2

daunting. Once the ties were made, there were

still problems as knots slipped or had to be

untied to adjust the cords. Fortunately this

drudgery is a thing of the past. The Texsolv

cords neither stretch nor require knots. The

Texsolv tie-up cords are attached to the lams

and can be simply hooked onto the treadles.

Changing the tie-up is easy and fast.

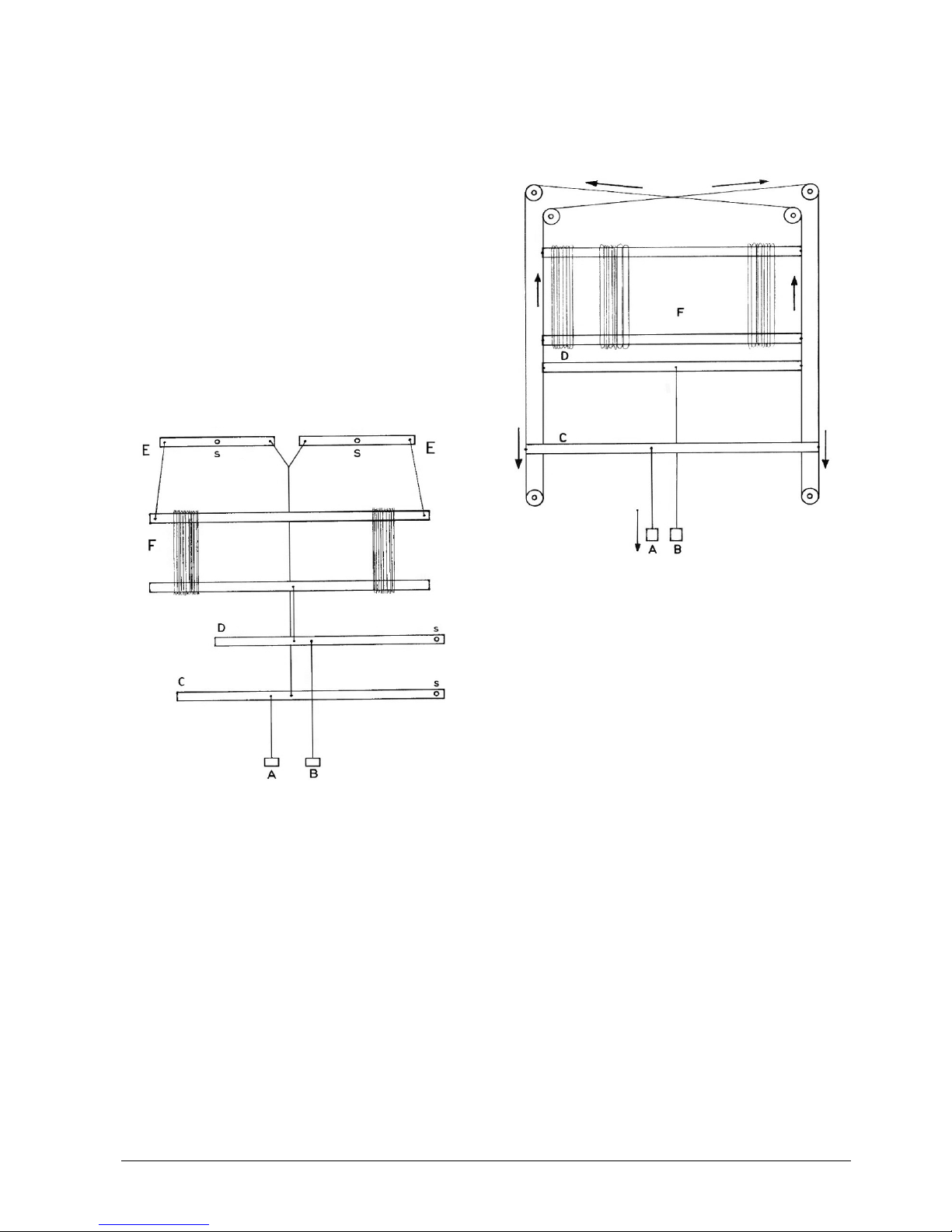

To improve the countermarch shed, to offer the

best shed a shaft action system can provide,

Louët invented an action system for another

part of the loom that holds the warp:

The moving breast beam, controlling the

warp tension

The moving breast beam allows the shafts to

move more easily in their opposite directions.

