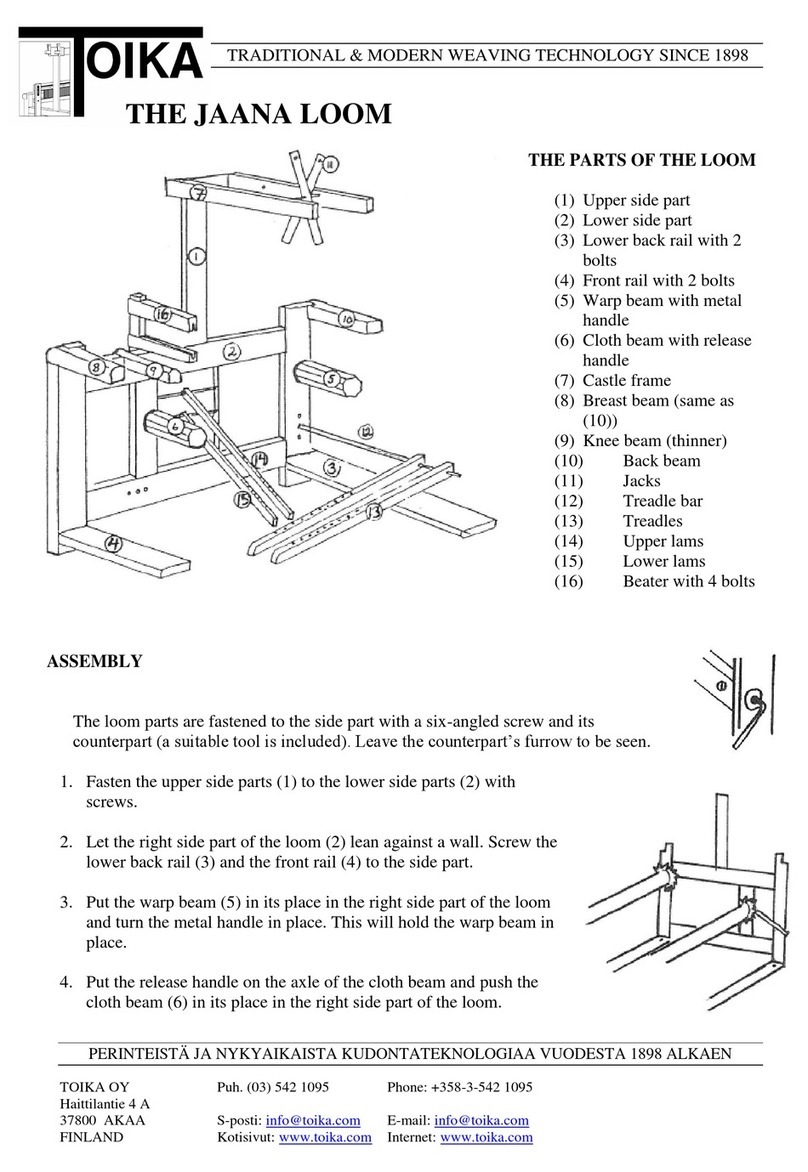

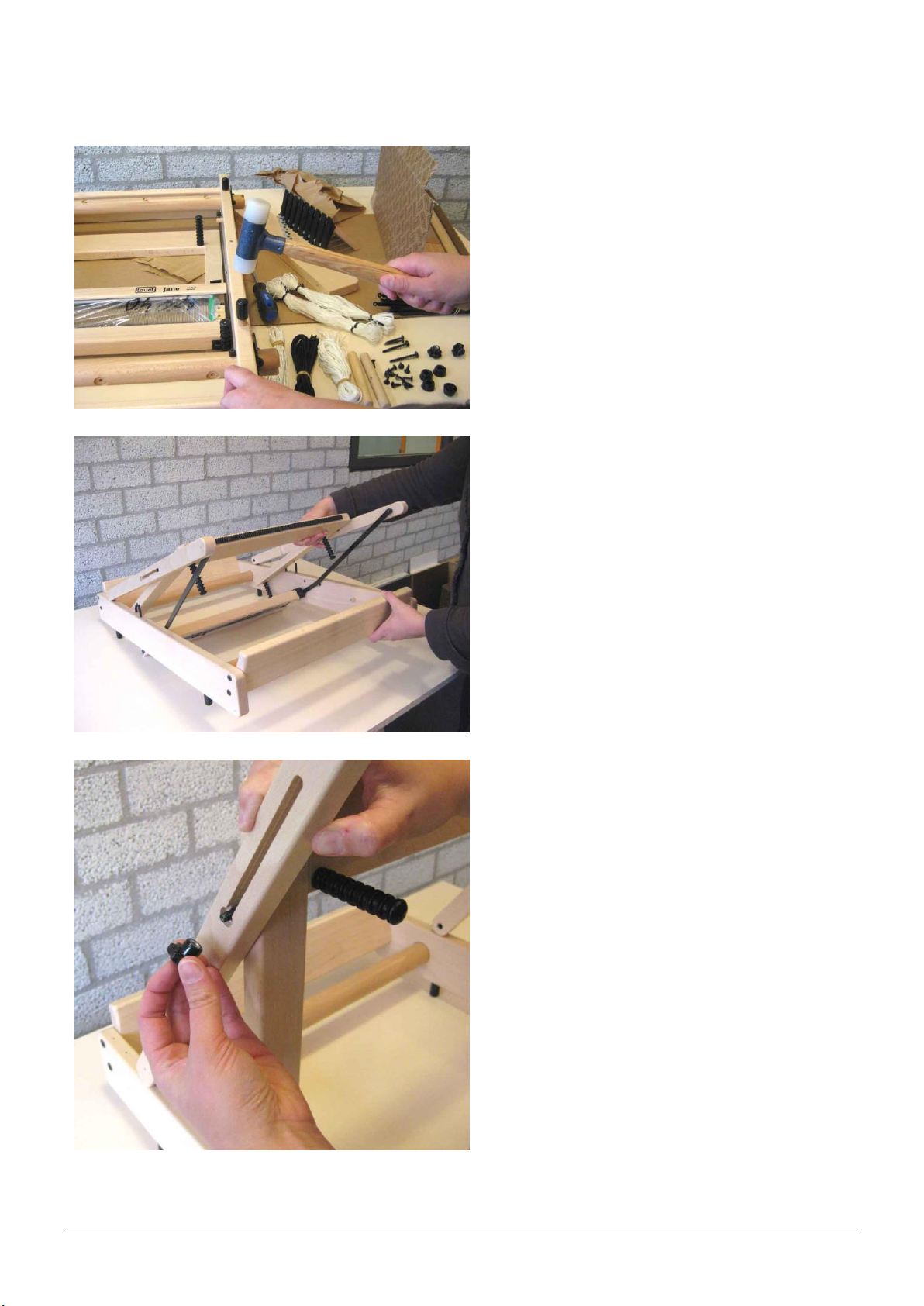

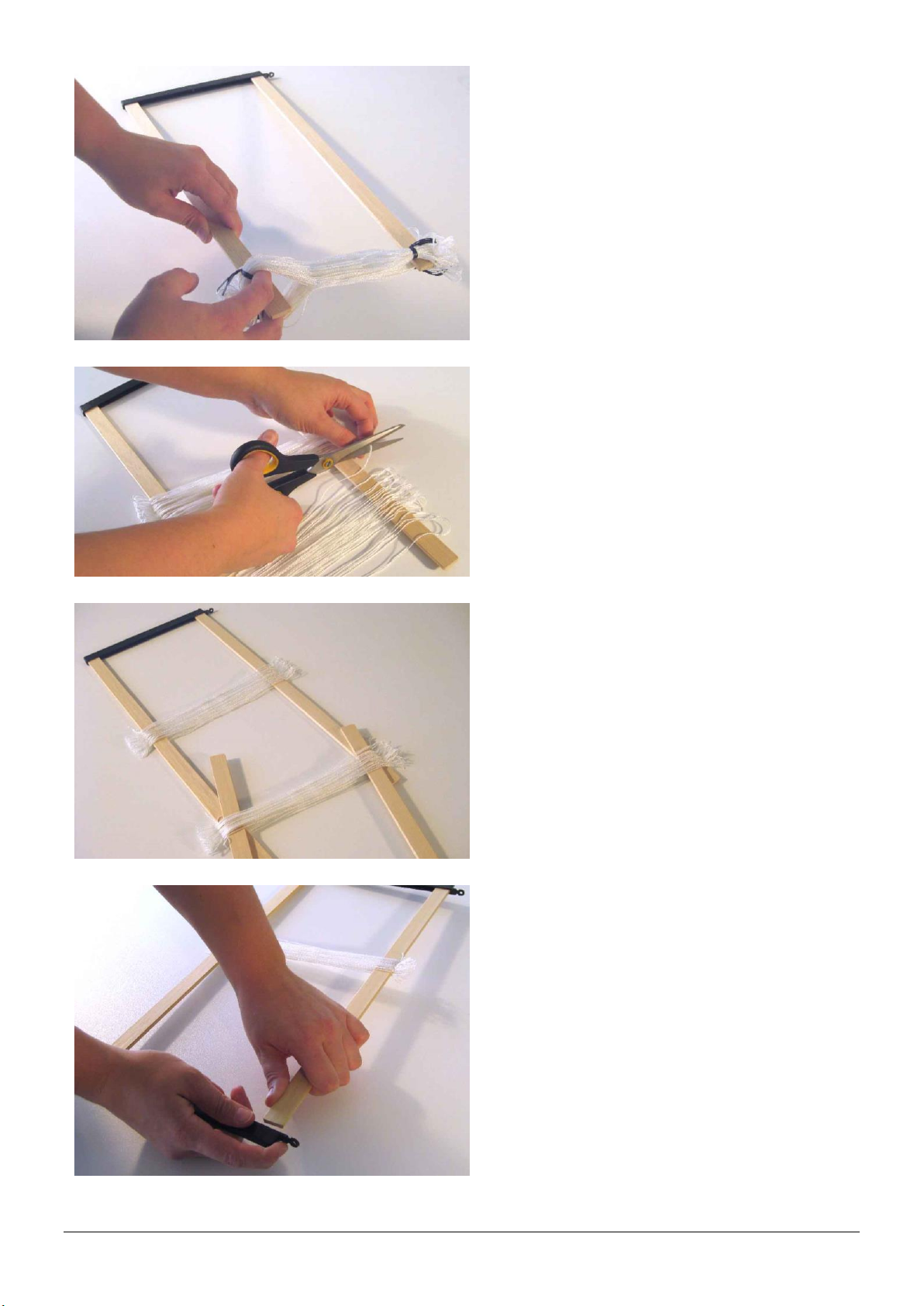

Louet Jane Assembly instructions

Other Louet Weaving manuals

Louet

Louet Spring User manual

Louet

Louet Kombo 70 4+4 User manual

