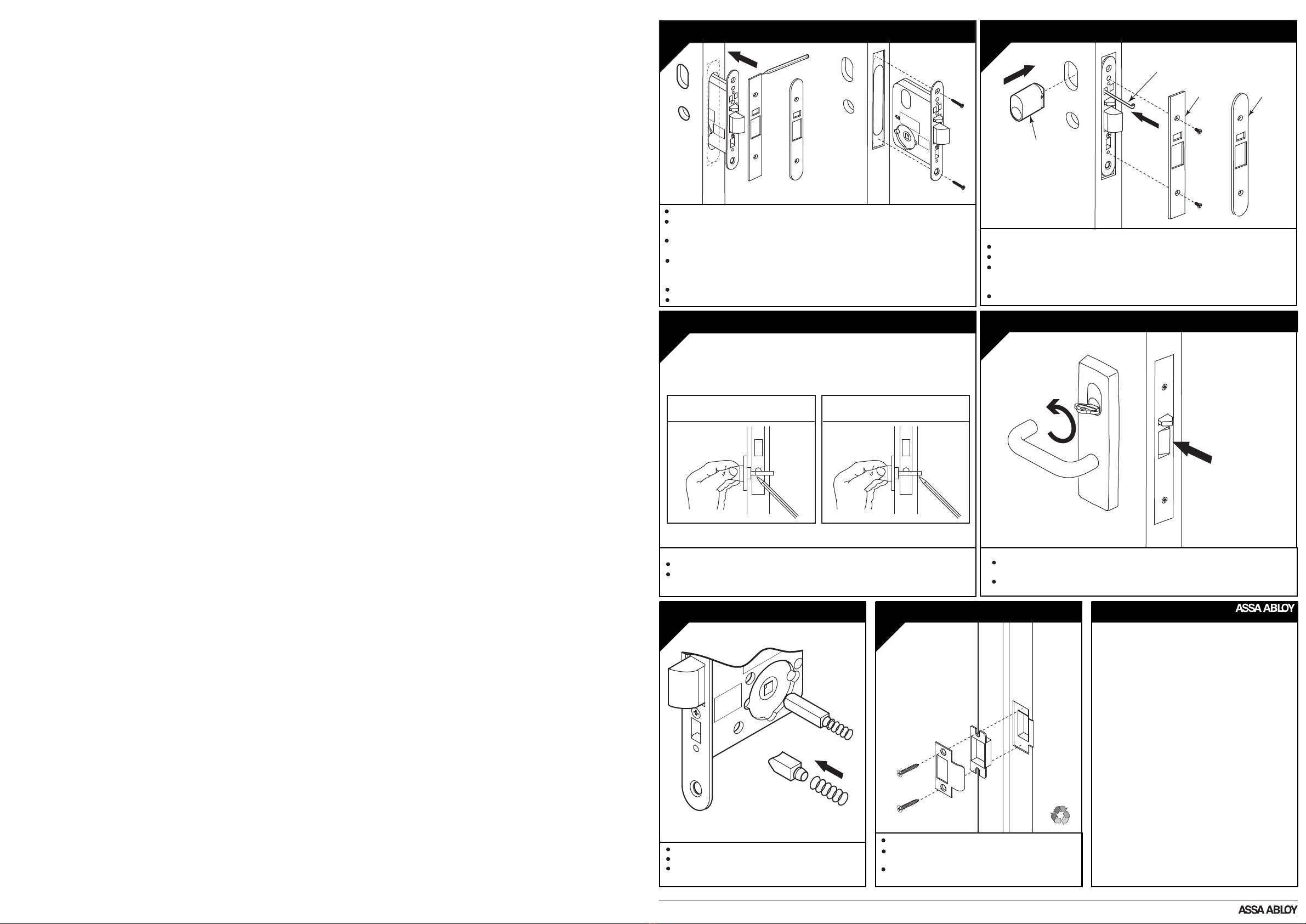

Mark and cut connecting bar as shown.

Turn knob to be in the vertical position when UNLOCKED.

LOCKS WITH TURNKNOBS

LATCHING OR

LOCKING TURNKNOB

EMERGENCY TURNKNOB

FUNCTION

IMPORTANT :

Attach spindle spring to rear

of spindle before assembling

ASSA ABLOY Australia Pty Limited, (“ASSA ABLOY”), guarantees its

products against defects in

workmanship

and materials. If within the

normal working life of a product it is found to be defective, ASSA

ABLOY

will supply the same or an equivalent product free of charge.

All electrical and electronic components used in Lockwood’s range

of products excluding batteries are guaranteed for a period of

12 months from the date of proof of purchase, unless otherwise stated.

ASSA ABLOY assumes no liability under this guarantee for the

following :

1. Improper installation or failure to follow fitting instructions.

2. Failure due to improper maintenance.

3. Failure due to fair wear and tear.

4. Indirect or consequential loss or damage.

5. Cost of removal and/or replacement.

6. Cost of freight and/or replacement.

7. The plated finishes Florentine Bronze, Architectural Bronze,

Polished Brass and Satin Brass are classified as soft finishes.

As deterioration is possible under some climatic conditions,

these finishes are excluded from this guarantee.

8. Any modification to a product as supplied, or repaired, unless

authorised by ASSA ABLOY.

9. Use of replacement part other than authorised parts.

10. Malfunction or failure of the product due to use of

non-genuine Lockwood parts.

11. Malfunction or failure of the product due to the use of

non-specified batteries.

Nothing in the Lockwood Guarantee excludes, restricts or modifies

any condition, warranty, right or liability implied or protected by law

where to do so would render the Guarantee, or any part of it, void.

ASSA ABLOY Australia Pty Limited, 50 Edward Street, Oakleigh VIC 3166, ABN 90 086 451 907 © 2006

An ASSA ABLOY Group brand

5 DOOR PREPARATION

Ease out mortice cavity where necessary. Clean out mortice before inserting lock.

Insert lock in mortice with Cover Plate on and scribe around Cover Plate for size of

recess, ensuring that no foreign matter finds it way into the lock mechanism.

Remove lock from mortice and chisel recess 4mm deep to receive both front

and cover plate. Cover plate must be flush with edge of door.

Ensure lock is removed from mortice cavity. Fold template along backset fold

line. Align EDGE A with bottom of cover plate recess. Establish holes required to

suit lock function, mark hole centres accurately, drill and clean holes.

Drill furniture holes as required.

Fasten mortice lock into door using mounting screws provided.

6

LOCKS WITH CYLINDERS

Place lock in mortice and insert cylinder.

Secure cylinder with retainer pin, ensuring pin is flush with front plate.

Install Cover plate and secure with 2 M4 screws provided to lock body.

LOCKS WITHOUT CYLINDERS

Install Cover plate and secure with 2 M4 screws provided to lock body.

LOCKS AND CYLINDERS

To activate HOLD BACK function, depress latchbolt with thumb and turn key

or turn knob.

To de-activate HOLD BACK function turn key or turn knob in opposite direction.

8 ACTIVATING HOLD BACK FUNCTION

Cover plate

(Square)

Cover plate

(Round)

Cover

plate

(Square)

Cover

plate

(Round)

Cylinder

retainer

pin

Cylinder

assembly