Looking at the diagram that shows the loom

from the side, you will see that a shed is giving

the warp a kind of parallelogram shape.

Imagine, the warp is made of inelastic material,

like metal wire, you will understand that making

a shed is only possible if the distance between

breast beam and back beam becomes smaller.

When this distance is fixed, as it is on other

looms, the shed depends completely on the

elasticity of the warp. When the shed becomes

wider, the tension on the yarns increases

(enormously, in case of a less elastic warp).

That causes heavy treadling and may damage

the warp.

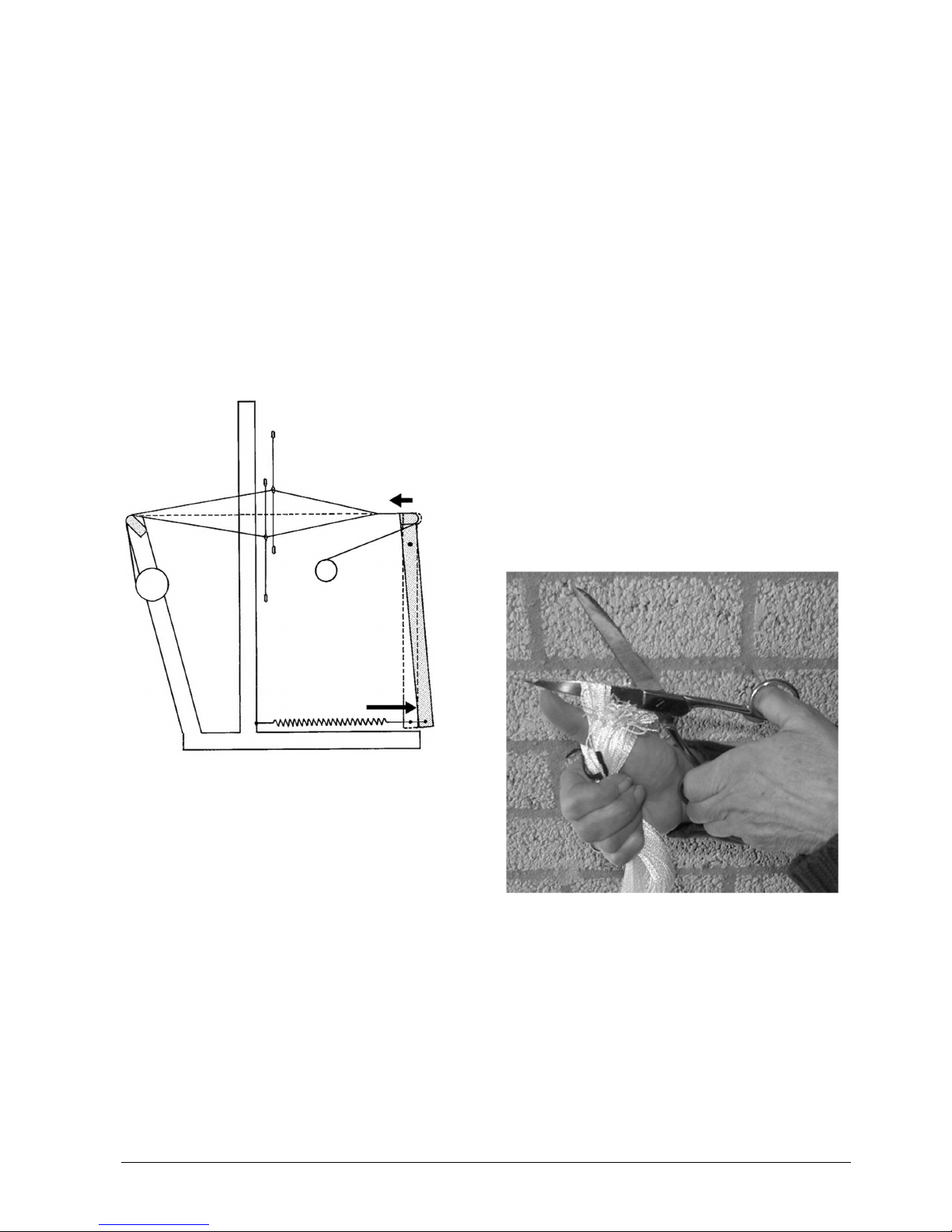

The moving breast beam is held by springs,

adjustable to give your warp the tension needed

for your project. Besides improvement of the

shed and protection of the warp, the springs

guarantee exactly the same warp tension each

time you have to advance the fabric.

