LSLV-H100 drives include a user-friendly keypad

designed exclusively for the Fan and Pump market

and satisfy various needs of customers.

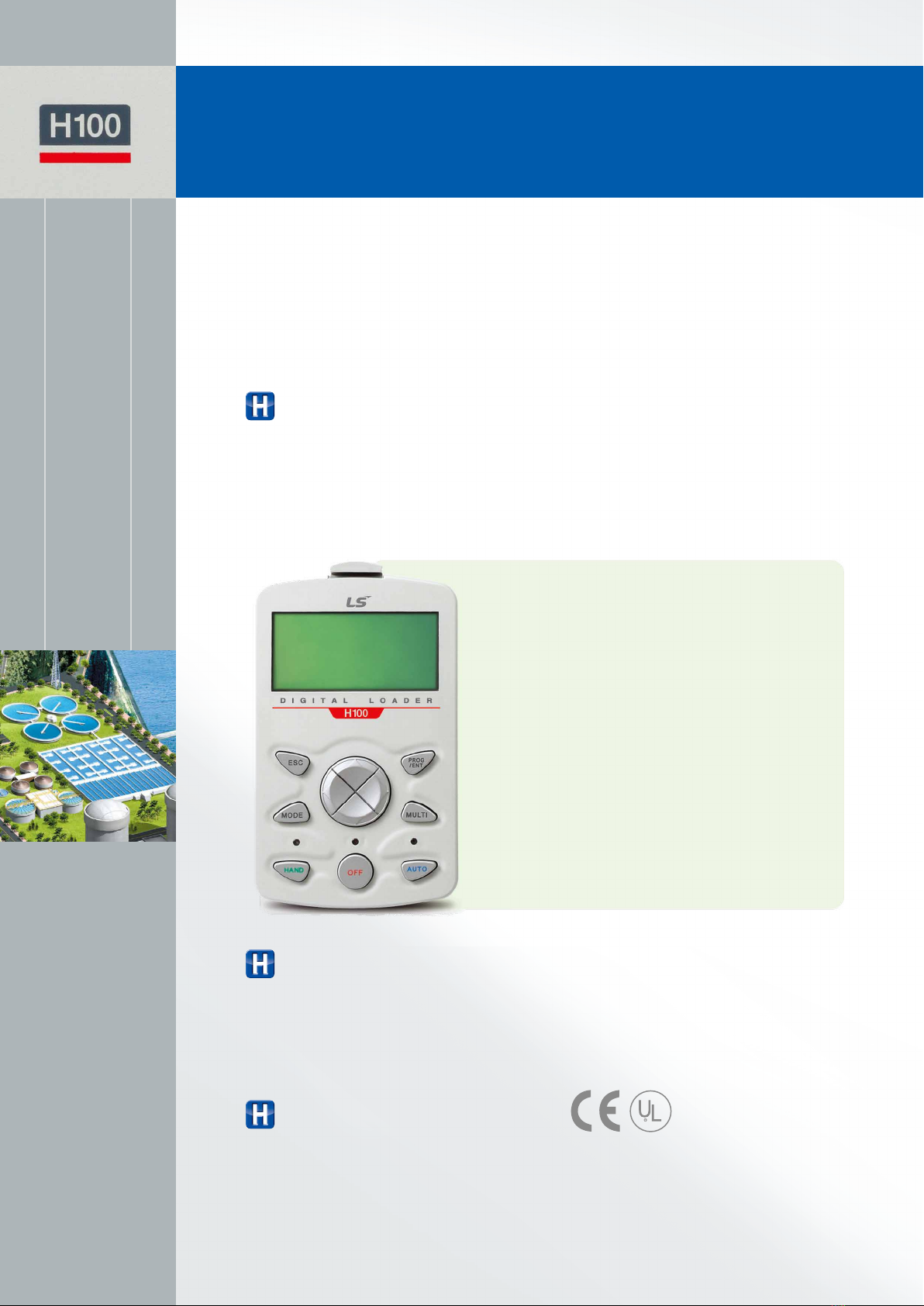

Maximized User Convenience

Used to issue commands, configure drive parameters, and for monitoring drive status