Louet

Louet Megado Computer Dobby 2.0 User manual

Louet

Louet Kombo 40 4+4 User manual

Louet

Louet Spring Assembly instructions

Louet

Louet David-III Assembly instructions

Louet

Louet Delta User manual

Louet

Louet Erica User manual

Louet

Louet Erica User manual

Popular Weaving manuals by other brands

Schacht

Schacht CRICKET LOOM Assembly and Weaving Instructions

Schacht

Schacht FL3109 Assembly instructions

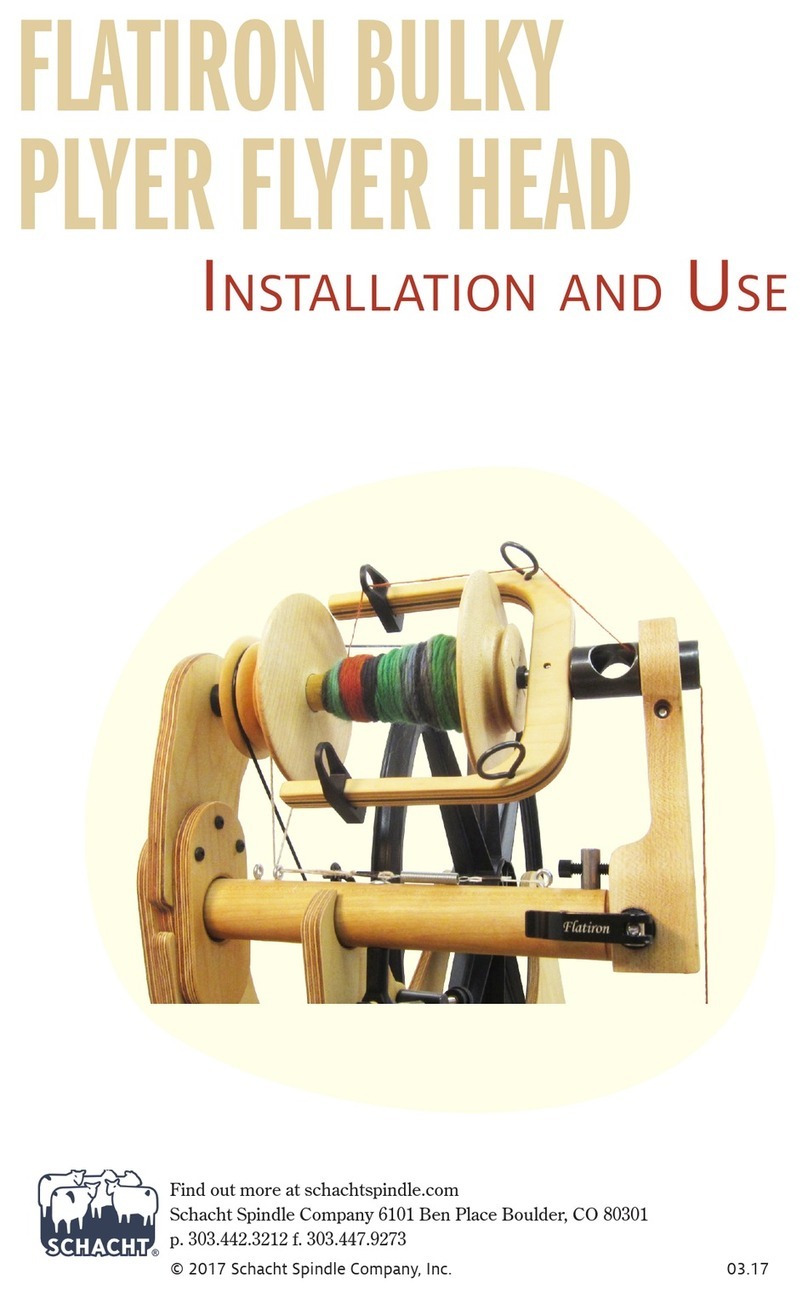

Schacht