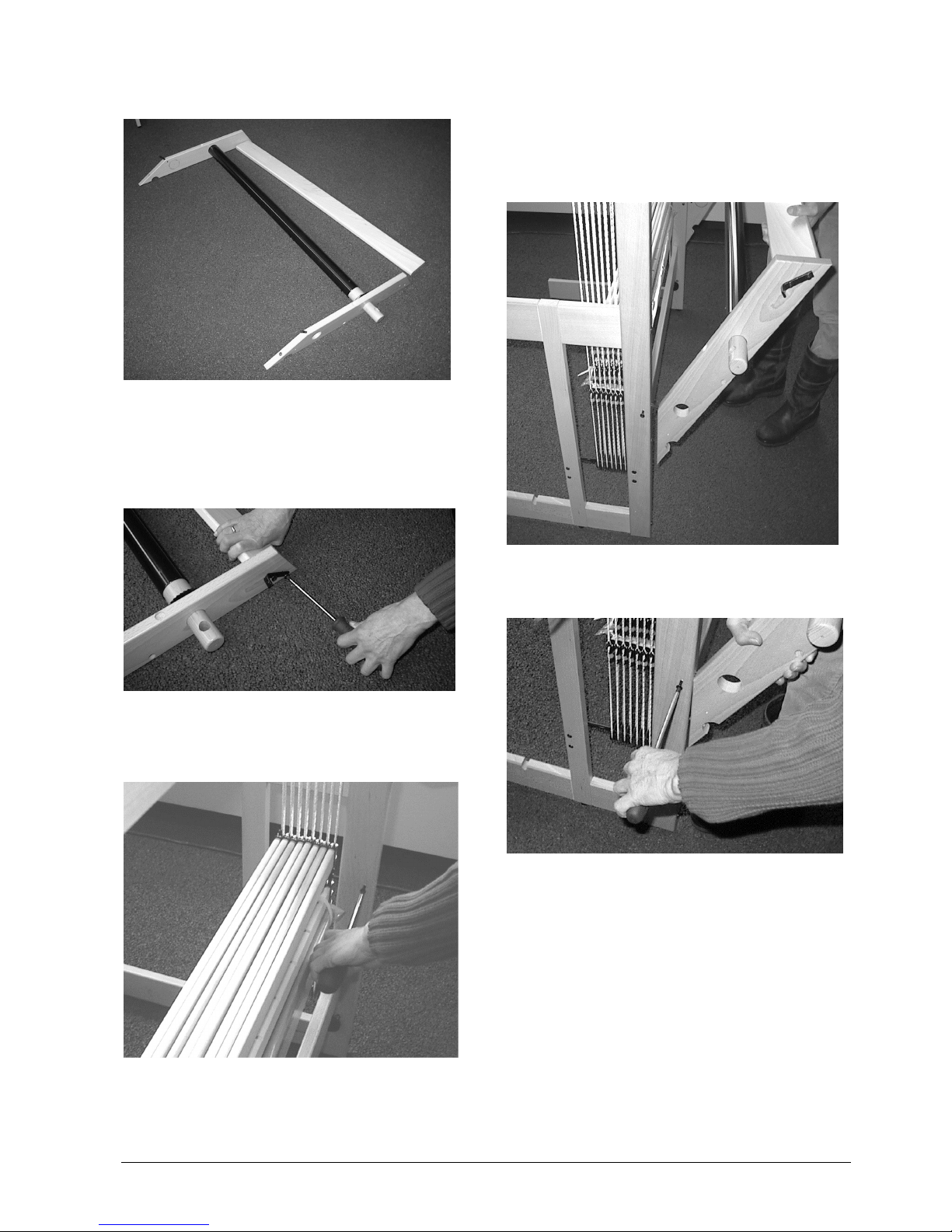

The Texsolv system

Texsolv cord and heddles are Swedish

products, crocheted out of polyester yarn.

Cotton heddles have the advantage of being

silent in use. Metal heddles, flat or wire, have

the advantage of having open eyes. Texsolv

heddles combine these features. A bundle of

Texsolv heddles is a continuous line of 100

heddles folded into a zigzag. Each bundle is

fastened in four places. These ties make it easy

to pass the shaft bars through the upper and

lower loop of the heddles. Do not remove the

ties from the bundles, until the heddles have

been slipped onto the shaft bars or the loops of

the bundles are inserted by sticks, to protect the

heddles from becoming entangled.

