4Carbide Cutter OM

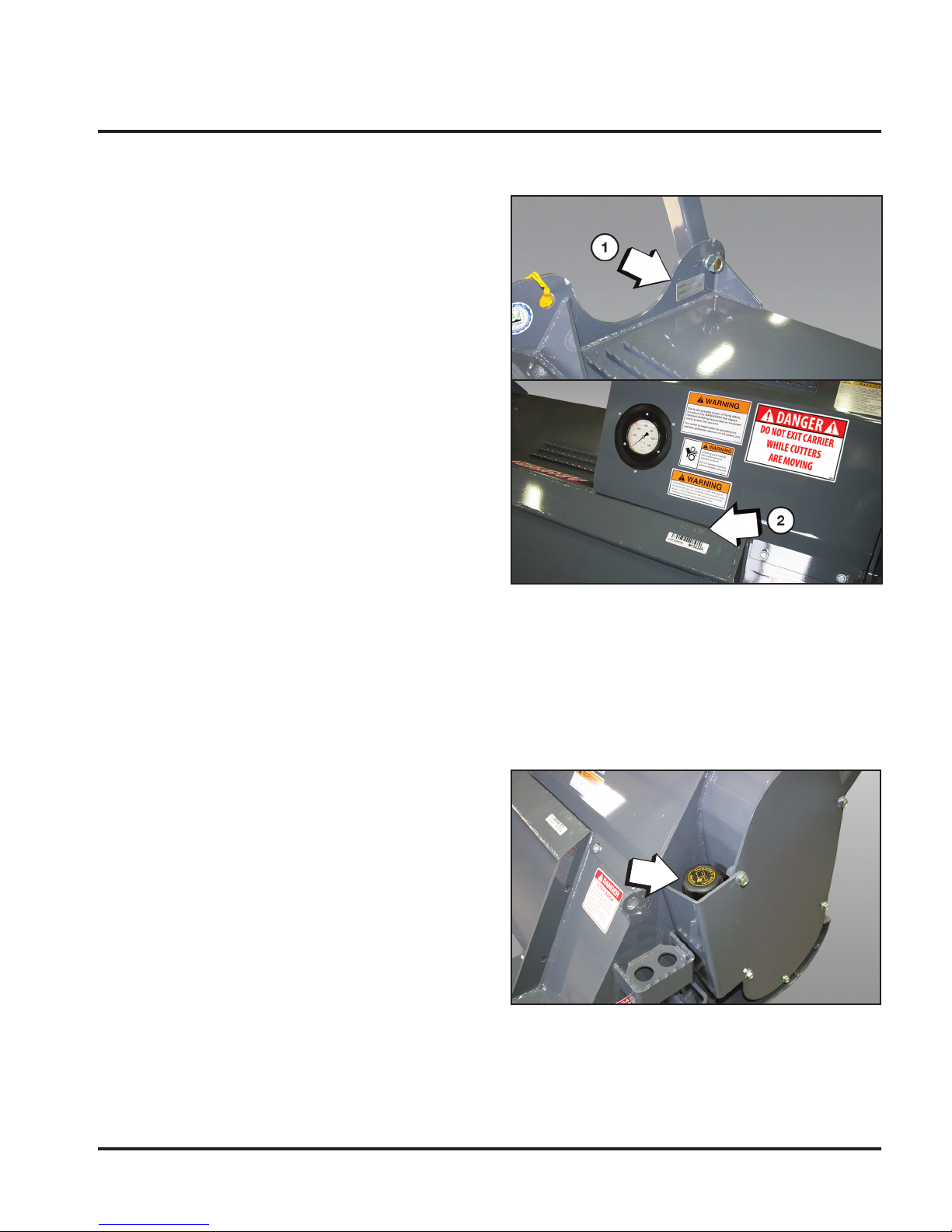

Mandatory Shut-Down Procedure

• Stop the machine and attachment on a level surface

and lower the attachment to the ground.

• Move throttle to idle position.

• Disengage all power to the attachment.

• Shut off engine and remove the key.

Wait until the rotor has stopped completely before

inspecting the attachment.

Safety Rules

These are general safety considerations. Additional

precautions may be necessary to operate your

machine in a safe manner. Be certain you are operating

your machine in accordance with all safety codes,

OSHA rules and regulations, insurance requirements

and local, state, and federal laws.

• Read and observe all warnings decals on the machine

before attempting to operate the attachment. Do not

attempt to operate this attachment unless all factory

devices and decals are in place. Keep safety decals

clean of dirt and grime. Keep all guards, shields and

decals in place.

• Remove from area of operation all foreign objects

such as bottles, rocks, wire, etc., that might become

tangled in the rotor, causing damage to the machine

or be thrown striking other objects.

• Do not allow any people and animals within 300 feet

of the machine and attachment during operation.

• Do not allow anyone to operate the attachment

until he or she has read the owner’s manual and is

completely familiar with all safety precautions. Keep

the work area clear of all unauthorized personnel.

• Do not allow persons under the influence of alcohol,

medications, or other drugs that can impair judgment

or cause drowsiness to operate or maintain the

machine.

• Always use an approved roll bar and seat belt for

safe operation. Overturning a machine without a roll

bar and seat belt can result in injury or death.

• Use the handholds and step plates when getting on

and off the machine to prevent falls. Keep steps and

platform cleared of mud and debris.