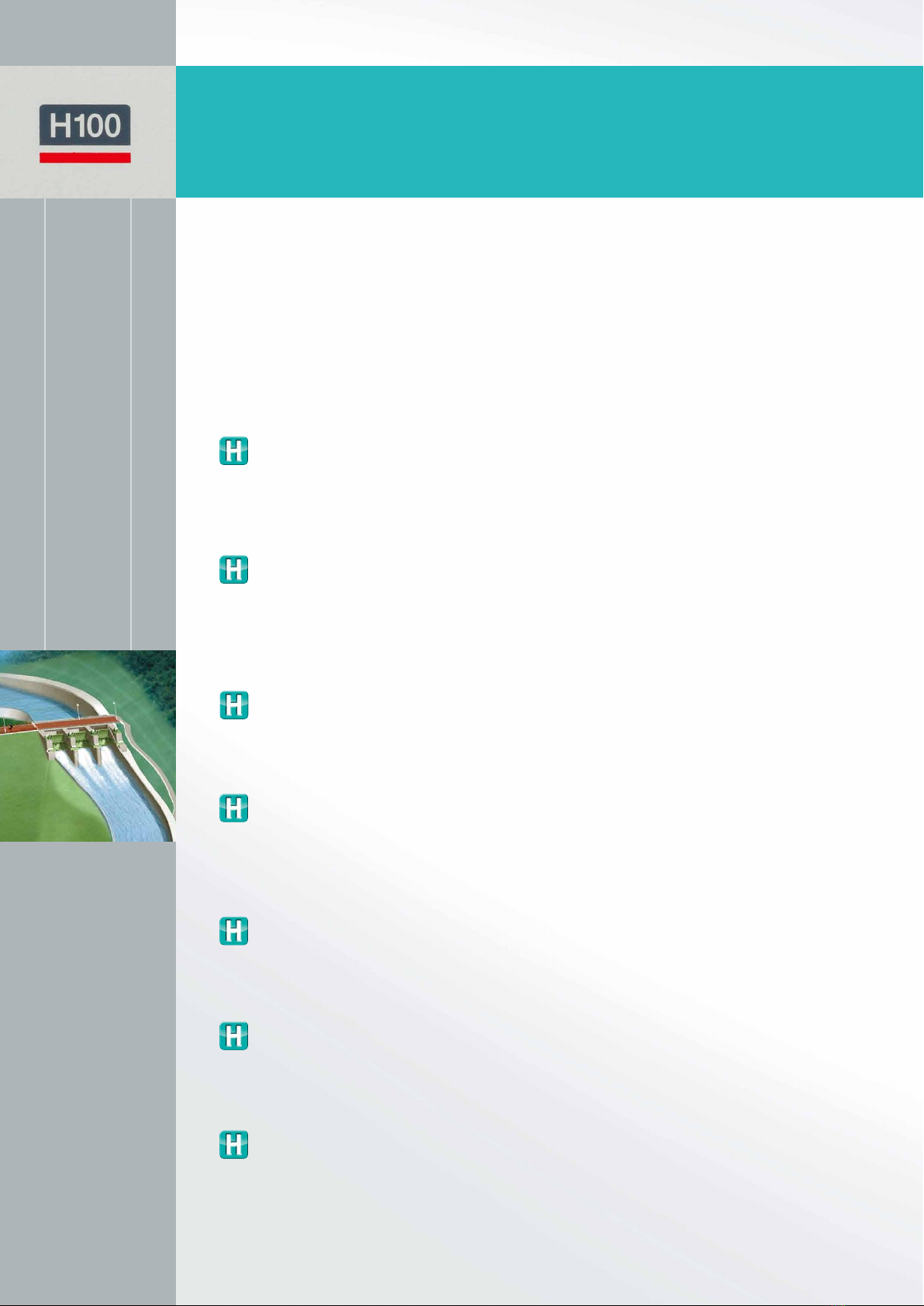

•HAND Mode (Local Control Mode) or AUTO Mode (Remote Control Mode) can be selected.

- HAND Mode: Used when selecting frequency or run/stop commands.

- AUTO Mode: Drive operated using the keypad, multifunctional terminal block and

communications.