If you need to remove heddles from a shaft, first

tie them as they were originally. Use a pair of

sharp scissors to cut the heddles apart.

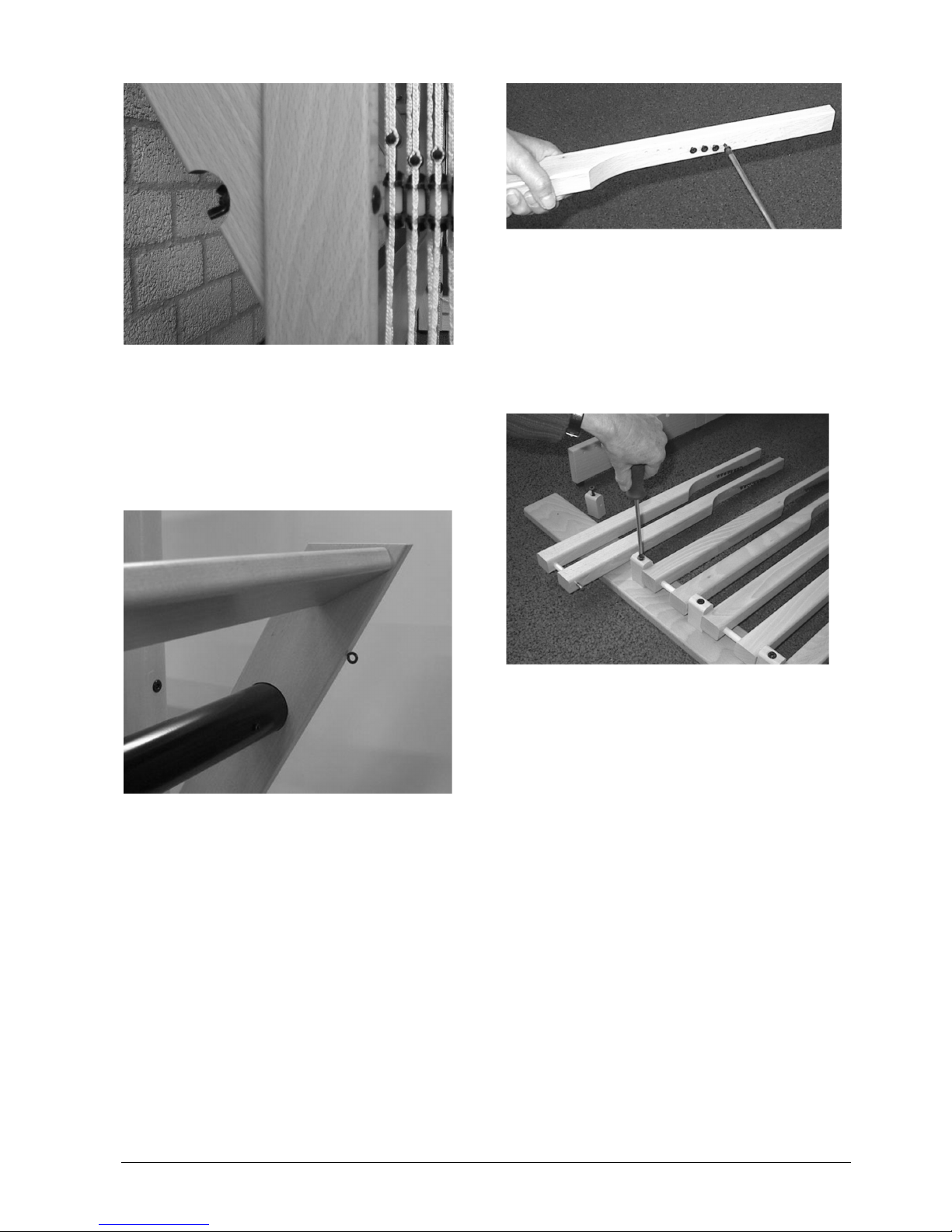

Texsolv cord consists of two cords, which are

connected every 12 mm, forming loops in

between. If needed, the cord should be cut

between two loops. To prevent unraveling, the

ends should be singed. Be careful not to overdo

the melting and be aware that melted polyester

is very hot and will burn the skin.

By mentioning the first or last loop in these

instructions, the loop is meant, next to the one

where the cord is cut, because when that loop

remains after cutting, it has no strength and

should not be used.