Schacht FLATIRON BULKY PLYER FLYER HEAD Installation and use

Leclerc Looms

Leclerc Looms VOYAGEUR manual

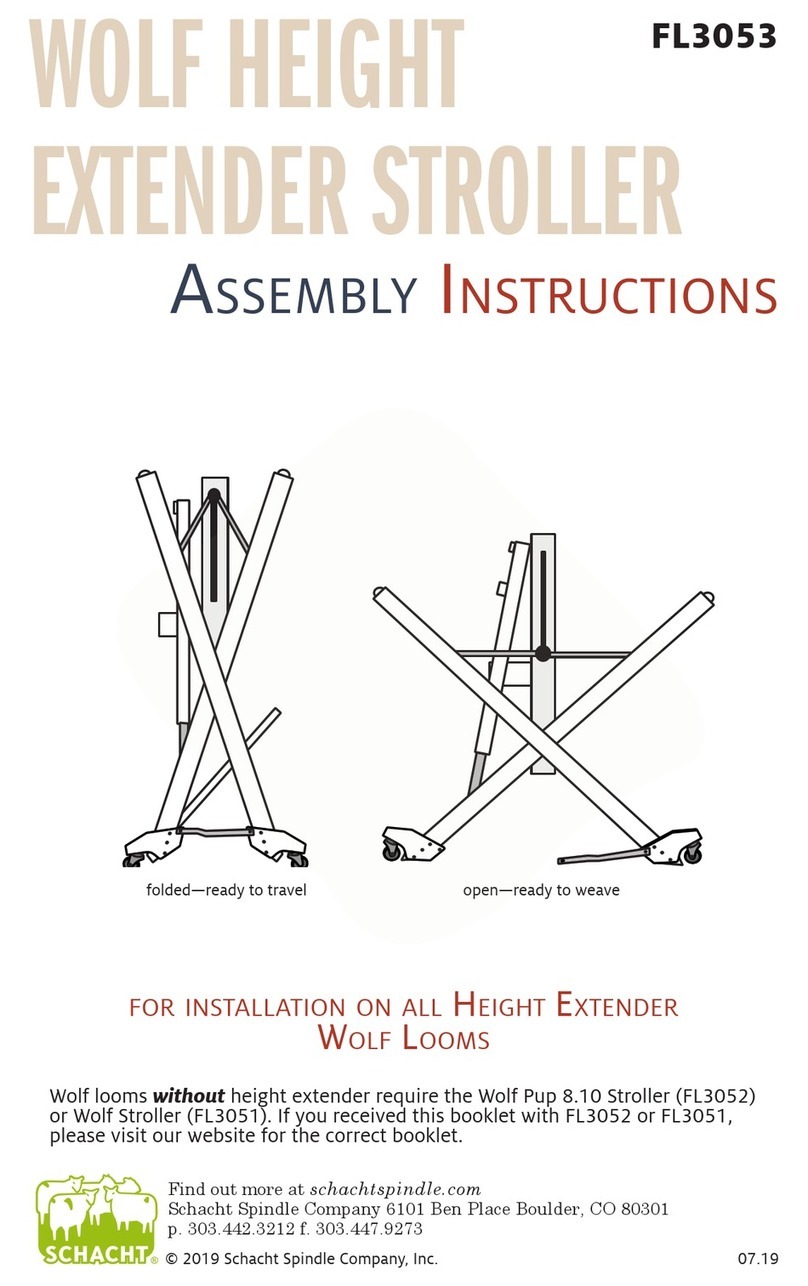

Schacht

Schacht FL3053 Assembly instructions

Schacht

Schacht WOLF PUP 8.10 HEIGHT EXTENDER Assembly instructions