•Fault Status Monitoring

Keypad Exclusive for Fan and Pump

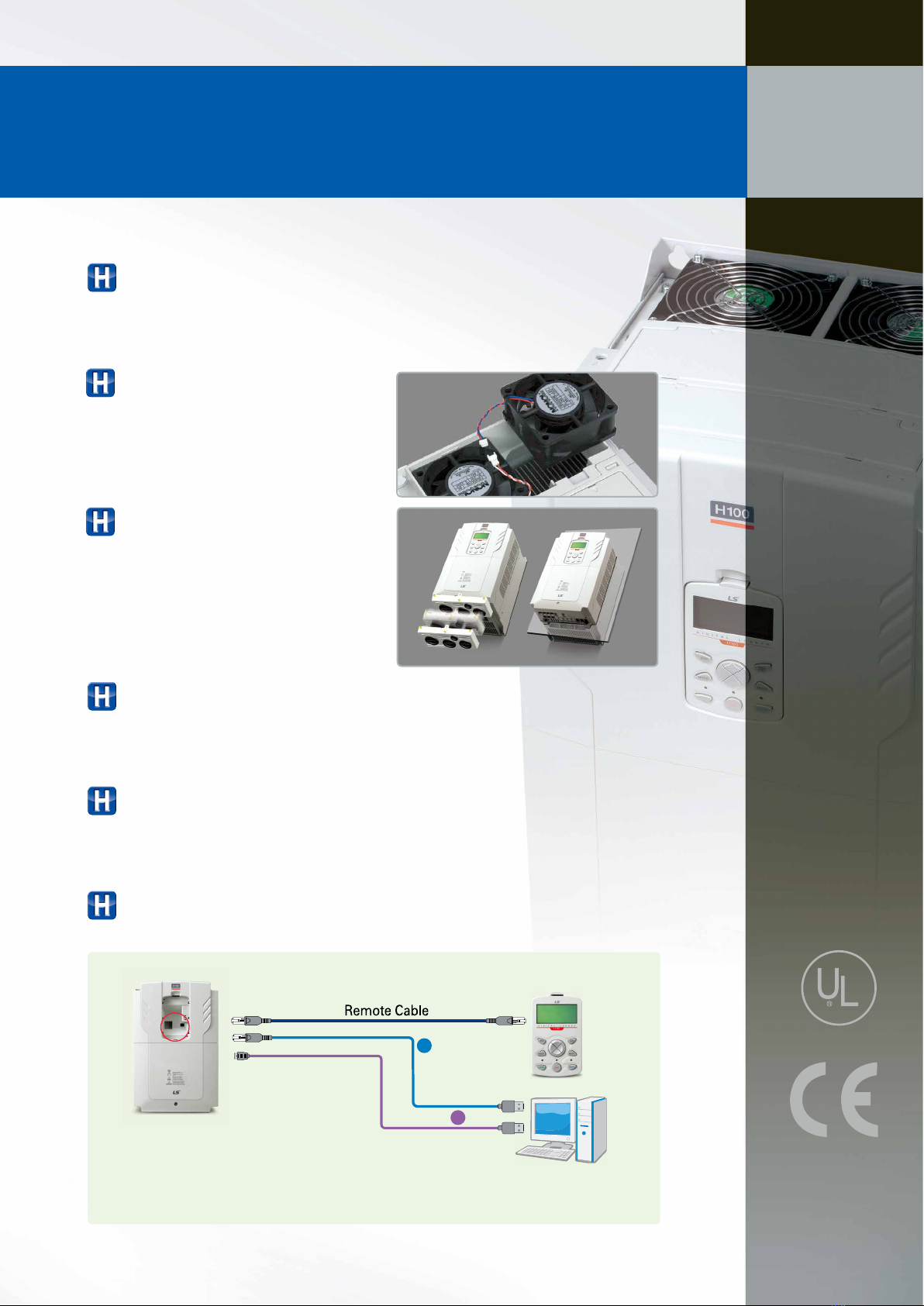

A built-in EMC filter to respond to the specifications for noise reduction

•400V 0.75~30kW, 110~500kW Built-in as default (C3)

•400V 37~55kW Built-in option can be selected (C3)

※ 75~90kW satisfies EMC specifications even without a filter.

Built-in EMC Filter

Energy Saving Drive

UL Plenum Rated

(American standards for conditioner fire safety)

※ Suitable for compartment for air handling/air conditioning

Global Specifications Compliant

04_ LS ELECTRIC

Cancel (ESC) Key

•While in the Edit state, previously saved data are used

•When pressed while switching codes within the group,

it is switched to the very first mode of group.

•When pressed while switching modes, it reverts back to the

monitor mode.

Program (PROG/ENT) Key

•When pressed once, it is changed to Parameter Edit state.

•When pressed after changes, the changed data are saved.

Left/Right Key

•It is used to switch between groups.

(Cursor is used under the Edit state.)

Up/Down Key

•It is used to switch between

codes and edit data values.

Hand (HAND) Key

•It is used to select Keypad

(HAND) operation

•Speed control

(HAND key UP/DOWN)

Auto (OFF) Key

•Off mode or fault reset

Multifunction (MULTI) Key

•It is used to register user codes.

Auto (AUTO) Key

•It is used to select AUTO operation.