• Always have an operator in the machine while the

attachment is in operation. Never leave the machine

and attachment running and unattended.

• Operate the attachment only from the operator’s

seat.

• Keep your feet on the pedals, (floor plates) seat belt

fastened snuggly and seat bar lowered, (if equipped),

when operating the attachment.

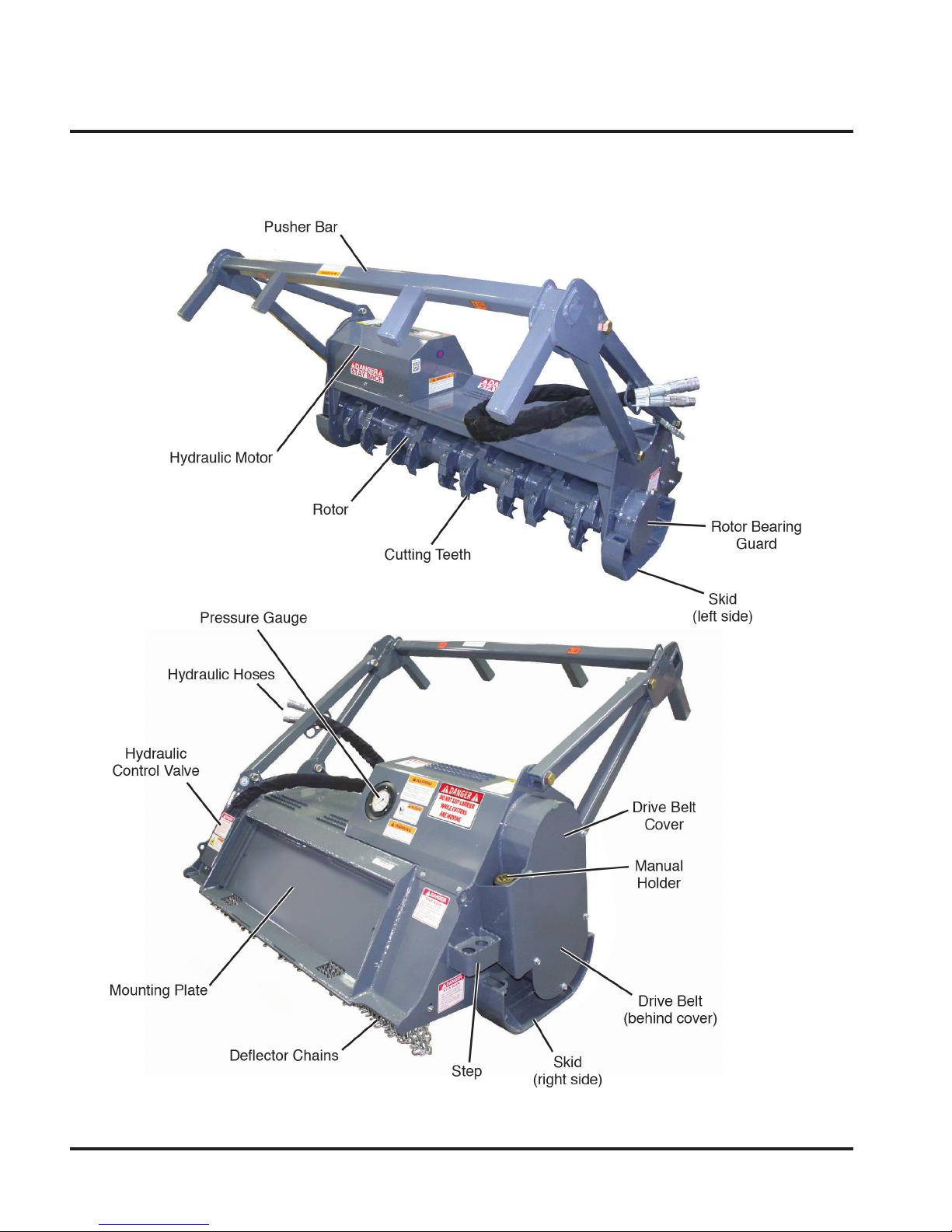

• The adjustable push bar could contact the machine

in some positions. Before starting the power unit,

set the push bar in the most forward position, then

slowly rotate the attachment back while an assistant

checks for clearance. Repeat this process in the

other settings to determine which positions are

usable with your machine.

• Never attempt to make any adjustments while the

attachment is running or the key is in the “ON”

position in the machine. Before leaving the operator’s

position, disengage power to the attachment, shut

off engine and remove ignition key.

• Disengage auxiliary hydraulics and place all machine

controls in neutral and engage the parking brake

before starting the engine.

• Become familiar with and know how to operate all

safety devices and controls on the machine and

attachment before attempting to operate. Know how

to stop the machine and attachment before starting

it.

• Repeated impact of the knives with hard objects can

cause excessive wear and damage to the skid-steer

or attachment. Be sure to maintain recommended

ground clearance as specified in this manual.

• Should excessive vibration occur, disengage the

auxiliary hydraulics immediately and shut off engine.

Do not continue to operate the attachment until the

problem has been determined and corrected.

• Do not start, operate, or work on this attachment until

you have carefully read and thoroughly understand

the contents of this manual and the operator’s

manual for your machine.

Safety Instructions